Big Discount Steel Casting Supplier - CNC Precision Machining Components – RMC Foundry Detail:

The CNC precision machining workshop at RMC takes care probably the most important step in the supply chain after casting. State-of-the-art vertical and horizontal CNC machining centers and other CNC machines could make sure the accuracy of the castings and guarantee the machined castings are finished on time. All machines are well-organized and taken into production at high production effeciency and good cost-effective mothods. If needed, all the machined dimensions could be measured by the CMM and the related reports could be issued as per customer’s requirements.

▶ Equipment for CNC Machining Components:

• Convertional Machining Machines: 20 sets.

• CNC Machines: 60 sets.

• 3-Axis Machining Center: 10 sets.

• 4-Axis Machining Center: 5 sets.

• 5-Axis Machining Center: 2 sets

▶ CNC Precision Machining Capabilities

• Max Size: 1,500 mm × 800 mm × 500 mm

• Weight Range: 0.1 kg – 500 kg

• Annual Capacity: 10,000 tons

• Accuracy: As per standards: …. or on request. Minimum ±0.003 mm

• Holes to ±0.002 mm dia.

• Flatness, Roundness and Straightness: As per standards or on request.

▶ Available Process

• Turning

• Milling

• Lathing

• Drilling

• Honing, Grinding.

• Washing

▶ Available Ferrous Metal Materials for Precision Machining Components:

• Cast Iron including gray iron and ductile iron

• Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

• Steel Alloys from standard grades to special grades on request.

• Aluminum and their alloys

• Brass and Copper

• Zinc and their alloys

• Stainless Steel, Duplex, Corrosion-resistant Steel, High-temperature Steel.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

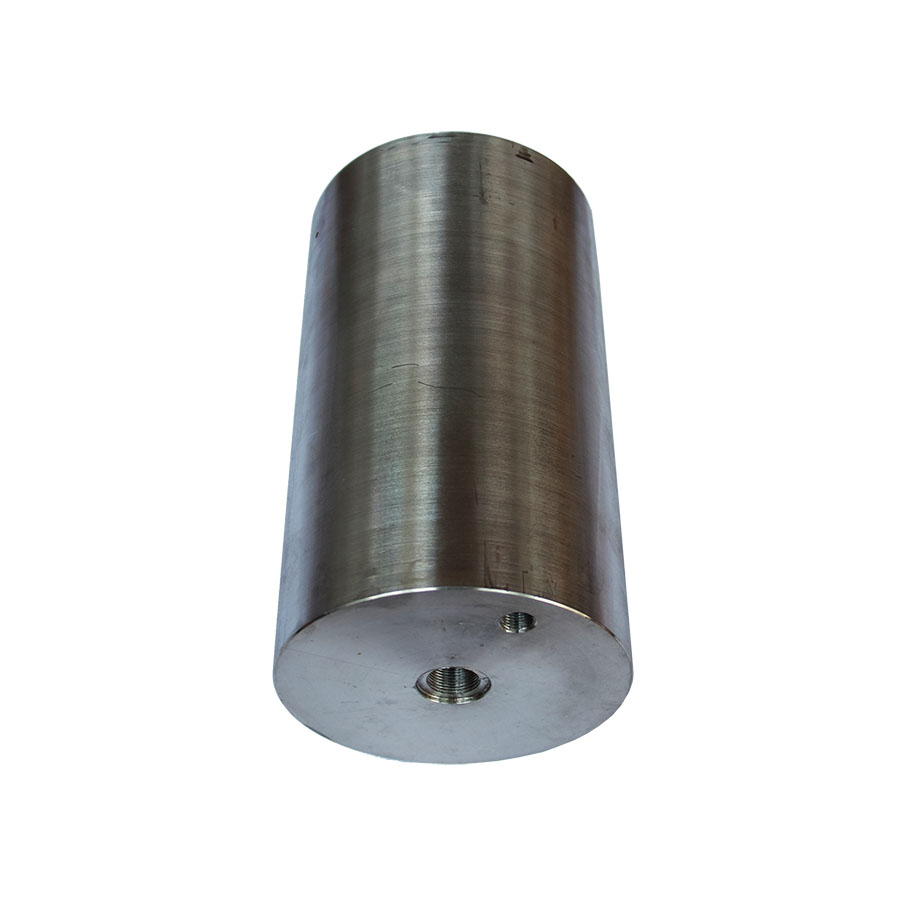

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients for Big Discount Steel Casting Supplier - CNC Precision Machining Components – RMC Foundry, The product will supply to all over the world, such as: Doha , South Korea , Lebanon , Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

Ordinary Discount Metal Casting Foundry - Lost...

-

Good User Reputation for Machining Services - ...

-

Chinese Professional Stainless Steel Vacuum Cas...

-

Factory directly Steel Precision Casting Suppli...

-

Ordinary Discount Metal Casting Foundry - CNC ...

-

Factory wholesale Stainless Steel Casting Produ...