Hot Selling for Stainless Steel Sand Casting Foundry - Gray Iron Sand Casting – RMC Foundry Detail:

OEM Custom Gray Iron Sand Casting from China Foundry with CNC Machining.

Raw Materials Available for Sand Casting

• Gray Iron: GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350

• Ductile Iron: GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2

• Aluminium and Their Alloys

• Other Materials and Standards on request

Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 5,000 tons – 6,000 tons

• Tolerances: On Request.

Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 8,000 tons – 10,000 tons

• Tolerances: On Request.

Main Production Procedure

Patterns & Tooling Design → Making Patterns → Moulding Process → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

Sand Casting Inspection Capabilities

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

General Commerial Terms

• Main work flow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Lead time: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

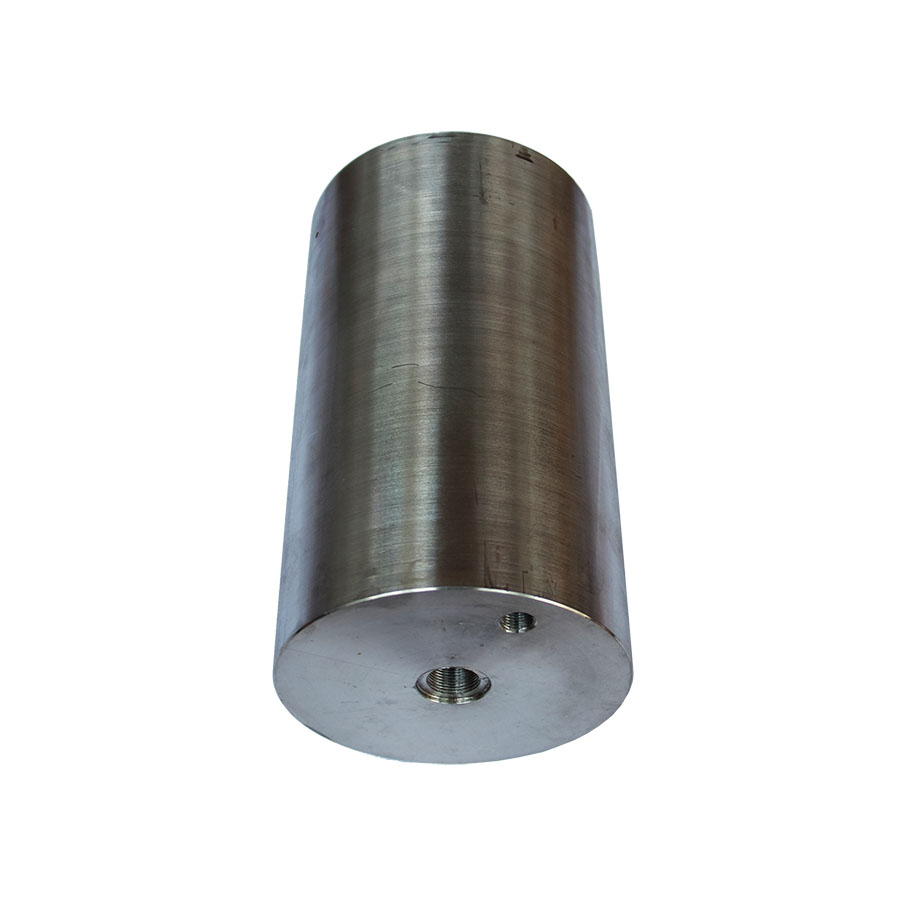

Product detail pictures:

Related Product Guide:

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for Hot Selling for Stainless Steel Sand Casting Foundry - Gray Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Nepal , Honduras , Sri Lanka , Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Leading Manufacturer for Lost Wax Casting Suppl...

-

Leading Manufacturer for Lost Wax Casting Suppl...

-

2020 Good Quality Lost Foam Casting Company - ...

-

Factory wholesale No Bake Molding Casting - Br...

-

Special Price for Stainless Steel Lost Wax Cast...

-

factory Outlets for Iron Casting Factory - Sta...