Both the gray iron and ductile iron could be cast by sand casting process, shell molding casting process (resin coated sand), lost foam casting, vacuum casting and investment casting. Sand casting is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost. Not only does this method allow manufacturers to create products at a low cost, but there are other benefits to sand casting, such as very small-size operations. Sand casting also allows most metals to be cast, depending on the type of sand used for the molds. Shell molding casting process is also called pre-coated resin sand casting process, hot shell molding castings or core casting process. The main molding material is the pre-coated phenolic resin sand, which is more expensive than green sand and furan resin sand. Moreover, this sand can not be recycle used. The shell molding iron casting parts have higher costs than sand casting. However, the shell molding casting parts have many advantages such as tighter dimensional tolerance, good surface quality and less casting defects.

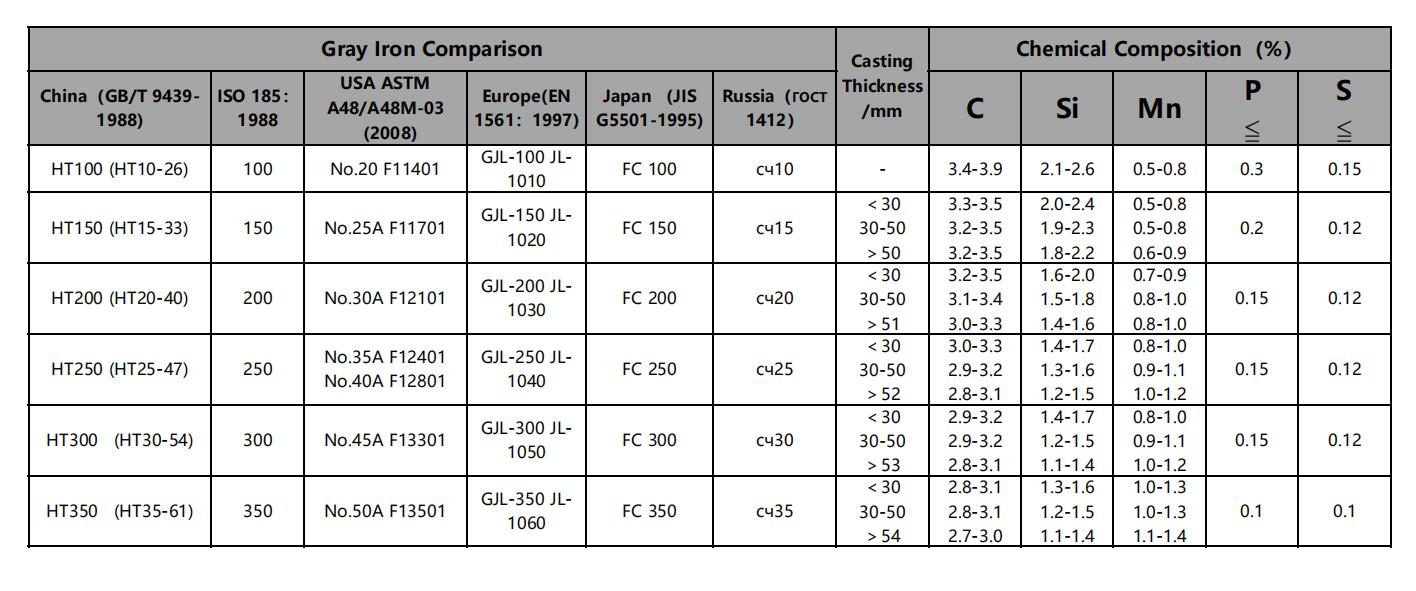

However, there are still some differences between the gray iron casting parts and ductile iron casting parts. Gray Iron Sand Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other metal-forming processes. Thanks to its ease of machining, high compressive strength, better thermal conductivity and excellent vibration absorption, the gray cast iron is one of the most widely used casting metal for a very long time, even in current industry production. Carbon content is by far the most important element for gray iron (usually 2% to 4%) to create tensile strength and machinability. When molten cast iron solidifies some of the carbon precipitates as graphite, forming tiny, irregular flakes within the crystal structure of the metal which enhances the desirable properties of cast iron, the flakes disrupt the crystal structure leading to cast iron's characteristic brittleness.

The development of gray cast iron is mainly driven by high strength. In the past, the main way to improve the performance of gray cast iron was inoculation. In recent years, the main approach now is to focus on alloying, and in order to improve casting performance, many gray iron foundries use cast iron with a higher carbon equivalent. This is particularly important for low alloy cast iron. Therefore, the gray cast iron is suitable material to produce iron casting parts of engine block, machinery housing, machine base, counter weights, stove parts, boiler parts, pump shells and so on.

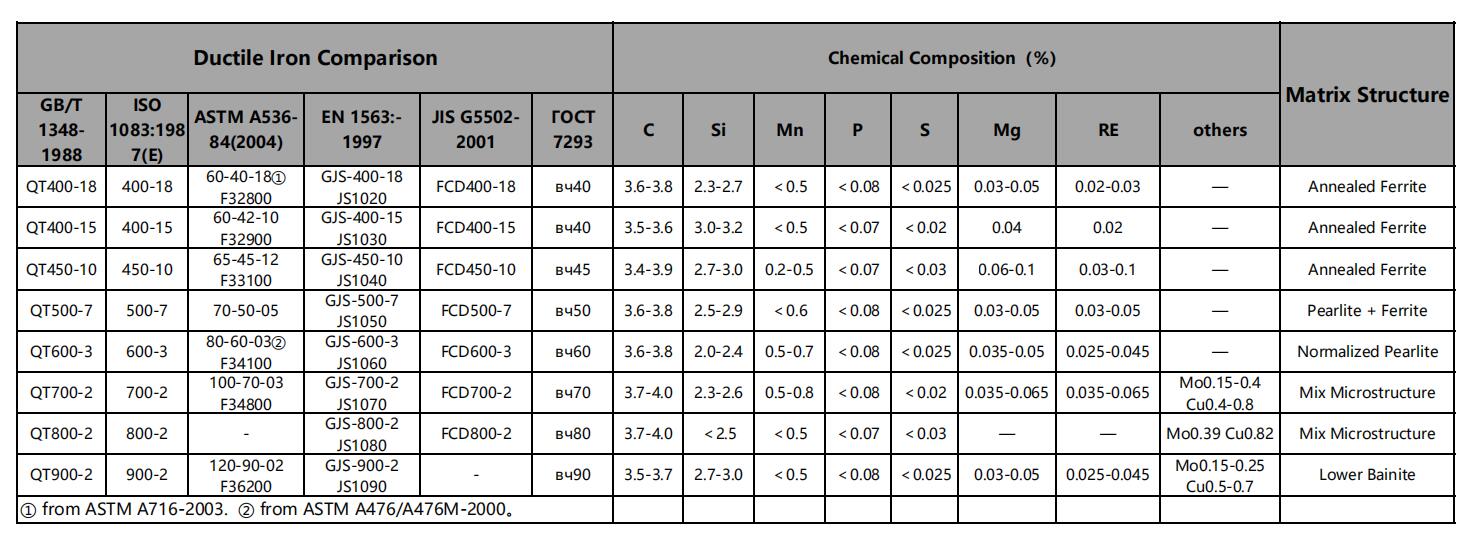

Ductile iron offers design flexibility and reduced manufacturing costs versus welded fabrications and forgings. In the microstructure of ductile iron, the graphite forms into spherical nodules instead of flakes, thus inhibiting the creation of cracks and providing the enhanced ductility that gives the alloy its name. Ductile iron has higher tensile strength and toughness similar to steel. Ductile iron castings have many characteristics, however, are not always the most cost-effective alternative to other ferrous alloys. Additionally, ductile irons are widely used in numerous manufacturing industries, including agriculture, automotive, hydraulics, rail trains, commercial trucks and aerospace industries.

Post time: Jan-27-2021