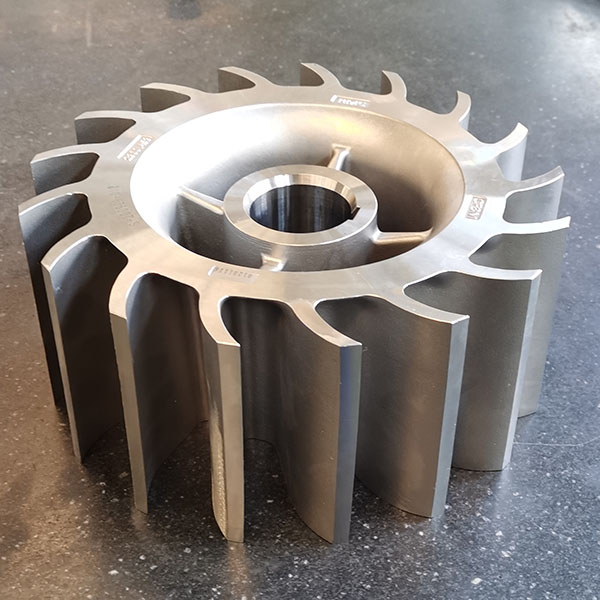

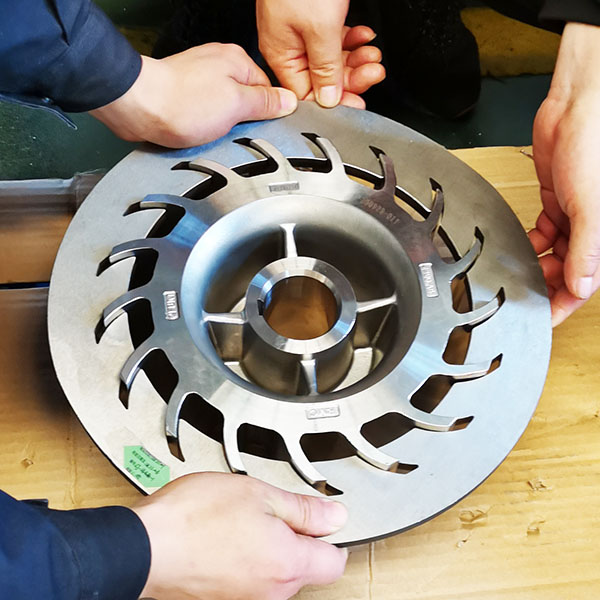

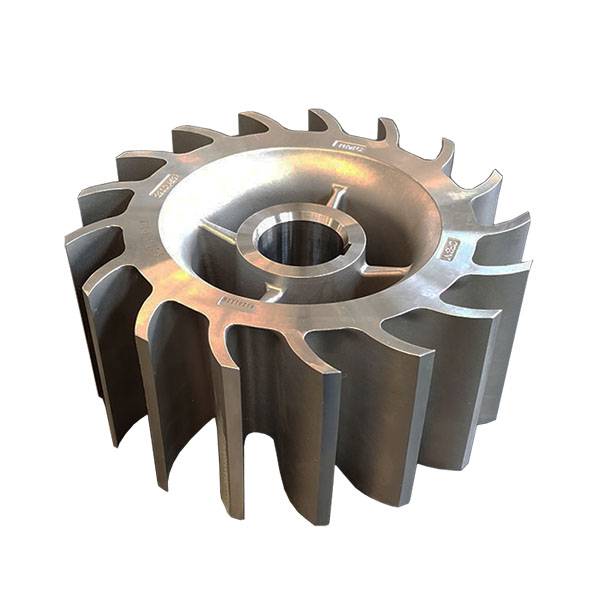

Quality Inspection for Copper Casting Foundry - CNC Machined Stainless Steel Parts – RMC Foundry Detail:

Stainless steel cast and machined impellers by investment casting and CNC precision machining processes from China casting company.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | General Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

▶ Available Machining Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for CNC Machined Parts:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Alloy steel and stainless steel from standard grades to special grades on request.

▶ Available Non-Ferrous Metal Materials for CNC Machining:

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex

• Heat-resistant Steel, Corrosion-resistant Steel and other metal with special mechanical properties.

▶ Our In-house Machining Workshop Give Our Customers the Following Advantages:

• Short lead time for machined castings and forgings.

• Only one contact for castings, forgings and machining.

• Fast transmission between foundry and machining workshop.

• Well communication inside our systems and with our customers.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Quality Inspection for Copper Casting Foundry - CNC Machined Stainless Steel Parts – RMC Foundry, The product will supply to all over the world, such as: Mali , Lithuania , Seattle , With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

Special Price for Stainless Steel Lost Wax Cast...

-

Factory Supply Gray Iron Shell Casting - Gray ...

-

Factory Outlets Stainless Steel Casting Foundry...

-

Factory wholesale Carbon Steel Casting Company ...

-

OEM/ODM China Malleable Iron Sand Casting Found...

-

Special Design for Stainless Steel Casting Comp...