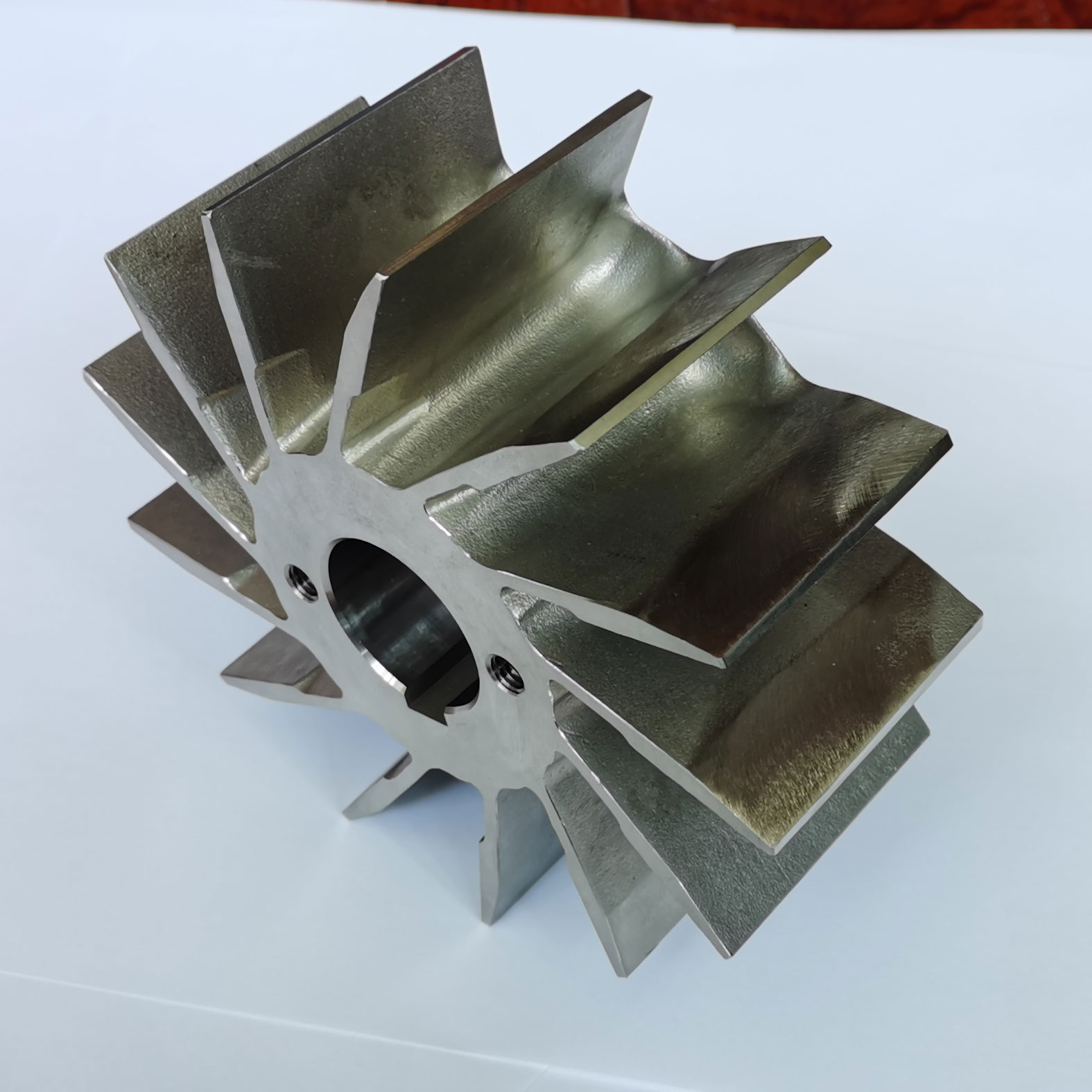

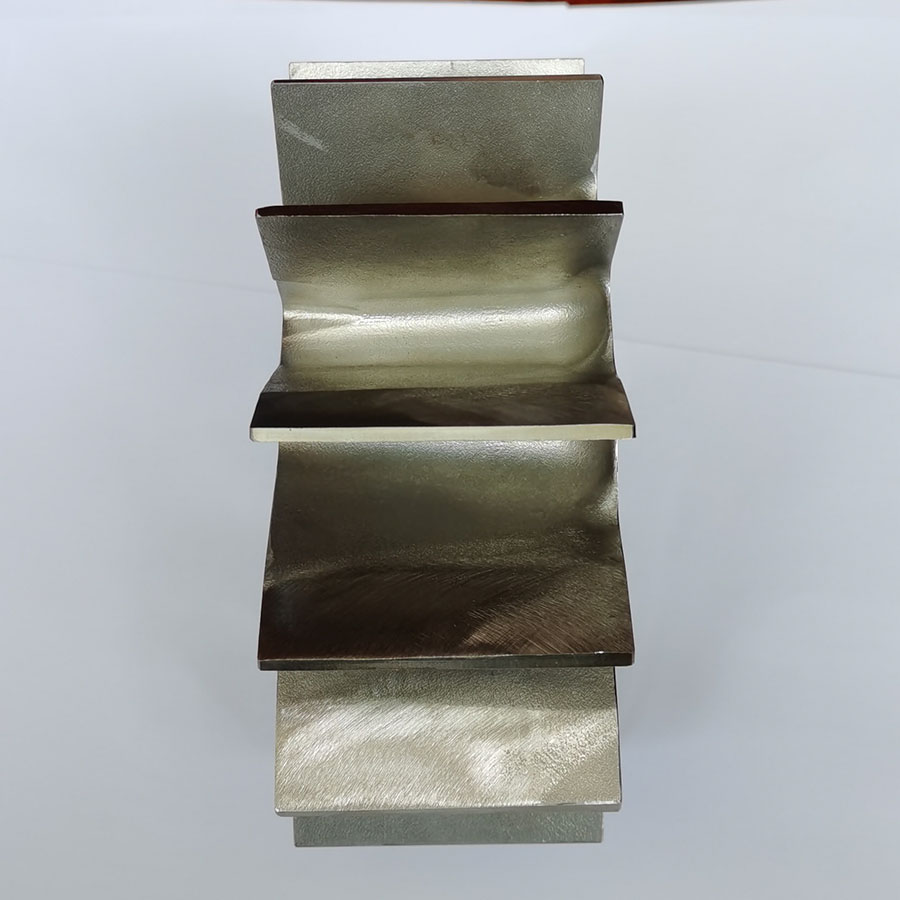

Chinese Professional China Cnc Machining - Duplex Stainless Steel Open Impeller by Investment Casting and CNC Machining – RMC Foundry Detail:

2205 duplex stainless steel is a duplex stainless steel composed of 21% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. The ferrite and austenite structures each account for approximately 50%. It has high strength, good impact toughness and good overall and local stress corrosion resistance. The yield strength of 2205 duplex stainless steel is twice that of austenitic stainless steel. This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L. This alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.

Compared with 316L and 317L austenitic stainless steel, 2205 duplex stainless steel has superior performance in resistance to pitting corrosion and crevice corrosion. It has high corrosion resistance. Compared with austenitic, its The coefficient of thermal expansion is lower and the thermal conductivity is higher. Compared with austenitic stainless steel, duplex stainless steel 2205 alloy has twice its compressive strength. Compared with 316L and 317L, the designer can reduce its weight. Alloy 2205 is especially suitable for the temperature range of -50°F/+600°F. Under strict restrictions (especially for welded structures), it can also be used at lower temperatures.

Duplex stainless steel casting means the castings made of duplex stainless steel. Duplex Stainless Steel (DSS) refers to stainless steel with ferrite and austenite each accounting for about 50%. Generally, the content of less phases needs to be at least 30%. In the case of low C content, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some duplex stainless steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

The DSS has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and ductility, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining brittleness, high thermal conductivity, and superplasticity as ferrite stainless steel. Compared with austenitic stainless steel, DSS has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

In casting production, most of the stainless steel castings are completed by investment casting. The surface of stainless steel castings produced by investment casting is smoother and the dimensional accuracy is easier to control. Of course, the cost of investment casting stainless steel parts is relatively high compared to other processes and materials.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

▶ Main Production Procedure of Investment Casting

• Create a wax pattern or replica

• Sprue the wax pattern

• Invest the wax pattern

• Eliminate the wax pattern by burning it (inside the furnace or in hot water) to create a mould.

• Force molten metal pour into the mould

• Cooling and Solidification

• Remove sprue from the castings

• Finish and polish the finished investment castings

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Chinese Professional China Cnc Machining - Duplex Stainless Steel Open Impeller by Investment Casting and CNC Machining – RMC Foundry, The product will supply to all over the world, such as: Kazakhstan , Croatia , Armenia , Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Wholesale Price Ductile Iron Shell Mold Casting...

-

Professional China Alloy Steel Investment Casti...

-

High Quality Steel Investment Casting - Grey I...

-

Factory Outlets Stainless Steel Casting Foundry...

-

Wholesale Price Carbon Steel Vacuum Casting - ...

-

OEM/ODM China Stainless Steel Shell Mold Castin...