Duplex Stainless Steel (DSS) refers to a group of stainless steel with metallographic microstructure of both ferrite and austenite each accounting for about 50%. Generally, the content of less phases needs to be at least 30%. In the case of low carbon content, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some duplex stainless steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N. The DSS has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and ductility, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining brittleness, high thermal conductivity, and superplasticity as ferrite stainless steel. Compared with austenitic stainless steel, DSS has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel. Available grades of duplex stainless steel cast by lost wax investment casting : 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

-

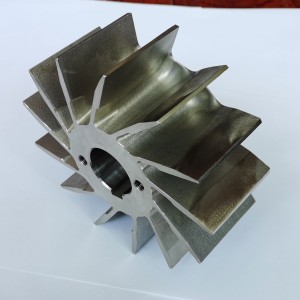

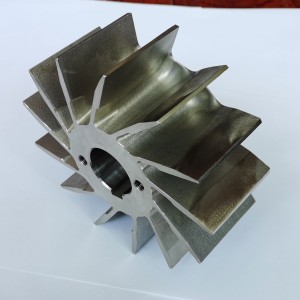

Duplex Stainless Steel Open Impeller by Investment Casting and CNC Machining

-

Duplex Stainless Steel Lost Wax Casting

-

Super Duplex Stainless Steel Investment Casting Impeller

-

Custom Valve Housing of Cast Duplex Stainless Steel

-

Custom Duplex Stainless Steel CD3MWCuN Investment Casting Product

-

Duplex Stainless Steel 2205 / 2507 Investment Casting

-

Duplex Stainless Steel Precision Investment Casting Product