Wholesale Steel Lost Wax Casting Parts - Custom Lost Foam Casting Factory – RMC Foundry Detail:

Custom lost foam castings could be made by according to the drawings and requirements with quick production and competitive prices. Lost foam casting is a near-net forming process, suitable for the production of more precise castings of various sizes with complex structures and unlimited alloys, especially for large and thick-wall castings.

During lost foam casting process, the sand is not bonded and a foam pattern is used to form the shape of the desired metal parts. The foam pattern is “invested” into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and sapes are supported.

▶ Raw Materials Available for Lost Foam Casting (LFC):

• Aluminium Alloys.

• Carbon Steel: Low carbon, medium carbon and high carbon steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Lost Foam Casting

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

▶ Main Production Procedure

• Mold foam pattern making.

• Age pattern to allow dimensional shrinkage.

• Assemble pattern into a tree

• Build cluster (multiple patterns per cluster).

• Coat cluster.

• Foam pattern coating.

• Compact cluster in flask.

• Pour molten metal.

• Extract cluster from flasks.

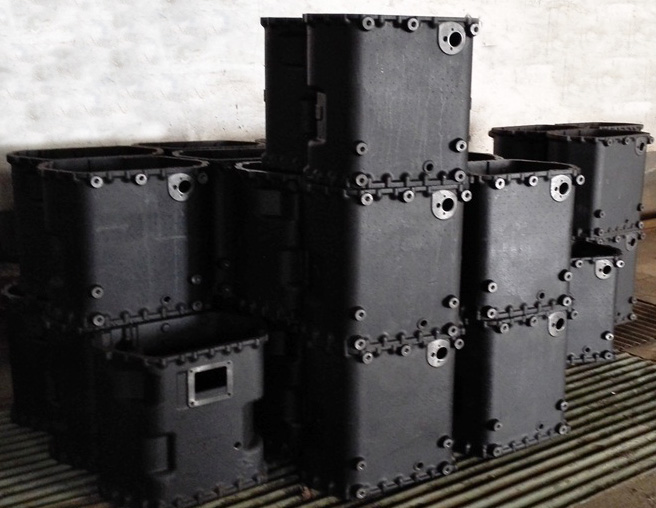

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Wholesale Steel Lost Wax Casting Parts - Custom Lost Foam Casting Factory – RMC Foundry, The product will supply to all over the world, such as: Japan , Germany , Jamaica , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

-

Special Price for Stainless Steel Lost Wax Cast...

-

Professional China Steel Lost Foam Casting - L...

-

Cheap price Malleable Iron Sand Casting Supplie...

-

Short Lead Time for Zinc Alloy Gravity Casting ...

-

2020 New Style Malleable Casting Foundry - Sta...

-

Factory Cheap Hot Investment Casting Company - ...