High Quality Gray Iron Lost Foam Casting - Custom Lost Foam Casting Factory – RMC Foundry Detail:

Custom lost foam castings could be made by according to the drawings and requirements with quick production and competitive prices. Lost foam casting is a near-net forming process, suitable for the production of more precise castings of various sizes with complex structures and unlimited alloys, especially for large and thick-wall castings.

During lost foam casting process, the sand is not bonded and a foam pattern is used to form the shape of the desired metal parts. The foam pattern is “invested” into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and sapes are supported.

▶ Raw Materials Available for Lost Foam Casting (LFC):

• Aluminium Alloys.

• Carbon Steel: Low carbon, medium carbon and high carbon steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Lost Foam Casting

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

▶ Main Production Procedure

• Mold foam pattern making.

• Age pattern to allow dimensional shrinkage.

• Assemble pattern into a tree

• Build cluster (multiple patterns per cluster).

• Coat cluster.

• Foam pattern coating.

• Compact cluster in flask.

• Pour molten metal.

• Extract cluster from flasks.

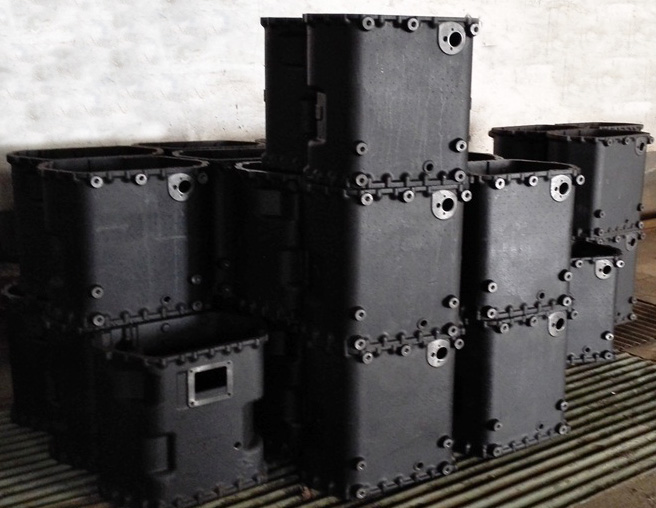

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of High Quality Gray Iron Lost Foam Casting - Custom Lost Foam Casting Factory – RMC Foundry, The product will supply to all over the world, such as: Thailand , Costa rica , Armenia , With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

-

Leading Manufacturer for Gray Iron Shell Castin...

-

Chinese Professional Stainless Steel Investment...

-

Short Lead Time for Ductile Iron Casting Compan...

-

Factory Cheap Hot China Machining Products - B...

-

Leading Manufacturer for Gray Iron Shell Castin...

-

Chinese wholesale Lost Foam Casting Manufacture...