Best quality Steel Investment Casting Supplier - Stainless Steel Lost Wax Casting Product – RMC Foundry Detail:

Cast stainless steel lost wax casting products from China casting manufacturer with machining, heat treatment, and surface treatment services.

Stainless steel is often divided into martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, austenitic-ferritic (duplex) stainless steel and precipitation hardening stainless steel according to the state of microstructure. In addition, according to the chemical compositions, it can be divided into chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel, etc.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. It is highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

RMC metal casting manufactures precision cast metal parts that consistently meet or exceed customer expectations. Lost wax investment casting allows us to produce metal parts as small as tens of grams and as large as tens of kilograms, in a wide range of ferrous and non-ferrous alloys and with exceptional dimensional accuracy.

The lost wax casting process produces near-net-shape precision metal parts that often require little or no additional machining. The resulting finish is also much better than what is achievable through other processes. The strength and durability of the casting parts make themselves ideal for high wear-resistance applications requiring millions of cycles.

▶ Ferrous Metals and Non-ferrous Metals for Investment Casting, Lost Wax Casting Process:

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 – AISI 1060, C30, C40, C45.

• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 and other stainless steel grade.

• Brass, Red Copper, Bronze or other Copper-based alloy metals: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Other Materials as per your unique requirements or according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards

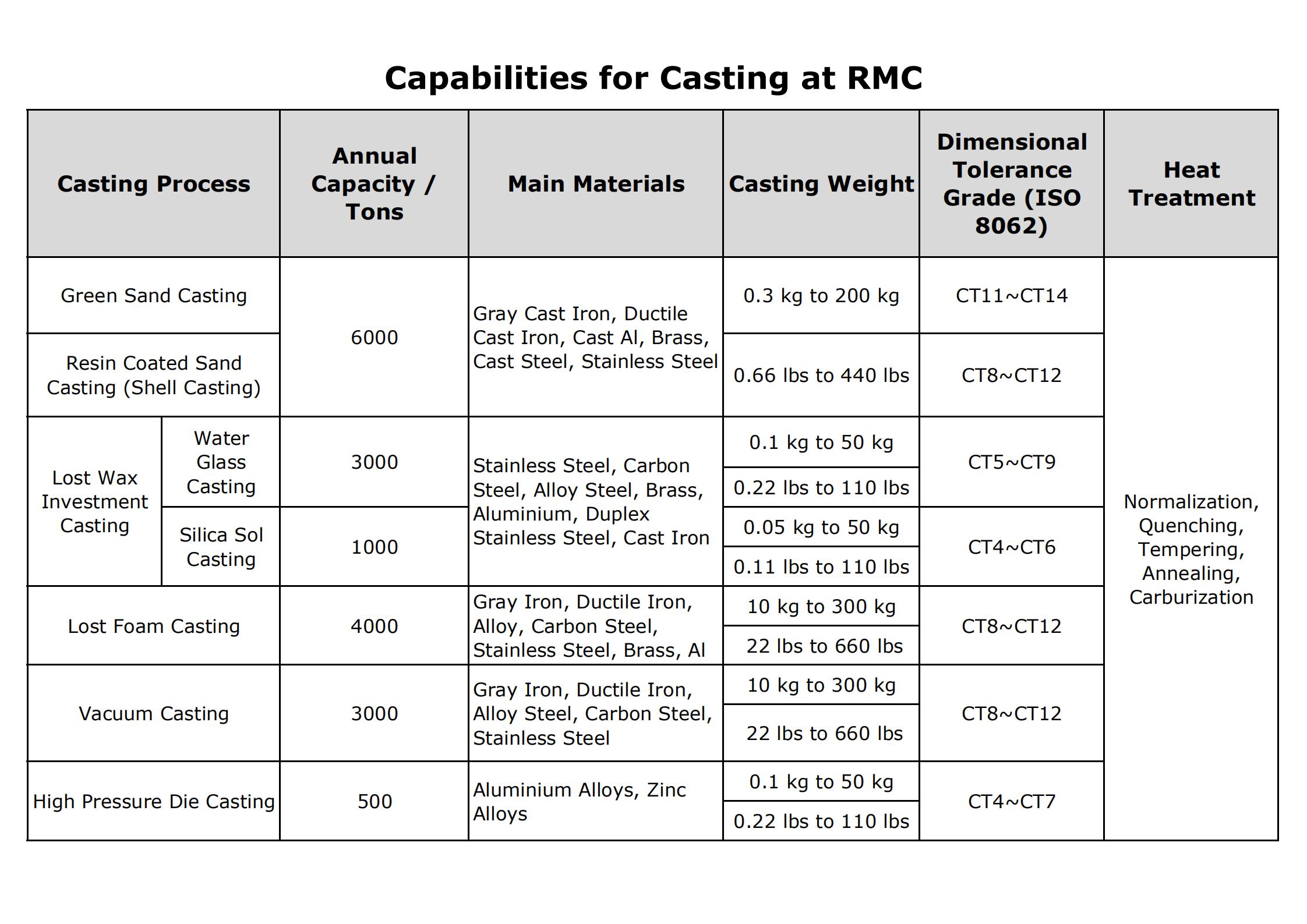

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

Product detail pictures:

Related Product Guide:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Best quality Steel Investment Casting Supplier - Stainless Steel Lost Wax Casting Product – RMC Foundry, The product will supply to all over the world, such as: Morocco , Leicester , Swaziland , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Cheap price Carbon Steel Investment Casting Fou...

-

Factory Cheap Hot Gray Iron Sand Casting Foundr...

-

PriceList for Carbon Steel Shell Casting - Duc...

-

Big discounting Alloy Steel Casting Supplier - ...

-

China Manufacturer for Cnc Machining Services -...

-

High Quality Vacuum Casting Parts - Alloy Stee...