Massive Selection for Brass Casting Foundry - Precipitation Hardening Stainless Steel Casting – RMC Foundry Detail:

OEM custom investment casting products made of precipitation hardening stainless steel from China foundry.

Precipitation hardening stainless steel refers to the kind of stainless steel which adds different types and quantities of strengthening elements, and different types and quantities of carbides, nitrides, carbonitrides and intermetallic compounds are precipitated through the precipitation hardening process. Precipitation hardening stainless steel not only has high strength, but also has good toughness and corrosion resistance. For precipitation hardening steel castings containing copper, the hardness of the steel castings is increased due to the precipitation of hard copper-rich phases in the as-cast state during the cooling process. In order to soften the structure and improve the processing performance, such steel castings require solution heat treatment. The solid solution temperature of precipitation hardening steel castings containing copper is generally 900 ℃ ~ 950 ℃. After cooling, a supersaturated single-phase structure with a copper mass fraction of 1.0% ~ 1.5% can be obtained.

Precipitation hardening stainless steel is widely used in advanced industries. For example, the typical precipitation hardening stainless steel 17-4PH can be used to make structures below 370°C that require corrosion resistance, wear resistance, and high strength.

RMC Foundry Cast the Following Typical Grades of Precipitation Hardening Stainless Steel

1- Chinese standards: 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb

2- British Standard: ANC20, ANC21, ANC22

3- American standards: 630, 634, 17-4PH, 15-5PH, CB7Cu-1

4- Japanese standards: SCS24, SCS32

5- German Standard: 1.4542

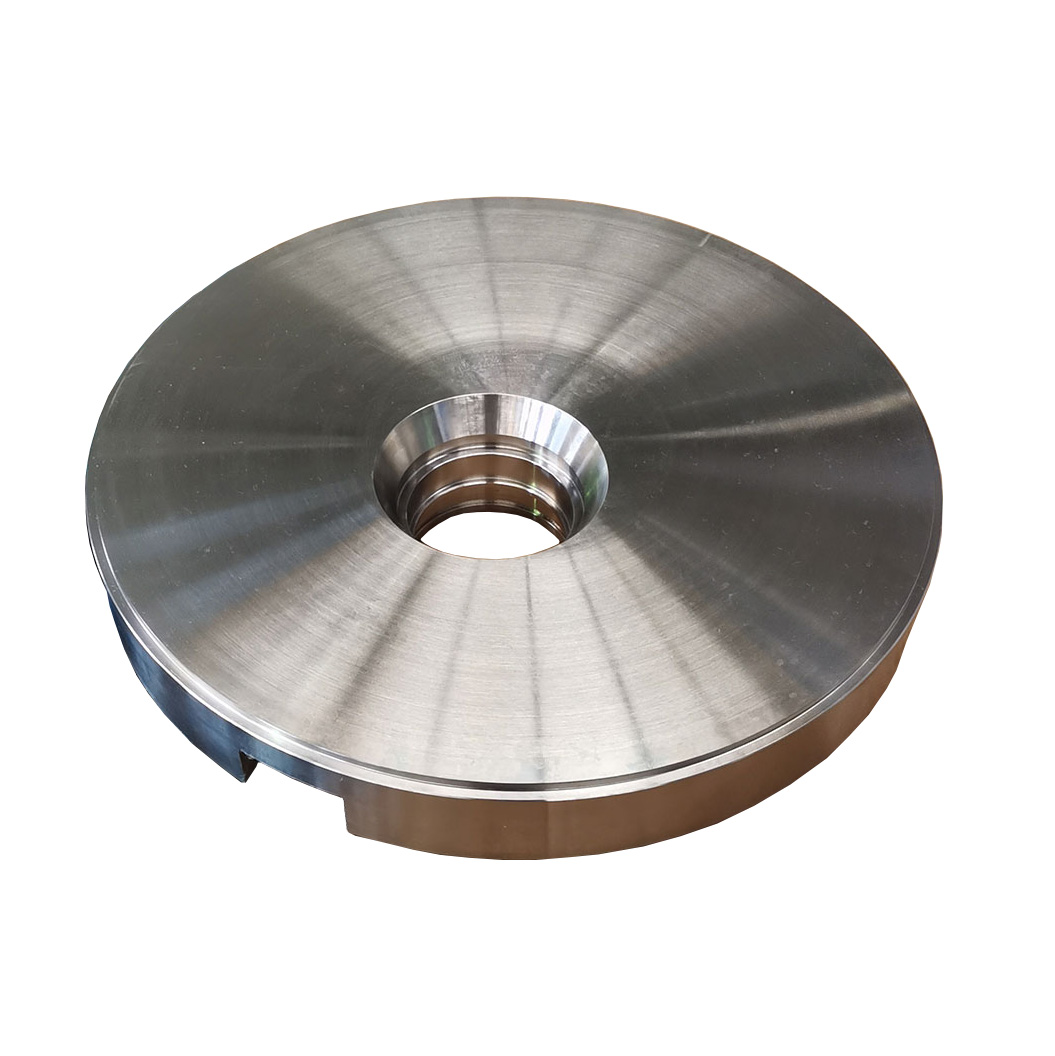

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Massive Selection for Brass Casting Foundry - Precipitation Hardening Stainless Steel Casting – RMC Foundry, The product will supply to all over the world, such as: Austria , Provence , Myanmar , Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

-

Wholesale Price China China Machining Factory -...

-

Cheap price Malleable Iron Sand Casting Supplie...

-

Wholesale Price Carbon Steel Vacuum Casting - ...

-

Discount Price Gray Iron Casting Supplier - CF...

-

100% Original Steel Lost Wax Casting Products -...

-

2020 High quality Shell Mold Casting Products -...