Malleable Iron Casting Foundry – Stainless Steel CNC Precision Machining – RMC Foundry Detail:

Stainless Steel CNC Precision Machining parts from China Machining Company.

State-of-the-art vertical and horizontal CNC machining centers and other CNC machines could make sure the accuracy of the castings and guarantee the machined castings are finished on time. All machines are well-organized and taken into production at high production effeciency and good cost-effective mothods. If needed, all the machined dimensions could be measured by the CMM and the related reports could be issued as per customer’s requirements.

▶ Equipment for Precision Machining Components:

• Convertional Machining Machines: 20 sets.

• CNC Machines: 60 sets.

• 3-Axis Machining Center: 10 sets.

• 4-Axis Machining Center: 5 sets.

• 5-Axis Machining Center: 2 sets

▶ Precision Machining Capabilities

• Max Size: 1,500 mm × 800 mm × 500 mm

• Weight Range: 0.1 kg – 500 kg

• Annual Capacity: 10,000 tons

• Accuracy: As per standards: …. or on request. Minimum ±0.003 mm

• Holes to ±0.002 mm dia.

• Flatness, Roundness and Straightness: As per standards or on request.

▶ Available Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for Precision Machining Components:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Steel Alloys from standard grades to special grades on request.

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex, Corrosion-resistant Steel, High-temperature Steel.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

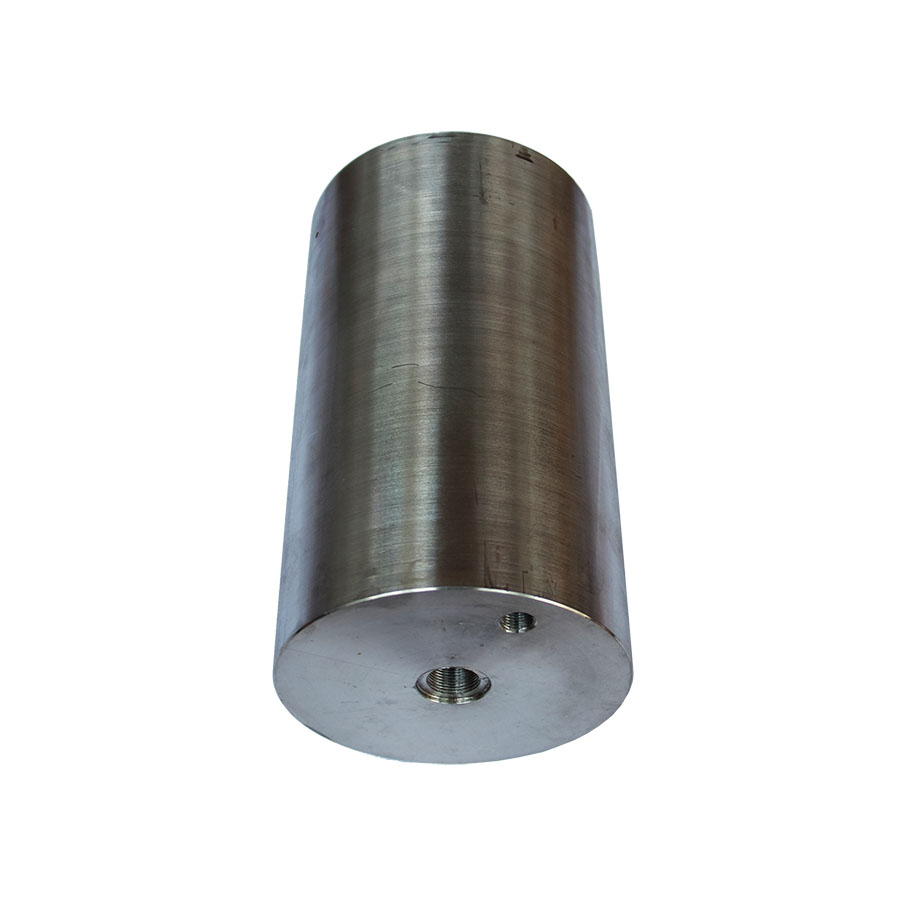

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for Malleable Iron Casting Foundry – Stainless Steel CNC Precision Machining – RMC Foundry, The product will supply to all over the world, such as: Saudi Arabia , Hamburg , Mali , Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

-

High reputation Alloy Steel Lost Wax Casting Pr...

-

Top Suppliers Furan Resin Sand Casting - Wear ...

-

Cheap price Alloy Steel Precision Casting Produ...

-

Bottom price Steel Precision Casting Products -...

-

100% Original Factory Gray Iron Casting Manufac...

-

Factory source Carbon Steel No Bake Casting - ...