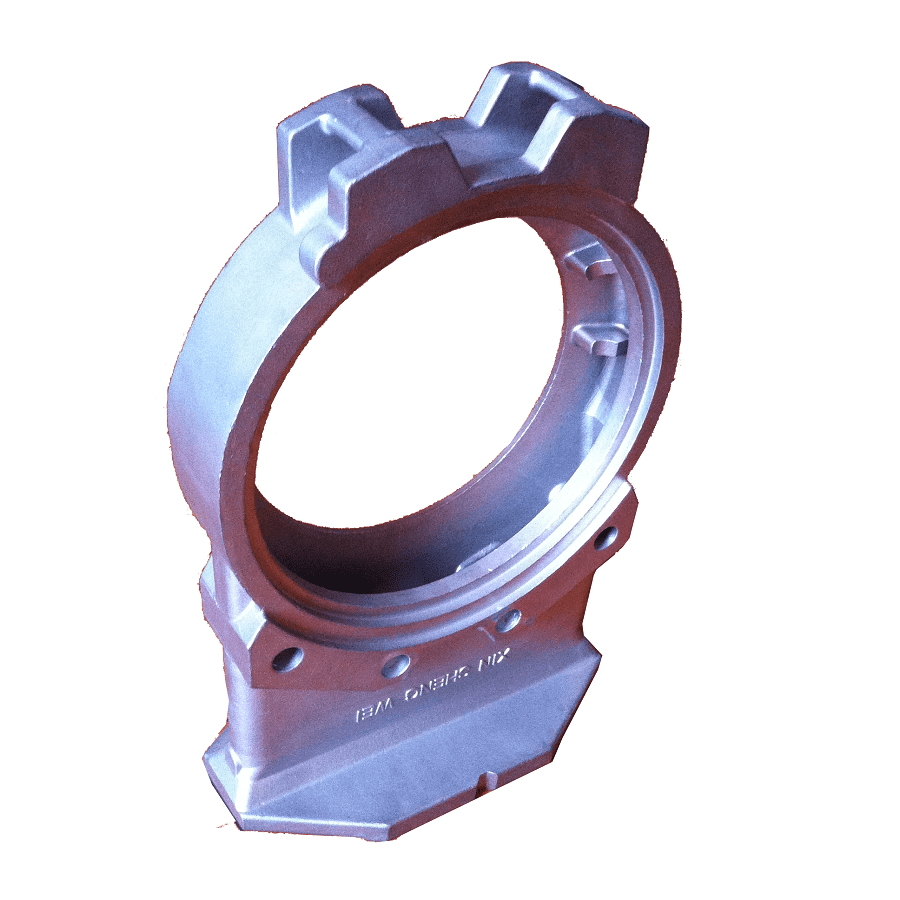

Trending Products Gray Iron Casting Company - Stainless Steel CNC Precision Machining – RMC Foundry Detail:

Stainless Steel CNC Precision Machining parts from China Machining Company.

State-of-the-art vertical and horizontal CNC machining centers and other CNC machines could make sure the accuracy of the castings and guarantee the machined castings are finished on time. All machines are well-organized and taken into production at high production effeciency and good cost-effective mothods. If needed, all the machined dimensions could be measured by the CMM and the related reports could be issued as per customer’s requirements.

▶ Equipment for Precision Machining Components:

• Convertional Machining Machines: 20 sets.

• CNC Machines: 60 sets.

• 3-Axis Machining Center: 10 sets.

• 4-Axis Machining Center: 5 sets.

• 5-Axis Machining Center: 2 sets

▶ Precision Machining Capabilities

• Max Size: 1,500 mm × 800 mm × 500 mm

• Weight Range: 0.1 kg – 500 kg

• Annual Capacity: 10,000 tons

• Accuracy: As per standards: …. or on request. Minimum ±0.003 mm

• Holes to ±0.002 mm dia.

• Flatness, Roundness and Straightness: As per standards or on request.

▶ Available Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for Precision Machining Components:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Steel Alloys from standard grades to special grades on request.

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex, Corrosion-resistant Steel, High-temperature Steel.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Trending Products Gray Iron Casting Company - Stainless Steel CNC Precision Machining – RMC Foundry, The product will supply to all over the world, such as: Lesotho , Berlin , Romania , Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

-

PriceList for Carbon Steel Shell Casting - All...

-

Discountable price Carbon Steel Casting Supplie...

-

High definition Permanent Mold Casting - Resin...

-

Manufacturer for Alloy Steel Lost Wax Casting -...

-

Manufacturing Companies for Carbon Steel Sand C...

-

OEM/ODM China China Machining Supplier - Non F...