Factory Outlets Zinc Alloy Sand Casting - Custom Cast Iron Sand Casting – RMC Foundry Detail:

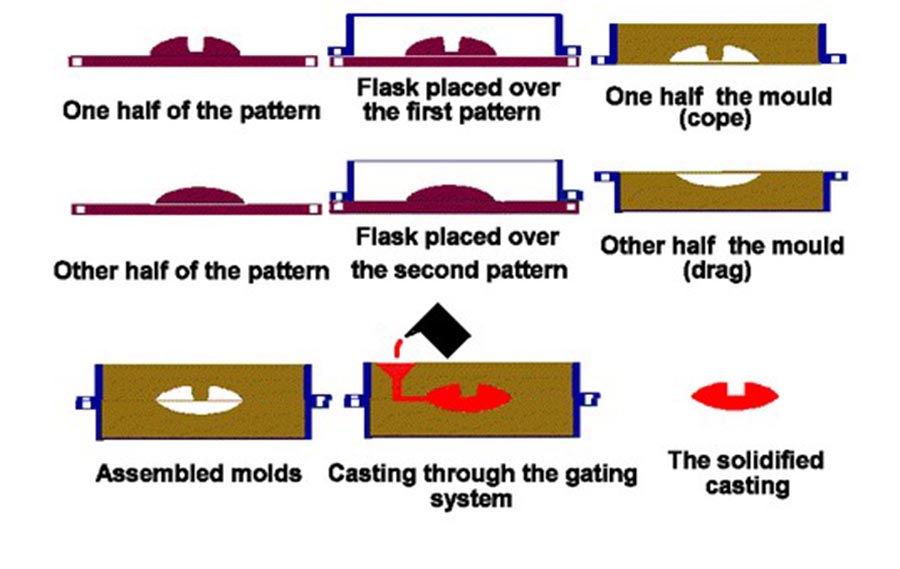

Sand casting foundry is the metal foundry mainly using sand casting process to produce metal castings made of gray iron, ductile iron, cast steel, stainless steel, brass and aluminum alloys. Sand casting process is mainly used to produce grey iron castings and ductile iron castings. It could be divided into green sand casting, furan resin pre-coated sand (shell molding) casting based on different sand materials. Cast iron sand castings have many advantages such as low costs, complex design, high effeciency, and good quality. Sand casting process is a suitable and good choice for iron casting parts unless the special or very high requirements have to be matched.

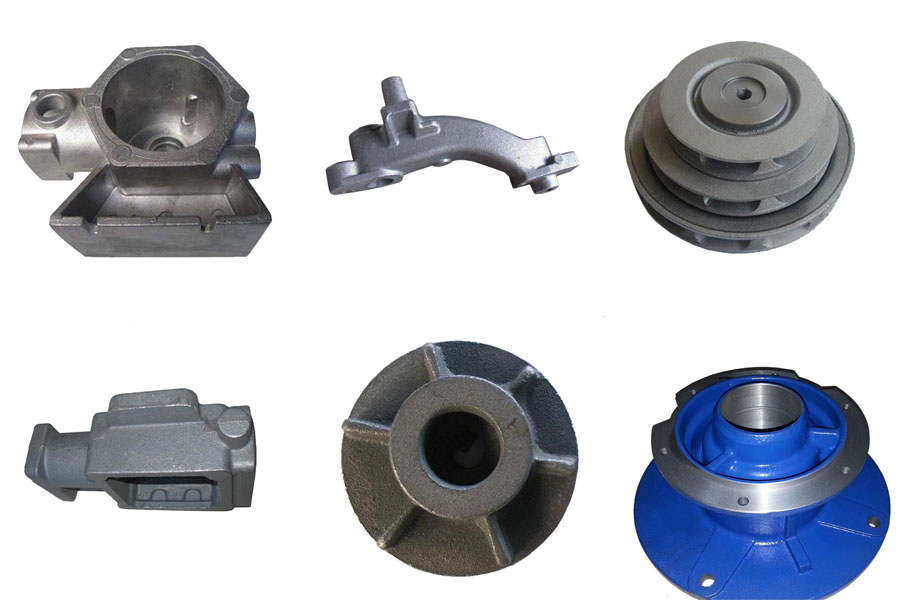

RMC Foundry can pour iron castings using our green sand mold, heat shell mold and no-bake casting process up to tons of finished weight in gray iron castings and ductile iron castings, and up to hundreds of kilograms in steel castings and stainless steel castings. RMC can produce casting parts in a wide variety of materials, including grey iron, ductile iron, stainless steel, carbon steel, wear-resistant steel, and heat-resistant steel based on different standards from China and overseas.

RMC Foundry’s experience in creating high-end sand castings from high-grade materials and consisting of complex geometries is beyond comparison. In our high-tech facilities, we offer both machine and manual molding operations in our resin sand casting processes. We produce parts in low-to-high volumes and pour castings ranging from 0.5 kg to tons. Our green sand castings range from 0.5 kgs to 800 kgs

Product detail pictures:

Related Product Guide:

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for Factory Outlets Zinc Alloy Sand Casting - Custom Cast Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Croatia , India , America , Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

New Fashion Design for Brass Gravity Casting - ...

-

High reputation Malleable Iron Sand Casting Fac...

-

Factory Cheap Hot Gray Iron Sand Casting Foundr...

-

Professional China Steel Lost Foam Casting - L...

-

Factory wholesale Ductile Iron Casting Parts - ...

-

China Factory for Brass Sand Casting Foundry - ...