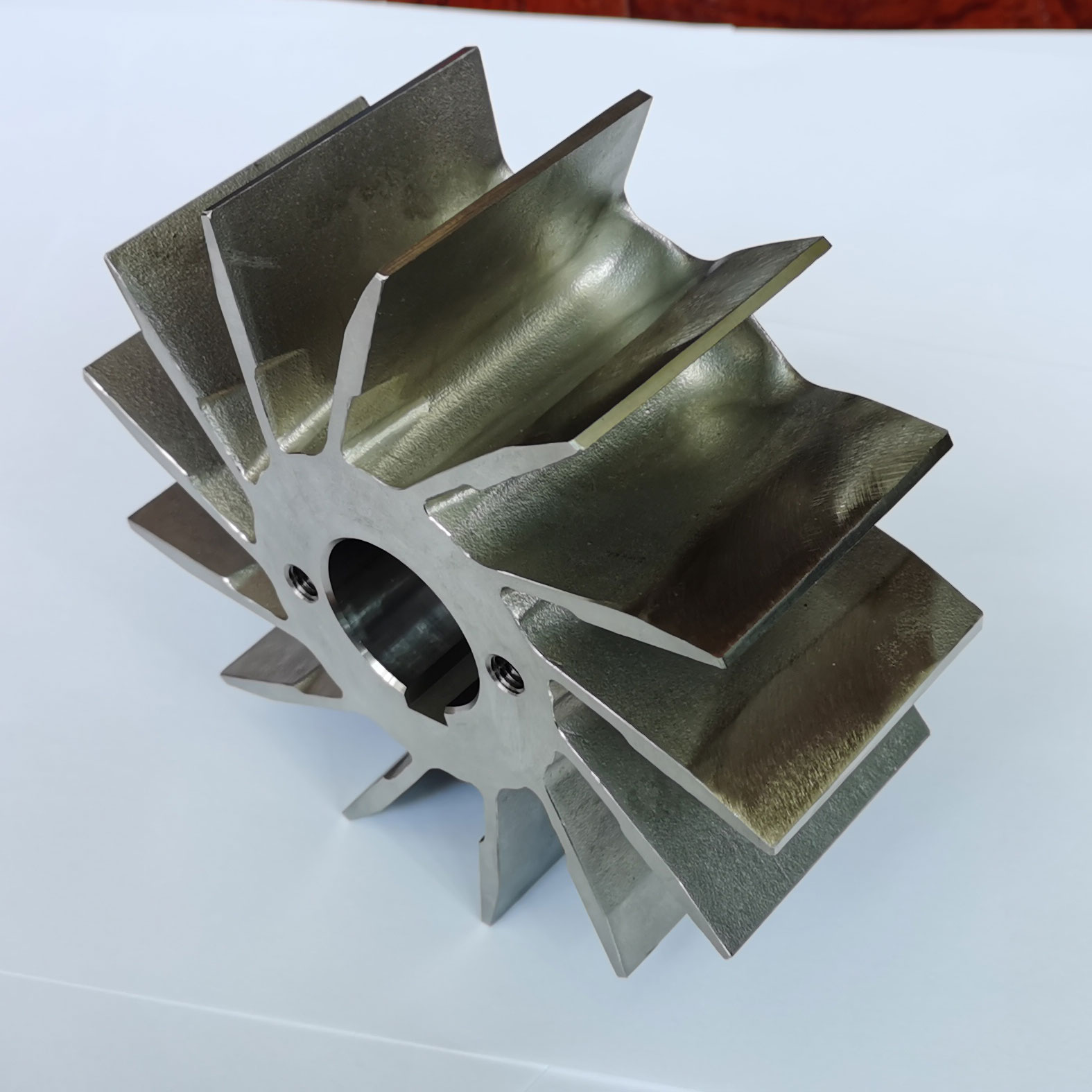

Cheap PriceList for Pre-Coated Sand Casting - Ductile Iron Sand Casting – RMC Foundry Detail:

Cast Ductile Iron Sand Casting from China Foundry with OEM Custom and CNC Machining Services.

Cast iron is an iron-carbon cast alloy with other elements that is made by remelting pig iron, scrap, and other additions. For differentiation from steel and cast steel, cast iron is defined as a cast alloy with a carbon content (min 2.03%) that ensures the solidification of the final phase with a eutectic transformation.

Depending on chemical specifications, cast irons can be non- alloyed or alloyed. The range of alloyed irons is much wider, and they contain either higher amounts of common components, such as silicon and manganese, or special additions, such as nickel, chromium, aluminum, molybdenum, tungsten, copper, vana- dium, titanium, plus others. Generally speaking, the cast iron could be divided into gray iron, ducitle iron (nodular iron), white cast iron, compacted graphite iron and malleable cast iron.

Raw Materials Available for Sand Casting

• Gray Iron: GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350

• Ductile Iron: GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2

• Aluminium and Their Alloys

• Other Materials and Standards on request

Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 5,000 tons – 6,000 tons

• Tolerances: On Request.

Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 8,000 tons – 10,000 tons

• Tolerances: On Request.

Main Production Procedure

Patterns & Tooling Design → Making Patterns → Moulding Process → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

Sand Casting Inspection Capabilities

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

General Commerial Terms

• Main work flow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Lead time: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

Product detail pictures:

Related Product Guide:

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Cheap PriceList for Pre-Coated Sand Casting - Ductile Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Borussia Dortmund, Mauritius, US, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Cheapest Price Duplex Stainless Steel Sand Cast...

-

New Arrival China Sand Casting Company - Custo...

-

PriceList for Steel Foundry - Custom Cast Iron...

-

Hot sale Factory Alloy Steel Casting Manufactur...

-

Wholesale Discount Stainless Steel Casting Supp...

-

Reliable Supplier Precision Casting Supplier -...