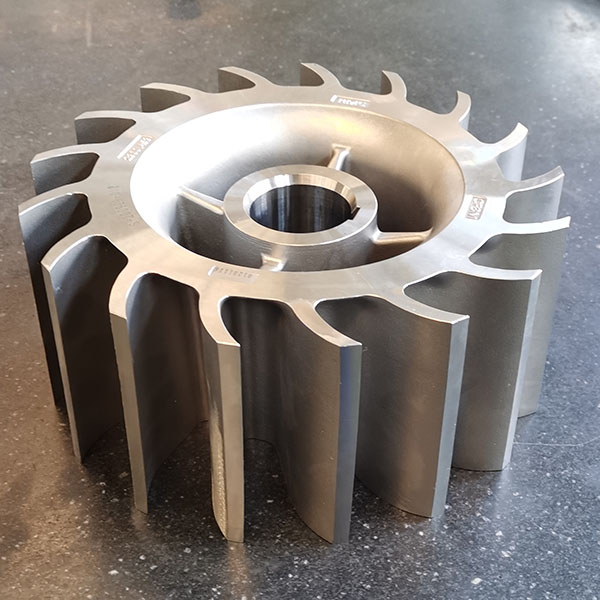

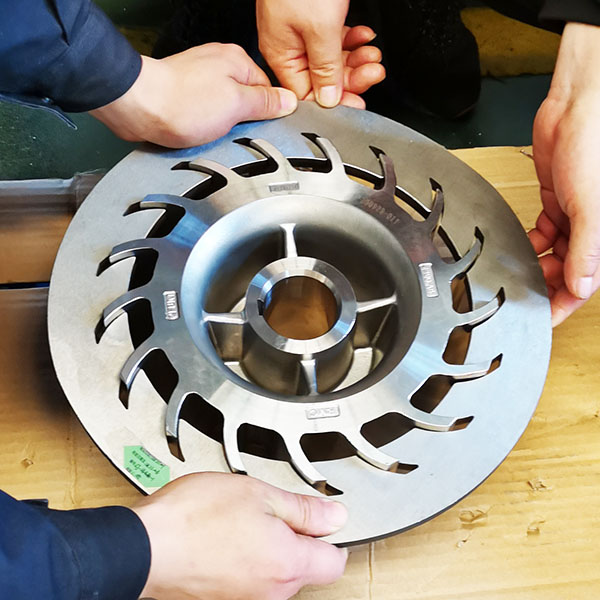

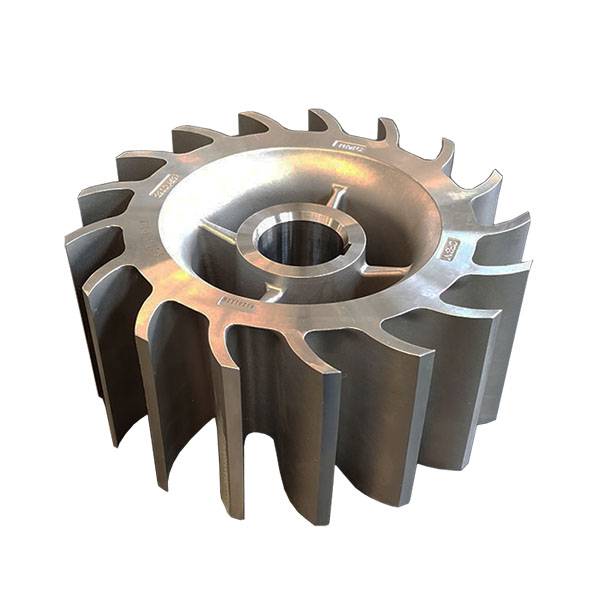

Wholesale Steel Lost Wax Casting Parts - CNC Machined Stainless Steel Cast Parts – RMC Foundry Detail:

Stainless steel cast and machined impellers by investment casting and CNC precision machining processes from China casting company.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | General Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

▶ Available Machining Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for CNC Machined Parts:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Alloy steel and stainless steel from standard grades to special grades on request.

▶ Available Non-Ferrous Metal Materials for CNC Machining:

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex

• Heat-resistant Steel, Corrosion-resistant Steel and other metal with special mechanical properties.

▶ Our In-house Machining Workshop Give Our Customers the Following Advantages:

• Short lead time for machined castings and forgings.

• Only one contact for castings, forgings and machining.

• Fast transmission between foundry and machining workshop.

• Well communication inside our systems and with our customers.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

Product detail pictures:

Related Product Guide:

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Wholesale Steel Lost Wax Casting Parts - CNC Machined Stainless Steel Cast Parts – RMC Foundry, The product will supply to all over the world, such as: Germany , Adelaide , Hanover , As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

Wholesale Bronze Vacuum Casting - Steel Vacuum...

-

Hot New Products Ductile Iron Sand Casting Prod...

-

Factory Cheap Hot Alloy Steel Lost Foam Casting...

-

Factory wholesale Gray Iron Investment Casting ...

-

Renewable Design for Aluminium Alloy Gravity Ca...

-

Wholesale Iron Sand Casting Factory - Sand Mol...