Alloy steel castings are very extensive in terms of metal and alloy selection. For example, the cast steel covers a wide range of alloys such as low carbon steel, medium carbon steel, high carbon steel, alloy steel, high alloy steel, stainless steel, duplex stainless steel, precipitation hardening stainless and other special steel alloys.

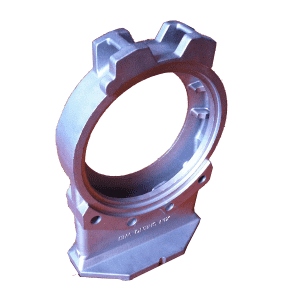

Steel castings are combination of casting molding process and steel material metallurgy. They can not only have complex structure that are difficult to obtain by other forming processes, but also maintain the unique properties of steel, so the steel casting parts have a high important position in engineering structural materials. In most foundries, steel castings are mainly produced through these several casting processes: lost wax casting, lost foam casting, vacuum casting, sand casting and resin coated sand casting.

Mechanical Properties of Alloy Steel 20Cr and Alloy Steel 35CrMo |

||

| Content | Mechanical Properties | |

| 20Cr (≥) | 35CrMo | |

| sв (tensile strength), MPa | ≥ 835 | ≥ 980 |

| sT (yield strength), MPa | ≥ 540 | ≥ 835 |

| d5 (elogation), | ≥ 10 | ≥ 12 |

| y (сontraction) | ≥ 40 | ≥ 45 |

| KCU (impact) , kJ/㎡ | ≥ 47 | ≥ 63 |

Performance Characteristics of Alloy Steel Castings

- • Poor fluidity and volume shrinkage and linear shrinkage are relatively large

- • Comprehensive mechanical properties are relatively high. Compressive strength and tensile strength are equal

- • Poor shock absorption and high notch sensitivity

- • Low carbon steel castings have relatively good weldability.

Structural Characteristics of Alloy Steel Castings

- • The minimum wall thickness of steel castings should be greater than the minimum wall thickness of gray cast iron. It is not suitable to design too complex castings

- • Steel castings have relatively large internal stress and are easy to bend and deform

- • The structure should minimize hot nodes and conditions for sequential solidification should be created

- • The fillet of the connecting wall and the transition section of different thickness are larger than those of cast iron

- • Complicated castings can be designed into a casting + welding structure to facilitate casting production