-

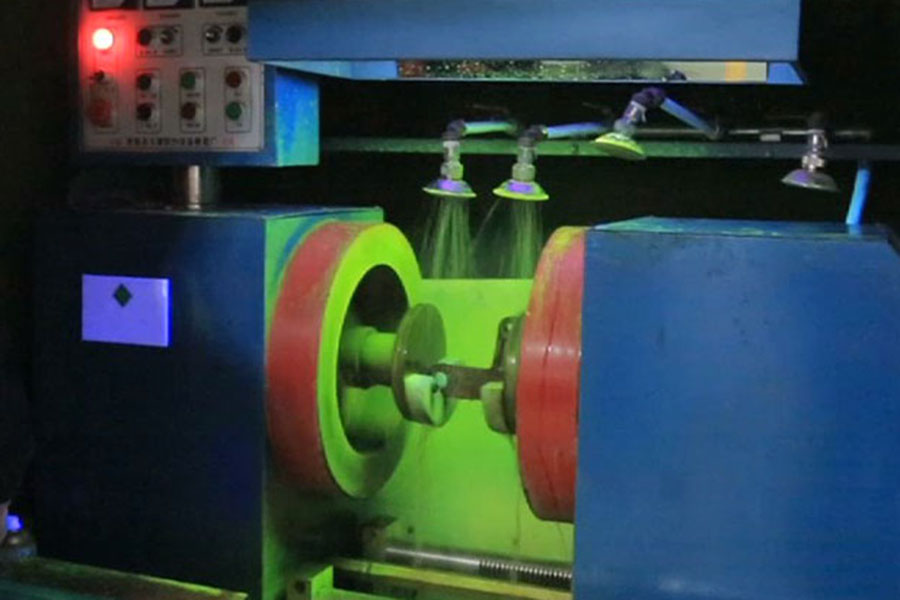

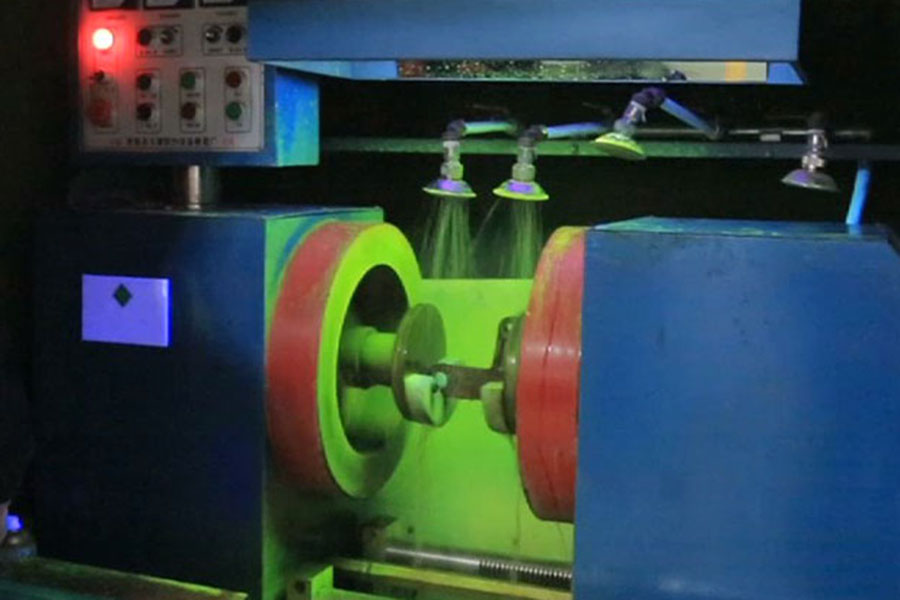

Magnetic Particle Inspection of Casting Internal Defects

Magnetic particle inspection is a detection method that uses the properties of ferromagnetic materials (such as steel, iron, cobalt, nickel, etc.) to be magnetized. When the metal casting is strongly magnetized by the magnetic field, if there is a defect perpendicular to...Read more -

Radiographic Inspection of Castings

Radiographic Inspection of Castings 1. The basic principle of radiography In the process of penetrating the casting, X-ray or γ-ray interacts with the material, and its intensity is attenuated by absorption and scattering. Images with varying degrees of blackness ...Read more -

Silica Sol Binder In Investment Casting

The choice of silica sol coating will directly affect the surface roughness and dimensional accuracy of investment castings. Silica sol coatings generally can directly select silica sol with a mass fraction of silica of 30%. The coating process is simple and the operatio...Read more -

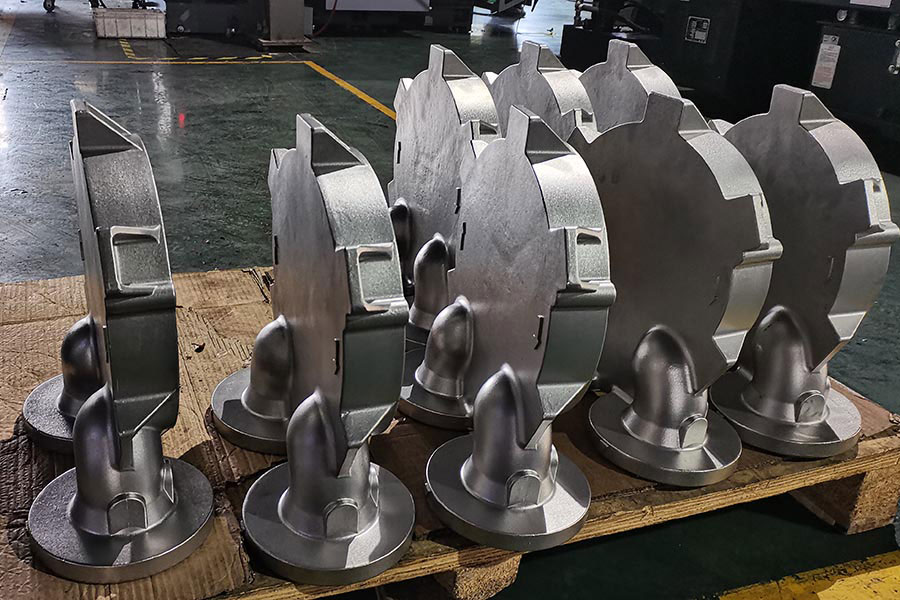

Chills for Metal Casting

Chill is the chilled material placed inside the cavity, the surface of the cavity and the inside of the mold in order to speed up the local cooling rate of the casting. The chills are used in conjunction with the gating system and the riser system to control the solidifi...Read more -

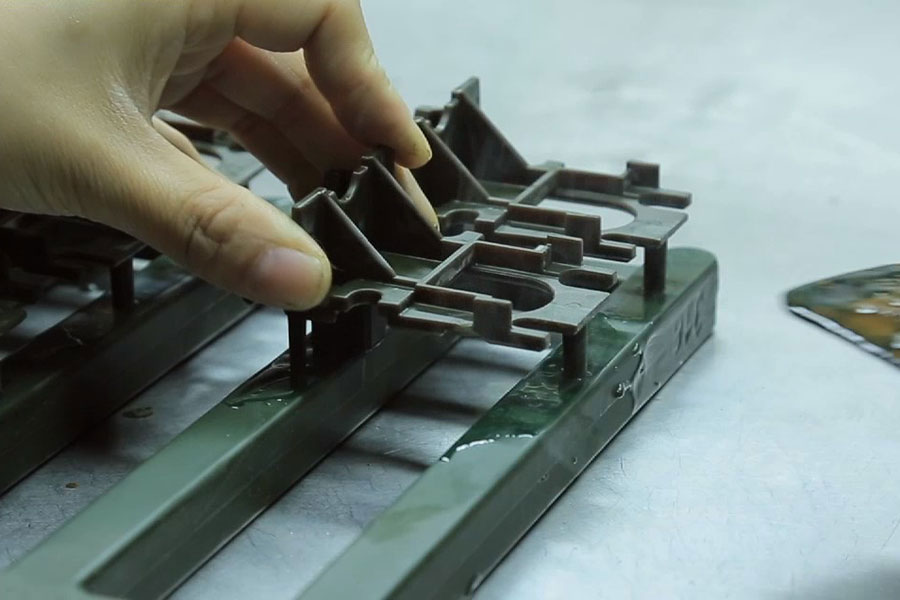

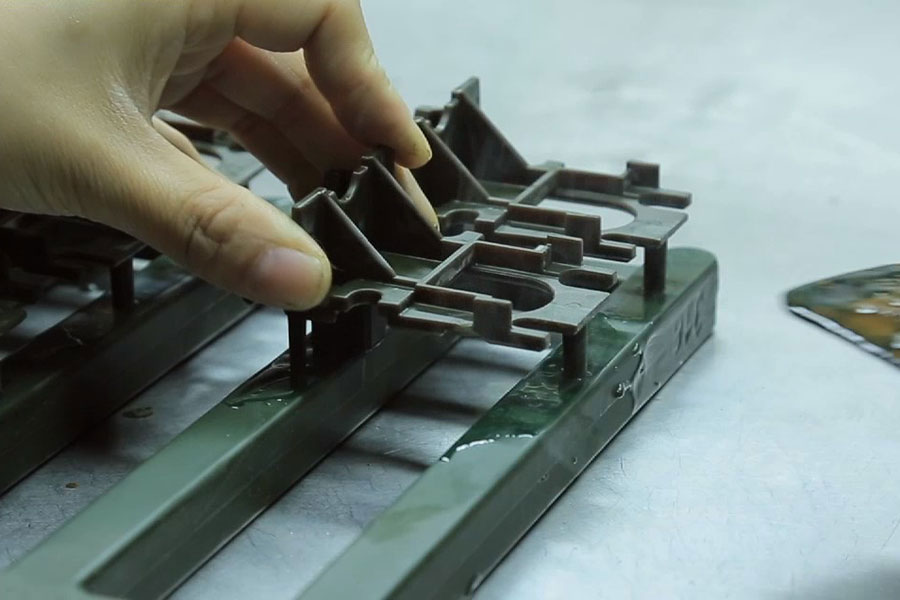

How to Assemble Wax Trees During Lost Wax Casting Process

During lost wax casting process, to assembly the wax tree(s) is an important work. It has some influence on the quality of the raw castings and the fluidity of the molten metals, especially for the steel alloys. Here in the following we will try to introduce the basic s...Read more -

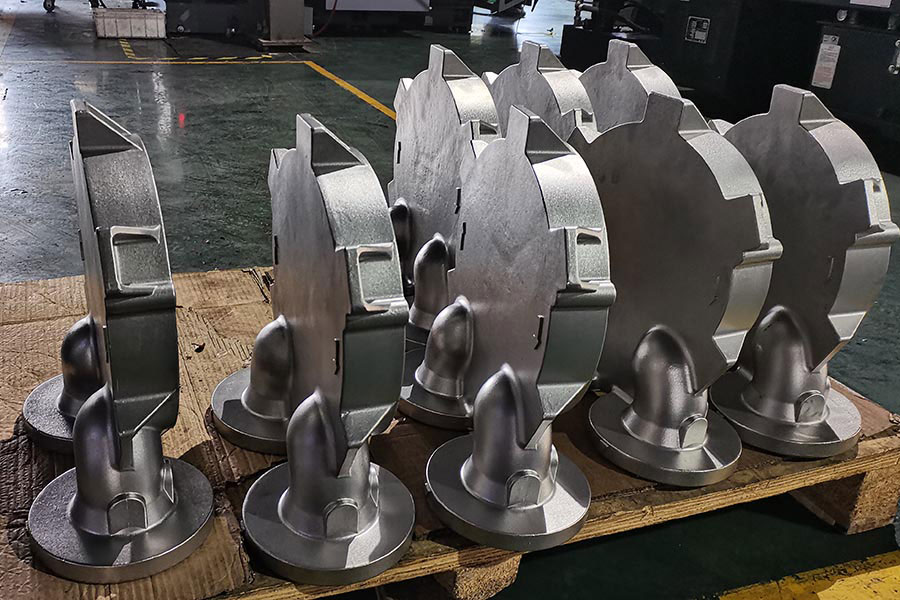

Precision Casting for Stainless Steel Castings

Precision casting is also called investment casting. This casting process minimizes or does not cut during the casting process. It is a casting method with a wide range of applications, high dimensional accuracy of the casting, and excellent surface quality. It is not in...Read more -

Heat Treatment of Austenitic Stainless Steel Castings

The as-cast structure of austenitic stainless steel castings is austenite + carbide or austenite + ferrite. Heat treatment can improve the corrosion resistance of austenitic stainless steel castings. Equivalent Grade of Austenitic Stainless Steel AISI ...Read more -

Heat Treatment of Martensitic Stainless Steel Castings

Martensitic stainless steel refers to a type of stainless steel whose microstructure is mainly martensite. The chromium content of martensitic stainless steel is in the range of 12% - 18%, and its main alloying elements are iron, chromium, nickel and carbon. Martensitic ...Read more -

Chemical heat treatment of steel castings

The chemical heat treatment of steel castings refers to placing the castings in an active medium at a certain temperature for heat preservation, so that one or several chemical elements can penetrate the surface. Chemical heat treatment can change the chemical compositio...Read more -

No-Bake Sand Casting Process

Sand molds used in sand casting are classified into three types: clay green sand, clay dry sand, and chemically hardened sand according to the binder used in the sand and the way it builds its strength. No-bake sand is foundry sand th...Read more -

Normalization Heat Treatment for Steel Castings

Normalizing, also known as normalization, is to heat the workpiece to Ac3 (Ac refers to the final temperature at which all free ferrite is transformed into austenite during heating, generally from 727°C to 912°C) or Acm (Acm is In actual heating, the critical temperature...Read more -

Description, Reasons and Remedies of Common Sand Casting Defects

There are many reasons for sand casting defects in real sand casting process. But we can find the exact reasons by analyzing the defects inside and outside. Any irregularity in the moulding process causes defects in castings which may sometimes be tolerated. Usually the ...Read more