Manufactur standard Alloy Steel Foundry - Lost Foam Casting Aluminium Company – RMC Foundry Detail:

Lost foam casting aluminium parts are widely used for transmission cover of heavy duty truck. During lost foam casting process, the sand is not bonded and a foam pattern is used to form the shape of the desired metal parts. The foam pattern is “invested” into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and sapes are supported.

Lost Foam Casting, also called EPC (Expandable Pattern Casting) or LFC (Lost Foam Casting), is to put the foamed plastic pattern group coated with refractory coating into the sand box, and fill it with dry sand or self-hardening sand around the pattern. During pouring, the high-temperature molten metal makes the foam pattern pyrolyzed and “disappears” and occupies the exit space of the pattern, and finally the casting method of the casting is obtained.

The castings produced by lost foam casting have high dimensional accuracy and smooth surface with less pollution in the production process. Lost foam casting is a near-net forming process, suitable for the production of more precise castings of various sizes with complex structures and unlimited alloys.

▶ Raw Materials Available for Lost Foam Casting (LFC):

• Aluminium Alloys.

• Carbon Steel: Low carbon, medium carbon and high carbon steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Lost Foam Casting Aluminium Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

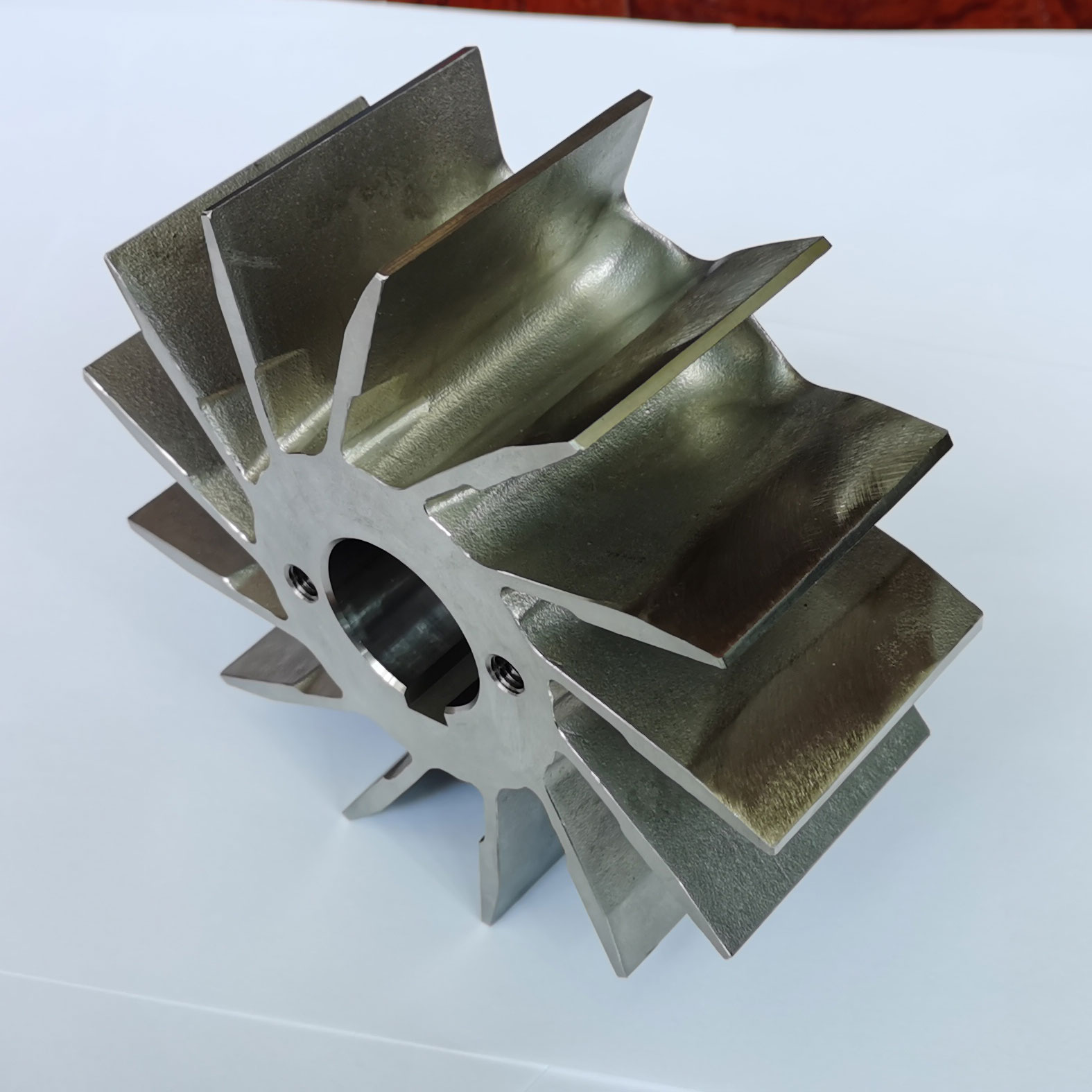

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Manufactur standard Alloy Steel Foundry - Lost Foam Casting Aluminium Company – RMC Foundry, The product will supply to all over the world, such as: Leicester , Tanzania , Kenya , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

High Quality Precision Casting - Duplex Stainl...

-

Good User Reputation for Machining Services - ...

-

China Cheap price Shell Mold Casting Parts - C...

-

2020 China New Design Alloy Steel Shell Mold Ca...

-

Factory Outlets Stainless Steel Casting Foundry...

-

Fast delivery Nodular Iron Casting - Ductile C...