PriceList for Lost Wax Casting Parts – Brass CNC Machining Parts – RMC Foundry Detail:

Brass CNC machining parts produced by CNC machining centers from China casting company.

▶ Equipment for Precision Brass Machining Components:

• Convertional Machining Machines: 20 sets.

• CNC Machines: 60 sets.

• 3-Axis Machining Center: 10 sets.

• 4-Axis Machining Center: 5 sets.

• 5-Axis Machining Center: 2 sets

▶ Precision Machining Capabilities

• Max Size: 1,500 mm × 800 mm × 500 mm

• Weight Range: 0.1 kg - 500 kg

• Annual Capacity: 10,000 tons

• Accuracy: As per standards: .... or on request. Minimum ±0.003 mm

• Holes to ±0.002 mm dia.

• Flatness, Roundness and Straightness: As per standards or on request.

▶ Our In-house Machining Workshop Give Our Customers the Following Advantages:

• Short lead time for machined castings and forgings.

• Only one contact for castings, forgings and machining.

• Fast transmission between foundry and machining workshop.

• Well communication inside our systems and with our customers.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

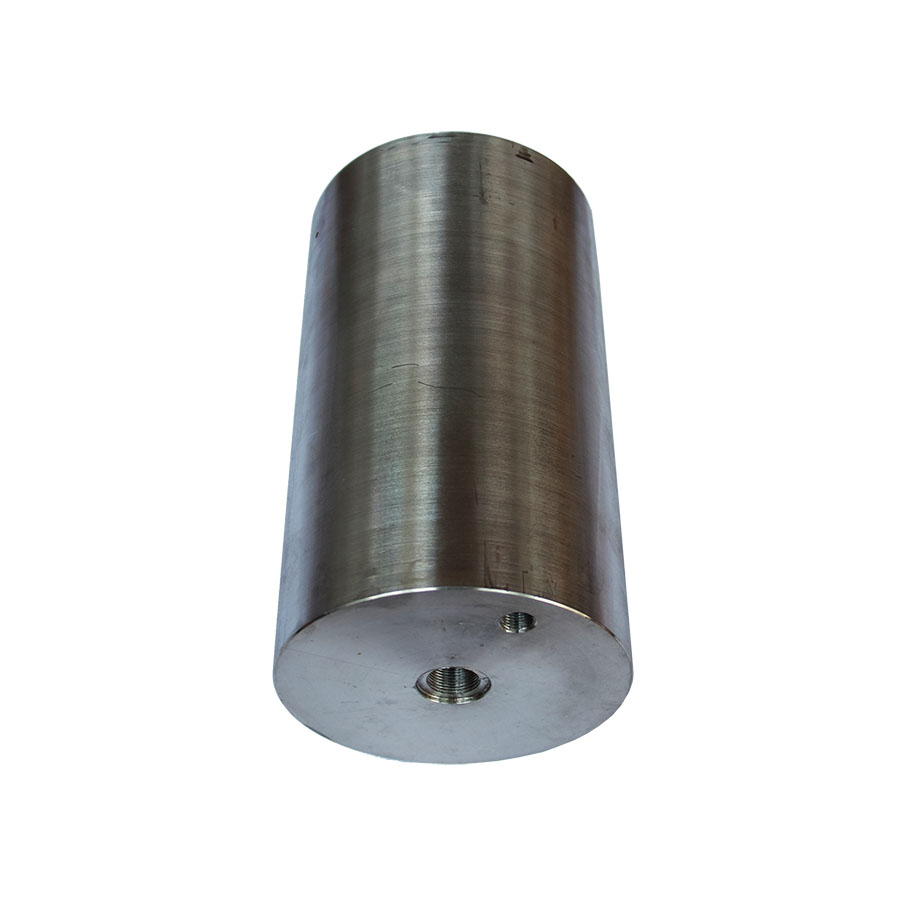

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for PriceList for Lost Wax Casting Parts – Brass CNC Machining Parts – RMC Foundry, The product will supply to all over the world, such as: Belgium , Kuala Lumpur , Namibia , At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

-

Wholesale Steel Investment Casting Manufacturer...

-

OEM/ODM China Steel Precision Casting - Stainl...

-

Discount Price Gray Iron V Process Casting Foun...

-

Ordinary Discount Metal Casting Foundry - Duct...

-

Special Price for Aluminium Precision Casting -...

-

Good quality Ductile Iron Vacuum Casting Foundr...