China OEM custom aluminium alloy investment casting products. Available services: casting, heat treatment, surface treatment, CNC machining and testing.

Investment casting process uses a expendable pattern of wax, which is coated with a ceramic shell. The wax replicas inside the ceramic shells would be removed by using an autoclave or furnace. Metal is then poured into the remaining cavity, which is the same as the desired casting.

Available Raw Materials for Investment Casting, Lost Wax Casting Process:

• Carbon Steel: AISI 1020 - AISI 1060,

• Alloy Steel: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4404, 1.4301 and other stainless steel grade.

• Brass & Copper.

• Aluminium Alloy.

• Other Materials and Standards on request

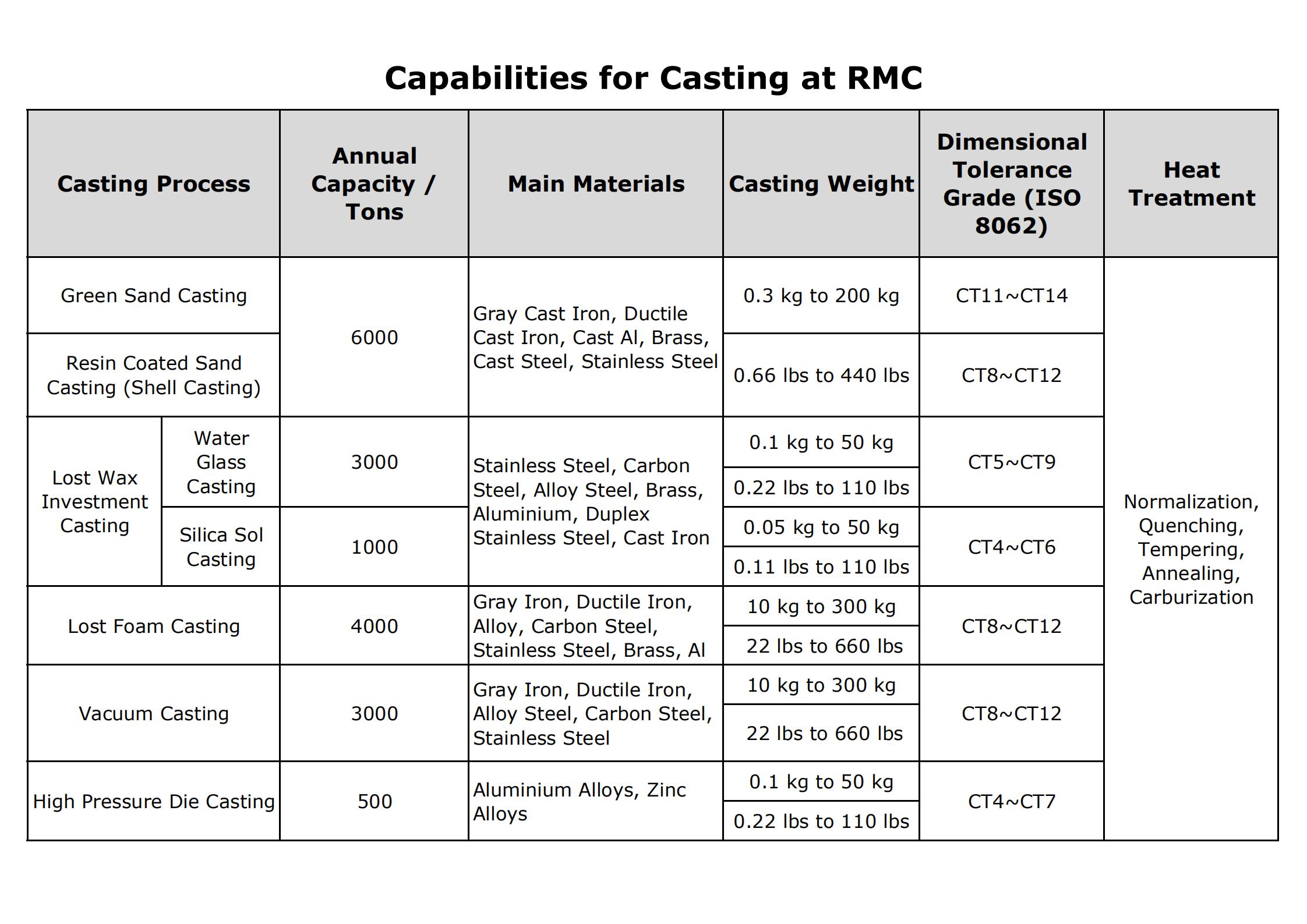

Capabilities of Investment Casting Foundry:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

Main Production Procedure:

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

The precision machining workshop at RMC takes care probably the most important step in the supply chain after casting. State-of-the-art vertical and horizontal CNC machining centers and other CNC machines could make sure the accuracy of the castings and guarantee the machined castings are finished on time. All machines are well-organized and taken into production at high production effeciency and good cost-effective mothods. If needed, all the machined dimensions could be measured by the CMM and the related reports could be issued as per customer's requirements.

Applications of Our Custom Casting and Machining Parts:

1. Automobile Parts: Brake Disc, Connect Rod, Drive Axle, Drive Shaft, Control Arm, Gearbox Housing, Gearbox Cover, Clutch Cover, Clutch Housing, Wheels, Filter Housing, C.V. Joint Housing, Lock Hook.

2. Truck Parts: Rocker Arms, Transmission Gearbox, Drive Axles, Gear Housing, Gear Cover, Towing Eye, Connect Rod, Engine Block, Engine Cover, Joint Bolt, Power Takeoff, Crankshaft, Camshaft, Oil Pan.

3. Hydraulic Parts: Hydraulic Cylinder, Hydraulic Pump, Gerotor Housing, Vane, Bushing, Hydraulic Tank, Hydraulic Cylinder Head, Hydraulic Cylinder Triangle Bracket.

4. Agricultural Machinery and Tractor Parts: Gear Housing, Gear Cover, Connect Rod, Torque Rod, Engine Block, Engine Cover, Oil Pump Housing, Bracket, Hanger, Hook, Bracket.

5. Rail Trains and Freight Cars: Shock Absorber Housing, Shock Absorber Cover, Draft Gear Housing, Draft Gear Cover, Wedge and Cone, Wheels, Brake Systems, Handles, Guids.

6. Construction Machinery Parts: Gear, Bearing Seat, Gear Pump, Gearbox Housing, Gearbox Cover, Flange, Bushing, Boom Cylinder, Support Bracket, Hydraulic Tank, Bucket Teeth, Bucket.

7. Logistics Equipment Parts: Wheels, Caster, Bracket, Hydraulic Cylinder, Forklift Spare Parts, Lock Case,

8. Valve and Pump Parts: Valve Body (Housing), Butterfly Valve Disc, Ball Valve Housing, Flange, Connector, Camlock, Open Impeller, Close Impeller, Pump Housing (Body), Pump Cover.

Post-Machining Services