Factory wholesale No Bake Molding Casting - Precipitation Hardening Stainless Steel Casting – RMC Foundry Detail:

OEM custom investment casting products made of precipitation hardening stainless steel from China foundry.

Precipitation hardening stainless steel refers to the kind of stainless steel which adds different types and quantities of strengthening elements, and different types and quantities of carbides, nitrides, carbonitrides and intermetallic compounds are precipitated through the precipitation hardening process. Precipitation hardening stainless steel not only has high strength, but also has good toughness and corrosion resistance. For precipitation hardening steel castings containing copper, the hardness of the steel castings is increased due to the precipitation of hard copper-rich phases in the as-cast state during the cooling process. In order to soften the structure and improve the processing performance, such steel castings require solution heat treatment. The solid solution temperature of precipitation hardening steel castings containing copper is generally 900 ℃ ~ 950 ℃. After cooling, a supersaturated single-phase structure with a copper mass fraction of 1.0% ~ 1.5% can be obtained.

Precipitation hardening stainless steel is widely used in advanced industries. For example, the typical precipitation hardening stainless steel 17-4PH can be used to make structures below 370°C that require corrosion resistance, wear resistance, and high strength.

RMC Foundry Cast the Following Typical Grades of Precipitation Hardening Stainless Steel

1- Chinese standards: 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb

2- British Standard: ANC20, ANC21, ANC22

3- American standards: 630, 634, 17-4PH, 15-5PH, CB7Cu-1

4- Japanese standards: SCS24, SCS32

5- German Standard: 1.4542

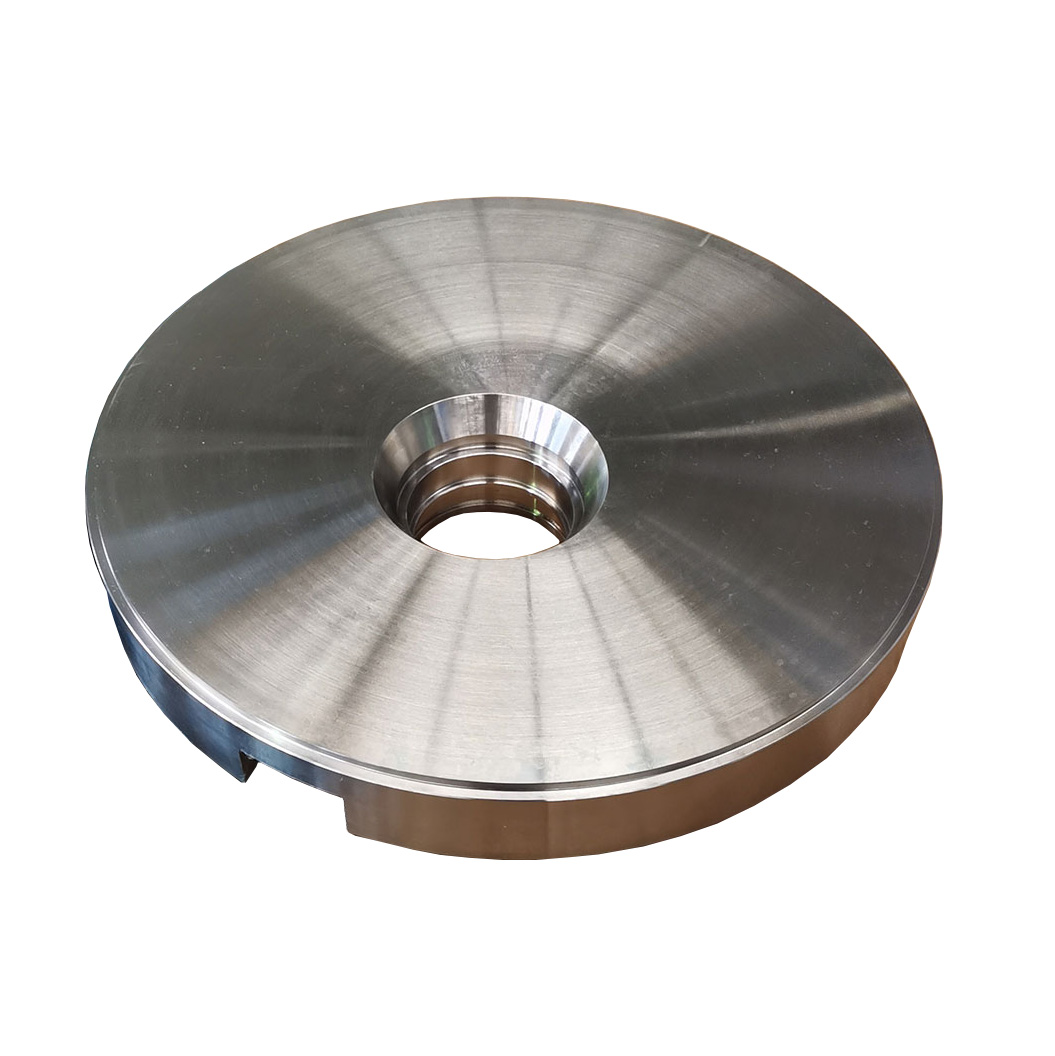

Product detail pictures:

Related Product Guide:

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for Factory wholesale No Bake Molding Casting - Precipitation Hardening Stainless Steel Casting – RMC Foundry, The product will supply to all over the world, such as: Berlin, Singapore, Uruguay, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

We have been looking for a professional and responsible supplier, and now we find it.

-

2020 New Style Bronze Green Sand Casting - Duc...

-

OEM/ODM China Malleable Iron Sand Casting Found...

-

Good quality Gravity Casting - Alloy Steel Pre...

-

Cheap price Nodular Iron No Bake Casting - Bra...

-

Best Price on Duplex Stainless Steel Green Sand...

-

New Fashion Design for Brass Sand Casting - Va...