Professional China Alloy Steel Investment Casting - Stainless Steel Precision Casting Exhaust Manifold – RMC Foundry Detail:

Stainless Steel Precision Casting with OEM Custom and CNC Machining Services

Our lost wax casting foundry can manufacture custom stainless steel investment castings that match your exact design specifications. For parts ranging from tens of grams to tens of kilograms or more, we provide tight tolerances and consistent part to part repeatability.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

▶ Main Production Procedure

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ Why You Choose RMC for Custom Lost Wax Casting Parts?

• Full solution from one single supplier ranging customized pattern design to finished castings and secondary process including CNC machining, heat treatment and surface treatment.

• Costdown proposals from our professional engineers based on your unique requirement.

• Short leadtime for prototype, trial casting and any possible technical improvement.

• Bonded Materials: Silica Col, Water Glass and their mixtures.

• Manufacturing flexibility for small orders to mass orders.

• Strong outsourcing manufacturing capabilities.

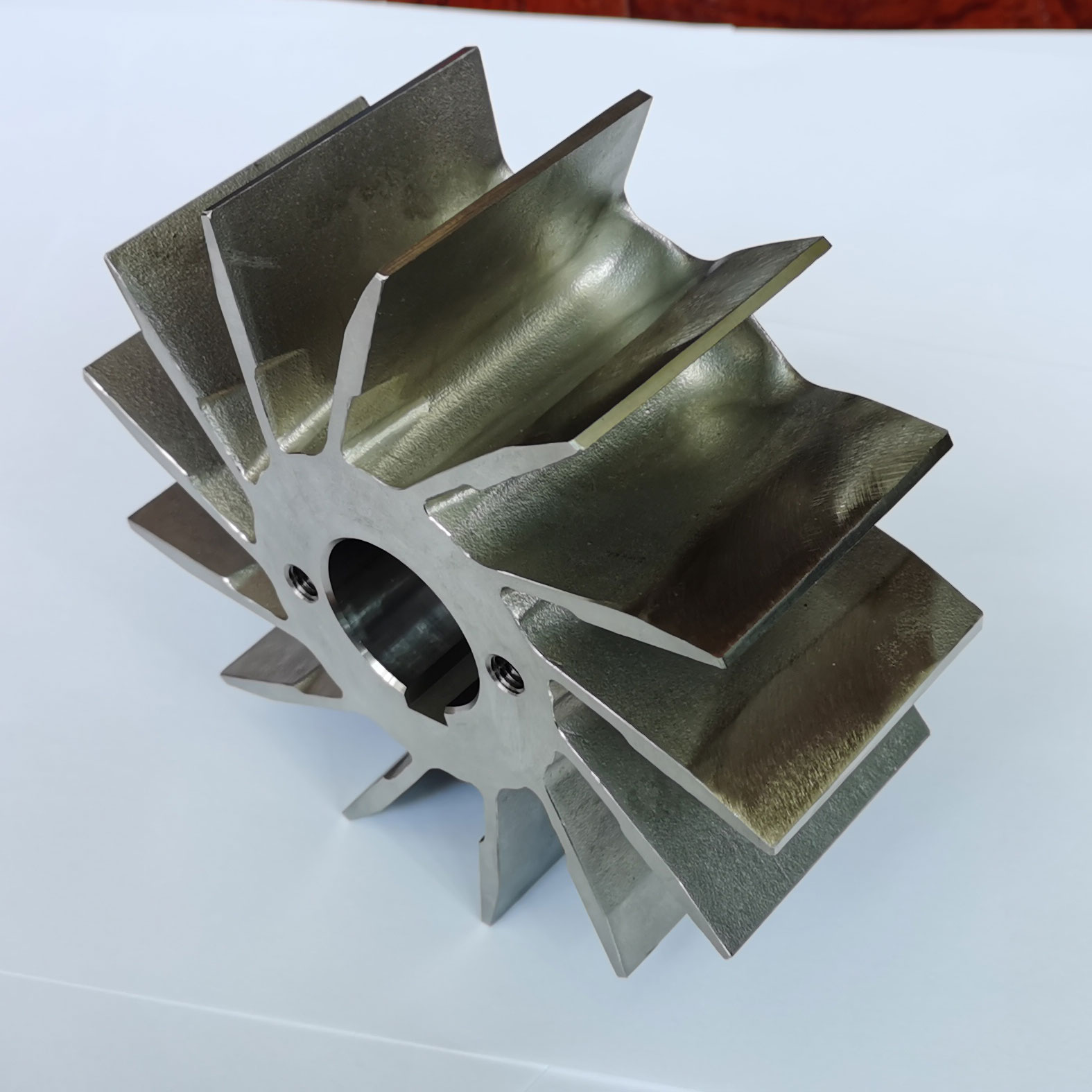

Product detail pictures:

Related Product Guide:

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for Professional China Alloy Steel Investment Casting - Stainless Steel Precision Casting Exhaust Manifold – RMC Foundry, The product will supply to all over the world, such as: Cambodia , French , Mexico , They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

Hot New Products Investment Casting Parts - Al...

-

Manufacturer of Aluminium Foundry - Duplex Sta...

-

Good quality Gravity Casting - Custom Brass In...

-

2020 High quality Shell Mold Casting Products -...

-

Chinese Professional China Cnc Machining - Cus...

-

Newly Arrival Precision Machining Services - L...