OEM/ODM China Stainless Steel Investment Casting Company - OEM Carbon Steel Precision Investment Casting Product – RMC Foundry Detail:

China OEM custom carbon steel casting products by lost wax investment casting process.

| Cast Carbon Steel Grade Comparison | |||||||||||

| No. | China | Japan | U.S.A. | ISO | Germany | France | Russia гост | Sweden SS | Britain | ||

| GB | JIS | ASTM | UNS | DIN | W-Nr. | NF | BS | ||||

| 1 | ZG200-400 (ZG15) | SC410 (SC42) | 415-205 (60-30) | J03000 | 200-400 | GS-38 | 1.0416 | - | 15л | 1306 | - |

| 2 | ZG230-450 (ZG25) | SC450 (SC46) | 450-240 965-35) | J03101 | 230-450 | GS-45 | 1.0446 | GE230 | 25л | 1305 | A1 |

| 3 | ZG270-500 (ZG35) | SC480 (SC49) | 485-275 (70-40) | J02501 | 270-480 | GS-52 | 1.0552 | GE280 | 35л | 1505 | A2 |

| 4 | ZG310-570 (ZG45) | SCC5 | (80-40) | J05002 | - | GS-60 | 1.0558 | GE320 | 45л | 1606 | - |

| 5 | ZG340-640 (ZG55) | - | - | J05000 | 340-550 | - | - | GE370 | - | - | A5 |

Capabilities of Investment Casting Foundry:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

Advantages of Investment Casting Components:

- Excellent and smooth surface finish

- Tight dimensional tolerances.

- Complex and intricate shapes with design flexibility

- Capability to cast thin walls therefore a lighter casting component

- Wide selection of cast metals and alloys (ferrous and non-ferrous)

- Draft is not required in the molds design.

- Reduce the need for secondary machining.

- Low material waste.

| Materials for Investment Casting Process at RMC Foundry | |||

| Category | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless steel | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 |

302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 |

1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Steel | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo |

309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35-1, INCOLOY600, INCOLOY625 |

2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy |

ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 |

C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Millimeters | ||

| Dimension | Tolerance | Dimension | Tolerance |

| Up to 0.500 | ±.004″ | Up to 12.0 | ± 0.10mm |

| 0.500 to 1.000” | ±.006″ | 12.0 to 25.0 | ± 0.15mm |

| 1.000 to 1.500” | ±.008″ | 25.0 to 37.0 | ± 0.20mm |

| 1.500 to 2.000” | ±.010″ | 37.0 to 50.0 | ± 0.25mm |

| 2.000 to 2.500” | ±.012″ | 50.0 to 62.0 | ± 0.30mm |

| 2.500 to 3.500” | ±.014″ | 62.0 to 87.0 | ± 0.35mm |

| 3.500 to 5.000” | ±.017″ | 87.0 to 125.0 | ± 0.40mm |

| 5.000 to 7.500” | ±.020″ | 125.0 to190.0 | ± 0.50mm |

| 7.500 to 10.000” | ±.022″ | 190.0 to 250.0 | ± 0.57mm |

| 10.000 to 12.500” | ±.025″ | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028″ | 312.0 to 375.0 | ± 0.70mm |

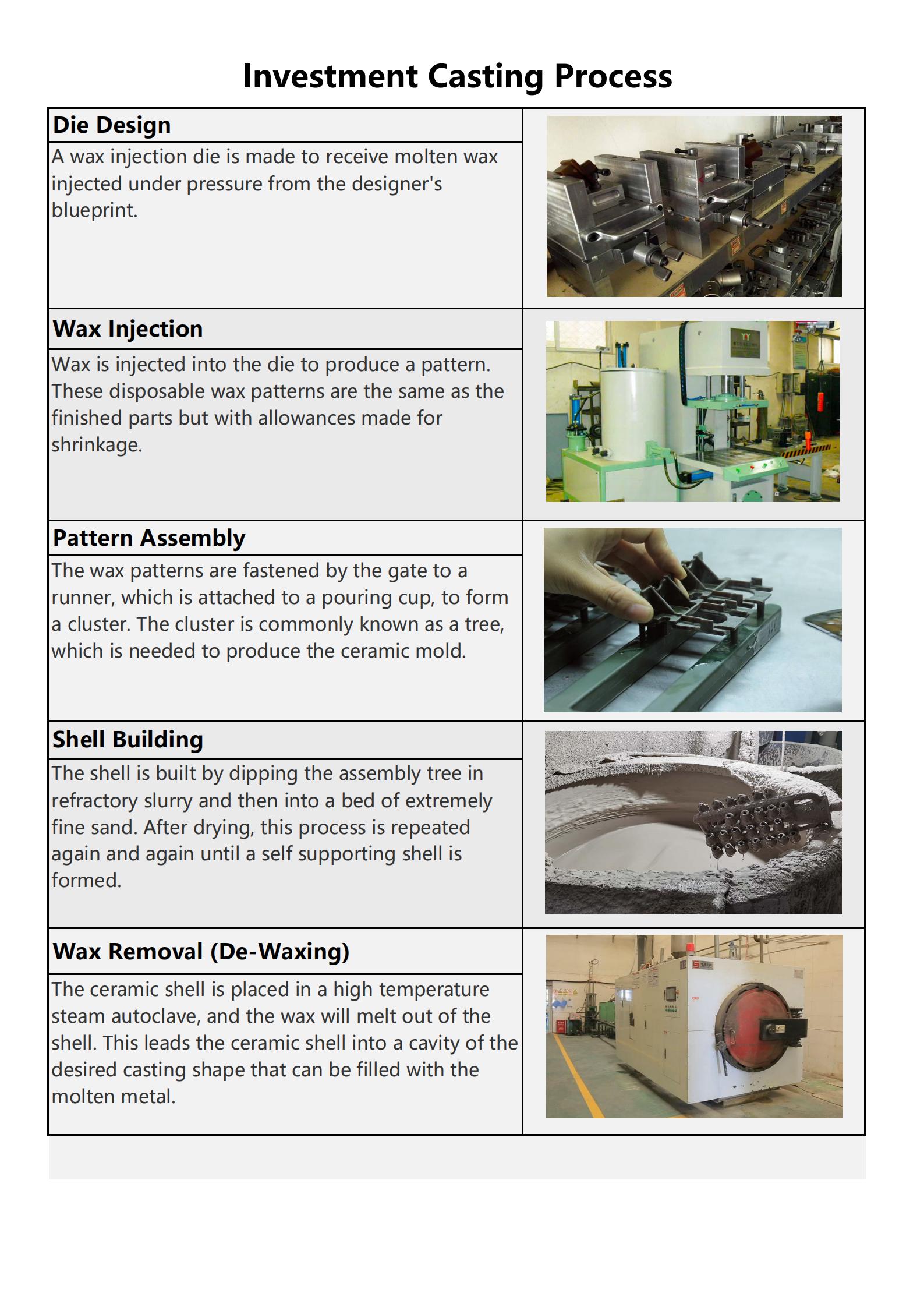

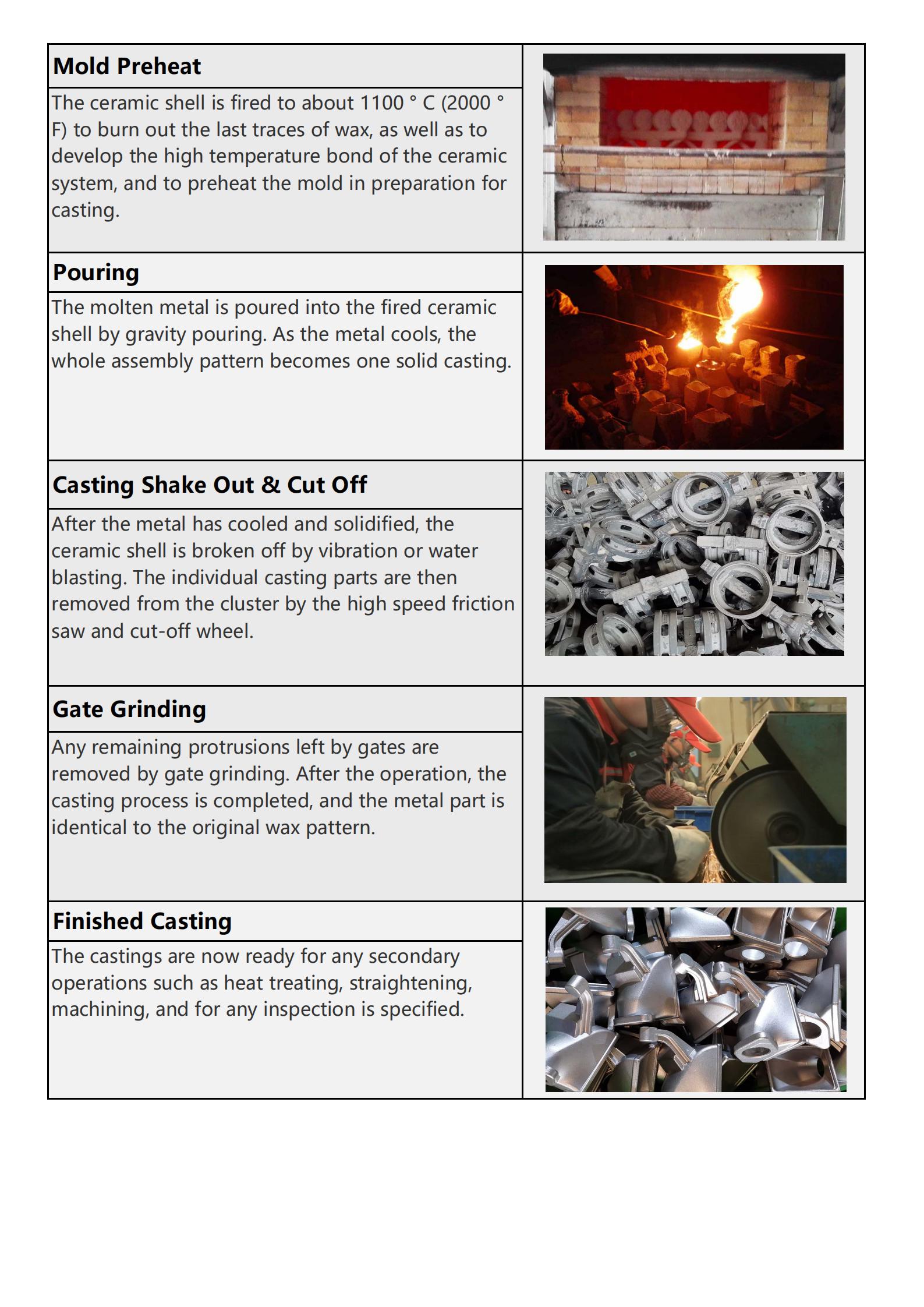

Carbon Steel Castings by Investment Casting

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM/ODM China Stainless Steel Investment Casting Company - OEM Carbon Steel Precision Investment Casting Product – RMC Foundry, The product will supply to all over the world, such as: Bolivia , French , St. Petersburg , Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

-

Reasonable price Solid Mold Casting - Custom A...

-

Hot sale Full Mold Casting - Ductile Cast Iron...

-

Factory Cheap Hot China Machining Products - C...

-

2020 wholesale price Alloy Steel Investment Cas...

-

Wholesale Price China China Machining Factory -...

-

Good Quality Stainless Steel Precision Casting ...