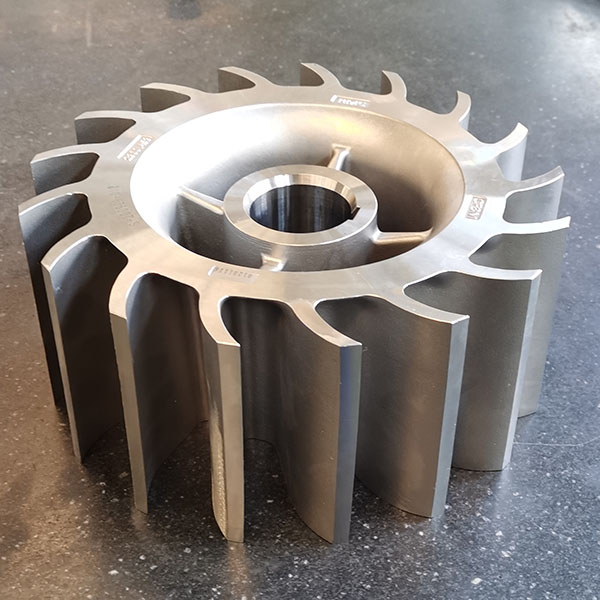

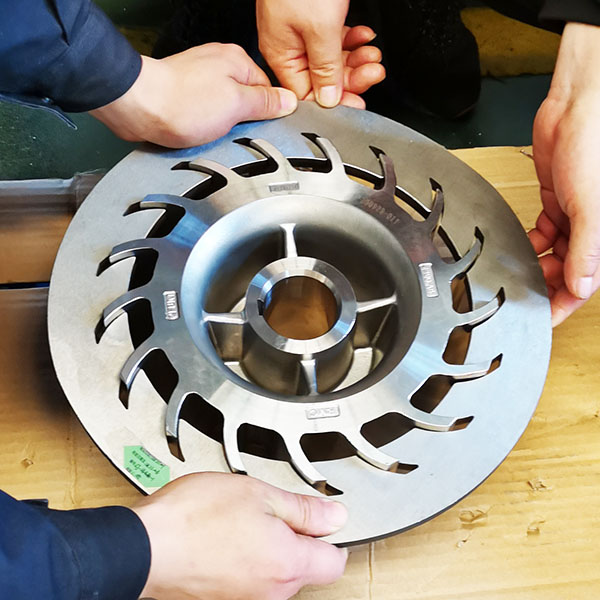

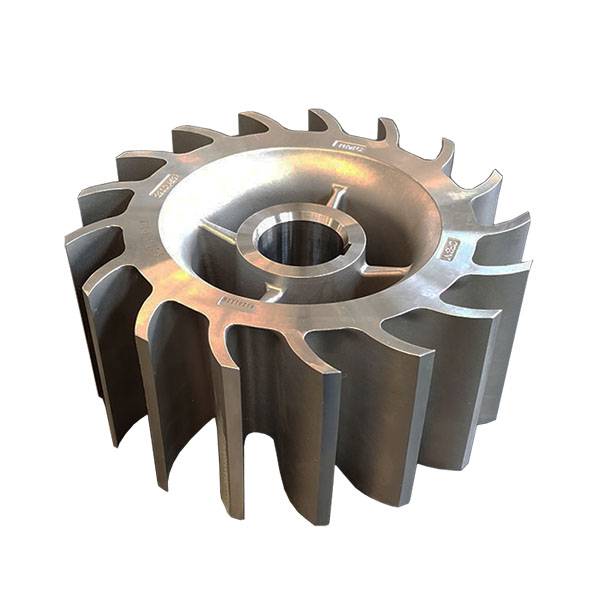

Well-designed Bronze Lost Wax Casting - CNC Machined Stainless Steel Parts – RMC Foundry Detail:

Stainless steel cast and machined impellers by investment casting and CNC precision machining processes from China casting company.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | General Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

▶ Available Machining Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for CNC Machined Parts:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Alloy steel and stainless steel from standard grades to special grades on request.

▶ Available Non-Ferrous Metal Materials for CNC Machining:

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex

• Heat-resistant Steel, Corrosion-resistant Steel and other metal with special mechanical properties.

▶ Our In-house Machining Workshop Give Our Customers the Following Advantages:

• Short lead time for machined castings and forgings.

• Only one contact for castings, forgings and machining.

• Fast transmission between foundry and machining workshop.

• Well communication inside our systems and with our customers.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

Product detail pictures:

Related Product Guide:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for Well-designed Bronze Lost Wax Casting - CNC Machined Stainless Steel Parts – RMC Foundry, The product will supply to all over the world, such as: Pretoria , St. Petersburg , Portugal , Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.

-

PriceList for No Bake Casting - Custom Brass I...

-

China Gold Supplier for Steel Shell Casting Fou...

-

Wholesale Dealers of Alloy Steel Green Sand Cas...

-

New Arrival China Duplex Stainless Steel Lost W...

-

Best quality Ductile Iron Lost Foam Casting Fou...

-

PriceList for Lost Wax Casting Parts - CNC Mac...