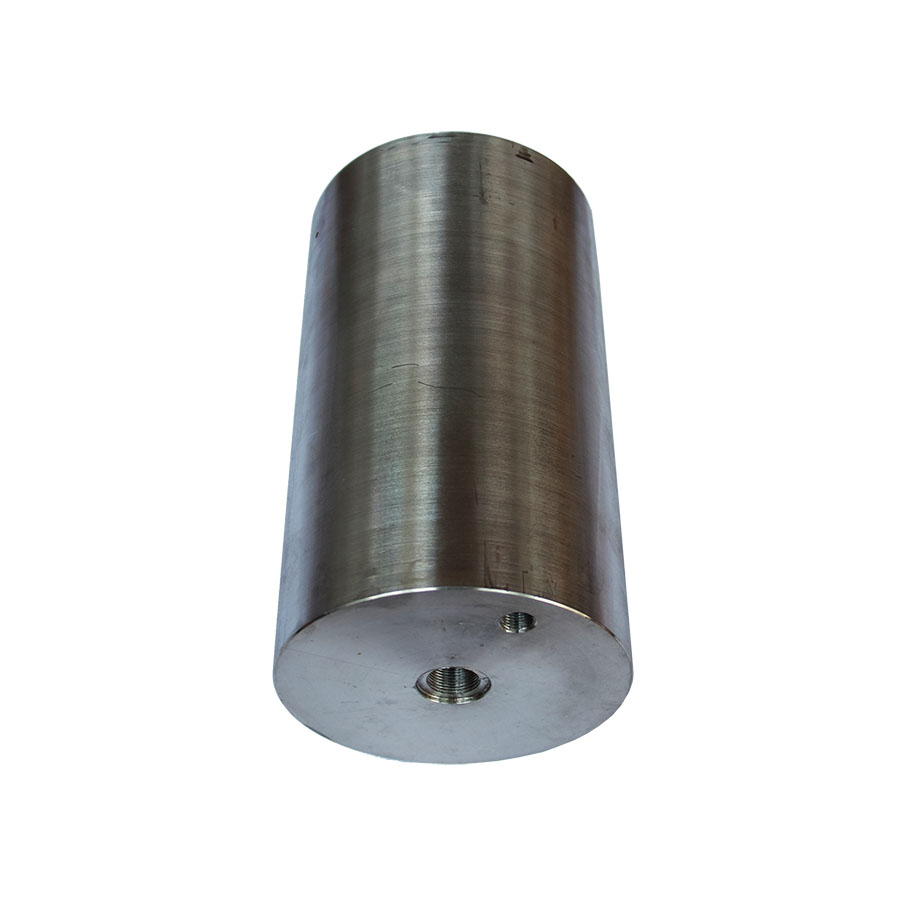

Best-Selling Precision Casting Factory - Lost Wax Casting Stainless Steel – RMC Foundry Detail:

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. The stainless steel casting has highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or “moly”). These three components will determine the casting’s grain structure and mechanical properties and will be instrumental in the casting’s ability to combat heat, wear, and corrosion.

Our investment foundry can manufacture custom stainless steel investment castings that match your exact design specifications. For parts ranging from tens of grams to tens of kilograms or more, we provide tight tolerances and consistent part to part repeatability.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

▶ Main Production Procedure of Lost Wax Casting

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ Inspecting Lost Wax Castings

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Best-Selling Precision Casting Factory - Lost Wax Casting Stainless Steel – RMC Foundry, The product will supply to all over the world, such as: Greenland, Paraguay, Dominica, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Make sure you your inquiry for more details or request for dealership in selected regions.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.