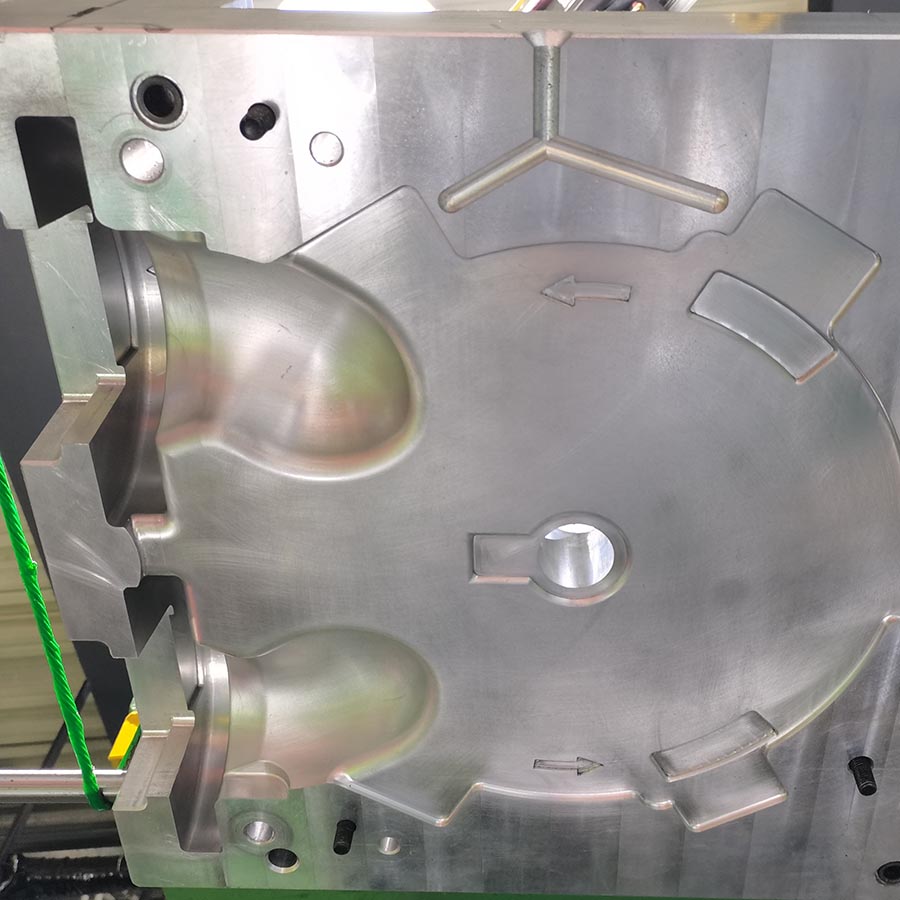

Rapid Prototype Carbon Steel Casting – Stainless Steel AISI 316 Investment Casting Pump Housing – RMC Foundry Detail:

OEM custom stainless steel castings produced by lost wax investment casting and CNC machining services. The AISI 316 / CF8M stainless steel are widely used to produce the stainless steel pump housing or end cover due to its good anti-rust performance.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. It is highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or “moly”). These three components will determine the casting’s grain structure and mechanical properties and will be instrumental in the casting’s ability to combat heat, wear, and corrosion.

Our foundry can manufacture custom stainless steel investment castings that match your exact design specifications. For parts ranging from tens of grams to tens of kilograms or more, we provide tight tolerances and consistent part to part repeatability.

Commonly, the stainless steel should be cast by the investment precision casting process with the silica sol as the bond. The stainless steel silica sol castings have a very high grade of precision surface and performance.

Due to its unique physical properties, stainless steel castings are popular in a wide range of applications, especially those in harsh environments. Common markets for stainless steel investment castings include oil and gas, fluid power, transportation, hydraulic systems, food industry, hardware and locks, agriculture…etc.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

▶ Main Process of Investment Casting

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ How We Inspect Lost Wax Castings

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

▶ Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Anodizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding.

▶ Advantages of Investment Casting Process:

• Excellent and smooth surface finish

• Tight dimensional tolerances.

• Complex and intricate shapes with design flexibility

• Capability to cast thin walls therefore a lighter casting component

• Wide selection of cast metals and alloys (ferrous and non-ferrous)

• Draft is not required in the molds design.

• Reduce the need for secondary machining.

• Low material waste.

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Rapid Prototype Carbon Steel Casting – Stainless Steel AISI 316 Investment Casting Pump Housing – RMC Foundry, The product will supply to all over the world, such as: Boston , Brisbane , Jamaica , With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,