Factory Cheap Hot Investment Casting Company - Custom Duplex Stainless Steel CD3MWCuN Investment Casting Product – RMC Foundry Detail:

Custom cast duplex stainless steel investment casting product from China casting manufacturer with machining, heat treatment, and surface treatment services.

RMC metal casting manufactures precision cast metal parts that consistently meet or exceed customer expectations. Lost wax investment casting allows us to produce metal parts as small as tens of grams and as large as tens of kilograms, in a wide range of ferrous and non-ferrous alloys and with exceptional dimensional accuracy.

The lost wax casting process produces near-net-shape precision metal parts that often require little or no additional machining. The resulting finish is also much better than what is achievable through other processes. The strength and durability of the casting parts make themselves ideal for high wear-resistance applications requiring millions of cycles.

Duplex Stainless Steel (DSS) refers to stainless steel with ferrite and austenite each accounting for about 50%. Generally, the content of less phases needs to be at least 30%. In the case of low C content, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some duplex stainless steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

Available grade of duplex stainless steel at RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

The DSS has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and ductility, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining brittleness, high thermal conductivity, and superplasticity as ferrite stainless steel. Compared with austenitic stainless steel, DSS has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

▶ Ferrous Metals and Non-ferrous Metals for Investment Casting, Lost Wax Casting Process:

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 – AISI 1060, C30, C40, C45.

• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 and other stainless steel grade.

• Brass, Red Copper, Bronze or other Copper-based alloy metals: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Other Materials as per your unique requirements or according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards

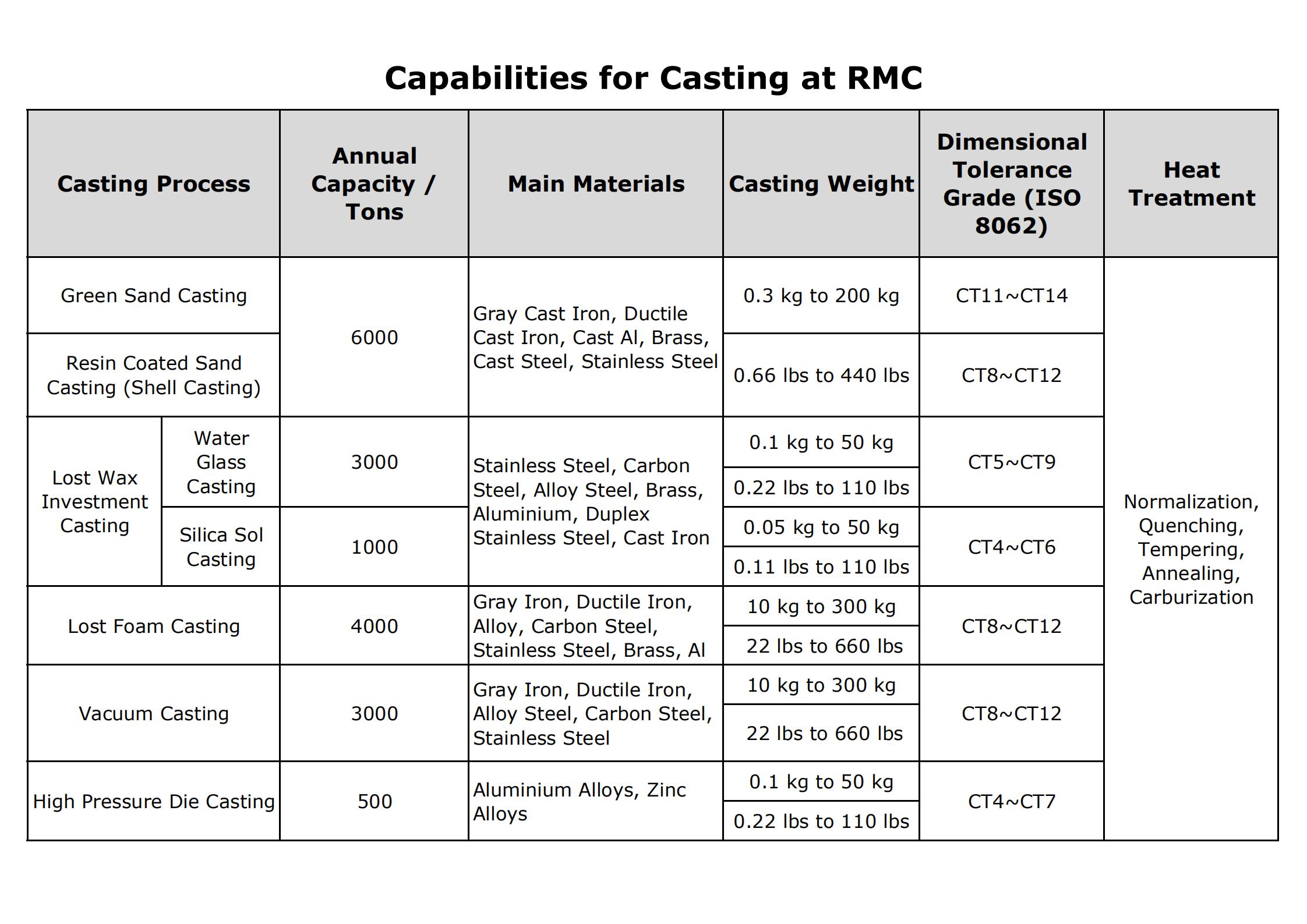

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Factory Cheap Hot Investment Casting Company - Custom Duplex Stainless Steel CD3MWCuN Investment Casting Product – RMC Foundry, The product will supply to all over the world, such as: kazan , Florence , Honduras , What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

Cheapest Price Duplex Stainless Steel Sand Cast...

-

Cheapest Price Duplex Stainless Steel Sand Cast...

-

New Arrival China Steel Vacuum Casting - Alloy...

-

Hot New Products Machining Factory - Lost Wax ...

-

Factory best selling Steel Precision Casting Ma...

-

OEM/ODM China Stainless Steel Shell Mold Castin...