8 Year Exporter Ductile Iron Foundry - Stainless Steel Investment Casting Pump Body – RMC Foundry Detail:

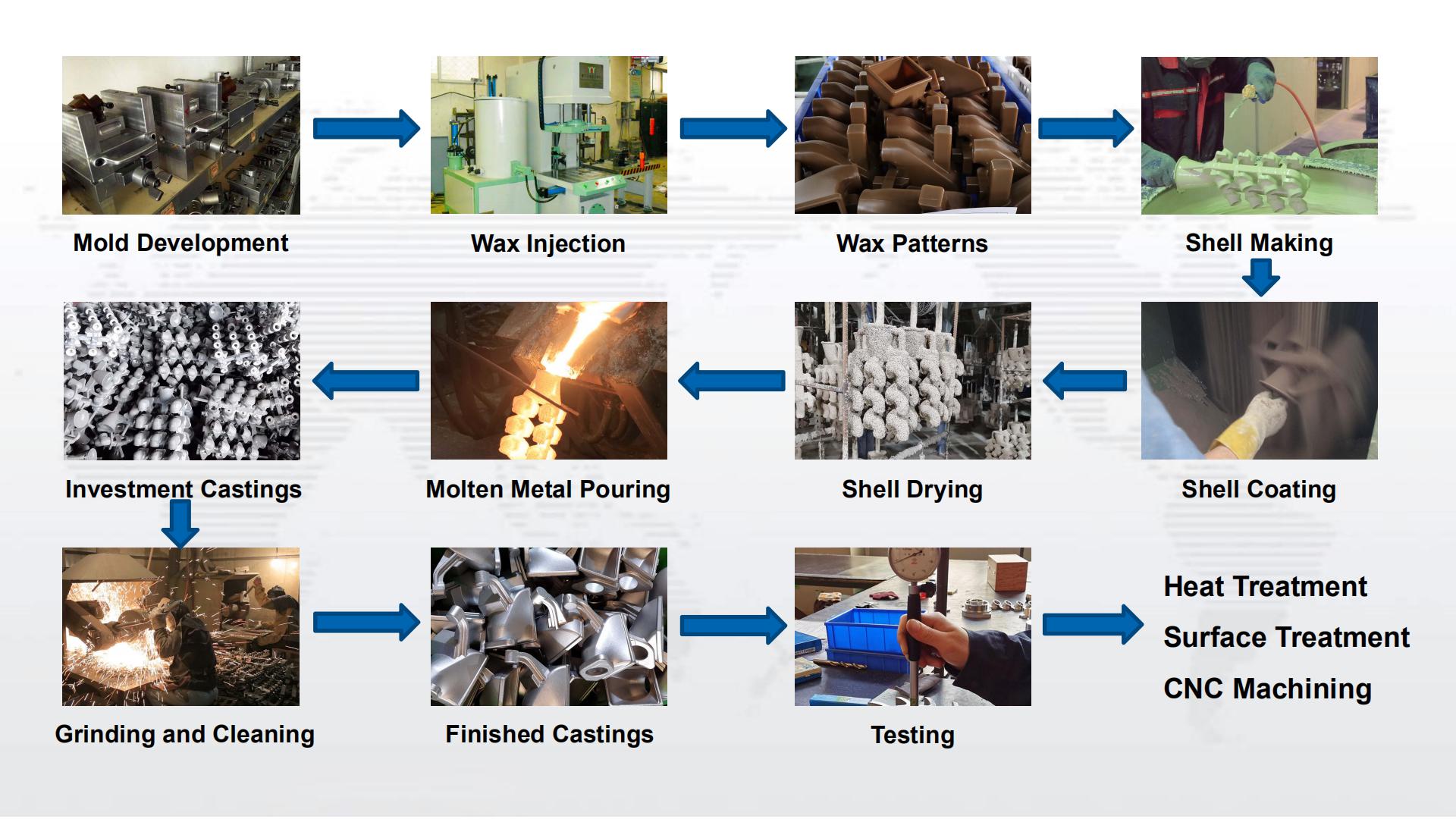

OEM custom stainless steel casting pump body with CNC machining services and heat treatment services from China casting foundry.

Stainless steel has a minimum Cr content of 11.5%, and other alloy elements such as Ni and Mo, making it more resistant to corrosive liquid environments and to oxidation. It has high corrosion resistant and wear resistant performances, provides excellent machinability, and is also well-known for its aesthetic appearance. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

Silica sol casting process is the main steel investment casting process of RMC investment casting foundry. We have been developing new technology of adhesive material to achieve much more economical and effective adhesive material to build the slurry shell. It is a overwhelming trend that Silica sol casting process replaces the rough inferior water glass process, especially for stainless steel casting and alloy steel casting. Besides the innovated molding material, the silica sol casting process has also being innovated to much steadier and less heat expanding.

| Materials for Investment Casting Process at RMC Foundry

|

|||

| Category | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless steel | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 |

302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 |

1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Steel | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo |

309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35-1, INCOLOY600, INCOLOY625 |

2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy |

ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 |

C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Product detail pictures:

Related Product Guide:

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for 8 Year Exporter Ductile Iron Foundry - Stainless Steel Investment Casting Pump Body – RMC Foundry, The product will supply to all over the world, such as: Ethiopia , Las Vegas , Pakistan , Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.