Professional Design Zinc Alloy Permanent Casting - Custom Cast Iron Sand Casting – RMC Foundry Detail:

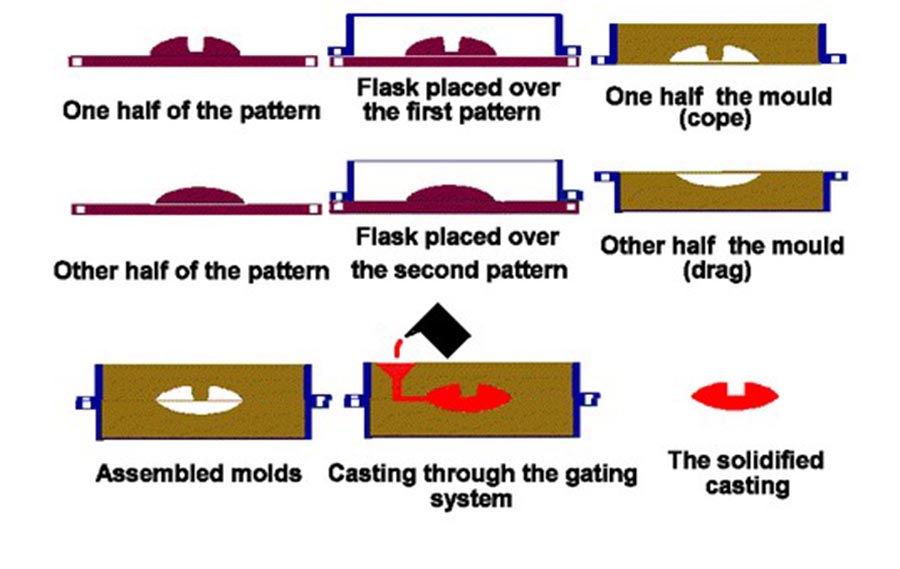

Sand casting foundry is the metal foundry mainly using sand casting process to produce metal castings made of gray iron, ductile iron, cast steel, stainless steel, brass and aluminum alloys. Sand casting process is mainly used to produce grey iron castings and ductile iron castings. It could be divided into green sand casting, furan resin pre-coated sand (shell molding) casting based on different sand materials. Cast iron sand castings have many advantages such as low costs, complex design, high effeciency, and good quality. Sand casting process is a suitable and good choice for iron casting parts unless the special or very high requirements have to be matched.

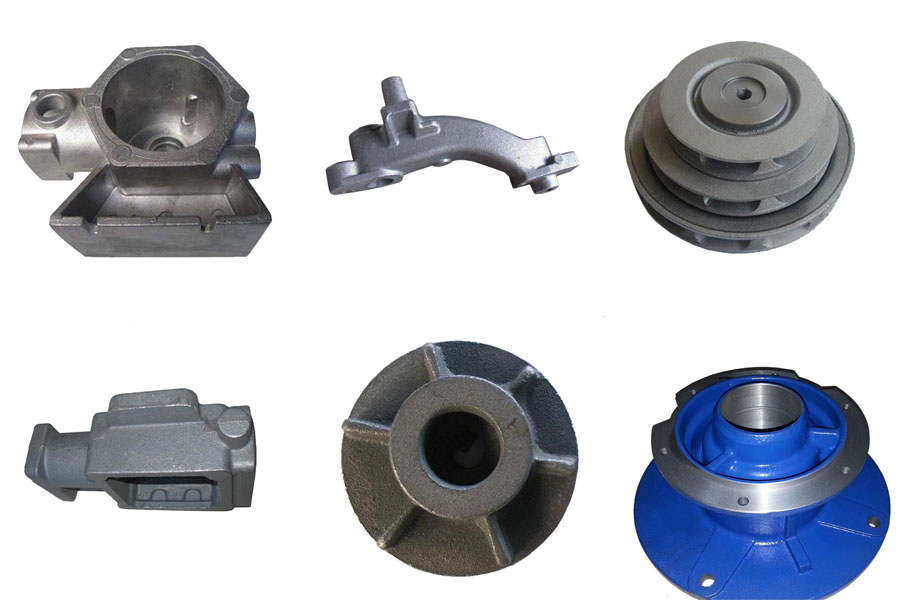

RMC Foundry can pour iron castings using our green sand mold, heat shell mold and no-bake casting process up to tons of finished weight in gray iron castings and ductile iron castings, and up to hundreds of kilograms in steel castings and stainless steel castings. RMC can produce casting parts in a wide variety of materials, including grey iron, ductile iron, stainless steel, carbon steel, wear-resistant steel, and heat-resistant steel based on different standards from China and overseas.

RMC Foundry’s experience in creating high-end sand castings from high-grade materials and consisting of complex geometries is beyond comparison. In our high-tech facilities, we offer both machine and manual molding operations in our resin sand casting processes. We produce parts in low-to-high volumes and pour castings ranging from 0.5 kg to tons. Our green sand castings range from 0.5 kgs to 800 kgs

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Professional Design Zinc Alloy Permanent Casting - Custom Cast Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Kyrgyzstan , Curacao , New Delhi , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

-

China wholesale Ductile Iron Shell Mold Casting...

-

Wholesale Dealers of Brass Foundry - Alloy Ste...

-

Factory making Ductile Iron Casting Manufacture...

-

Leading Manufacturer for Gray Iron Shell Castin...

-

Factory wholesale Stainless Steel Vacuum Castin...

-

2020 Good Quality Stainless Steel Investment Ca...