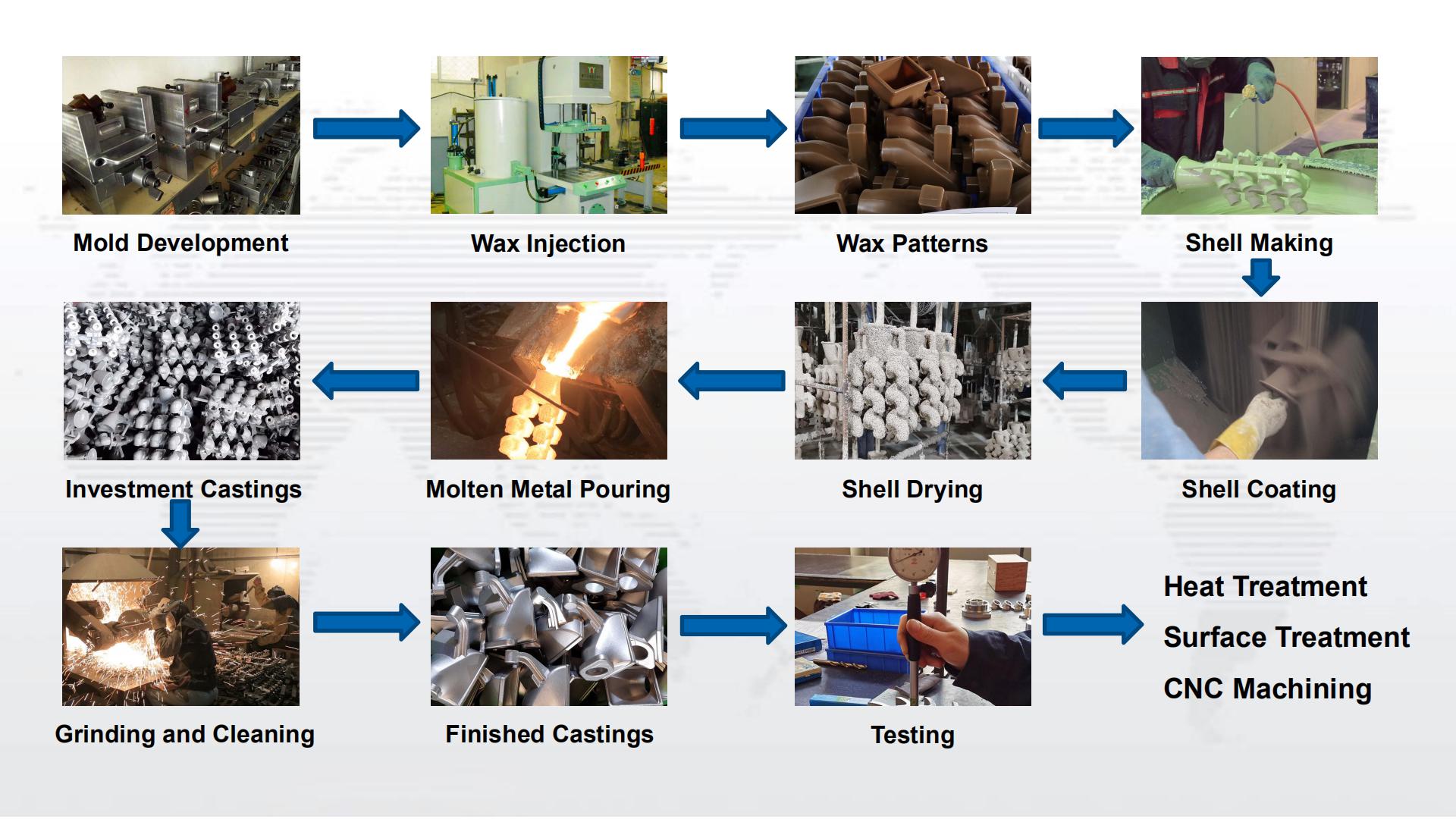

Factory Price Alloy Steel Casting Foundry - Duplex Stainless Steel Lost Wax Casting – RMC Foundry Detail:

OEM custom duplex stainless steel lost wax casting with heat treatment, surface treatment, CNC machining and testing services from one single supplier in China

RMC Foundry is capable of meeting material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST and GB standards. We have more than 100 different ferrous and non-ferrous alloys with which we cast parts using complex design criteria. Our dimensionally and geometrically complex investment castings are produced to net shape, minimizing the need for secondary machining.

Duplex Stainless Steel (DSS) refers to stainless steel with ferrite and austenite each accounting for about 50%. Generally, the content of less phases needs to be at least 30%. In the case of low C content, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some duplex stainless steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

The DSS has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and ductility, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining brittleness, high thermal conductivity, and superplasticity as ferrite stainless steel.

Compared with austenitic stainless steel, DSS has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

Our top-of-the-line equipment and automation process controls allow for consistent and repeatable tolerances as close as ± 0.1 mm. Our castings can also be produced in a wide size range—they may be as small as 10 mm long x 10 mm wide x 10 mm high and weigh as little as 0.01 kg, or as much as 1000 mm in length and weigh as much as 100 kg.

At RMC Foundry, we pride ourselves in offering our customers the highest-quality service from start to finish. Our services include:

- - In-house tooling design and manufacturing capabilities.

- - Prototype development.

- - Process research and development.

- - Manufacturing flexibility.

- - Qualification and testing.

- - Heat Treatment

- - Surface Treatment

- - Outsourcing Manufacturing Capabilities

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for Factory Price Alloy Steel Casting Foundry - Duplex Stainless Steel Lost Wax Casting – RMC Foundry, The product will supply to all over the world, such as: Florence , America , Istanbul , As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

-

Hot sale Factory Alloy Steel Casting Manufactur...

-

Professional Design Steel Casting Company - No...

-

Factory Price For Bronze Gravity Casting - Ste...

-

China wholesale Ductile Iron Shell Mold Casting...

-

2020 Good Quality Shell Mold Casting Company - ...

-

Special Price for Stainless Steel Lost Wax Cast...