Machines operating under different conditions require gray cast iron components to have service properties that cannot simply be characterized by conventional mechanical properties. Designers and manufacturers must give this due attention.

Wear Resistance

Gray cast iron parts that require wear resistance mostly operate under sliding conditions. Brake shoes, brake disc, clutch plates, cylinder liners, piston rings, machine tool guideways, bearings, hydraulic valve bodies, etc. are typical examples. Depending on the working conditions, they can be divided into dry friction and lubricated friction types. According to their failure modes, they can also be divided into abrasive wear, adhesive wear, contact fatigue wear, and corrosive wear. In practice, several types of wear often occur simultaneously, but one or two types usually predominate. Parts working under different conditions and failing due to different wear mechanisms will require different material properties.

When the cleanliness of the air or the lubricating medium is good, components under sliding friction often fail due to adhesive wear or seizure. For these parts, good thermal conductivity on the friction surface, good friction properties, sufficient strength to eliminate volume changes caused by phase transformation, low elastic modulus, and the ability to reduce thermal stresses are essential.

Vibration Damping

The flake graphite in gray cast iron promotes microscopic plastic deformation and dislocations under cyclic stress, causing vibrational energy to dissipate irreversibly. This accelerates vibration attenuation. Hence, gray cast iron exhibits excellent damping capacity, making it an important reason for its widespread use in the manufacture of internal combustion engines and machine tool components.

Relative Vibration Damping Properties of Different Materials

|

Material Name |

Relative Vibration Damping |

|

Coarse Flake Graphite Gray Cast Iron |

100 ~ 500 |

|

Fine Flake Graphite Gray Cast Iron |

20 ~ 100 |

|

8 ~ 15 |

|

|

Ductile Cast Iron |

5 ~ 20 |

|

Pure Iron |

5 |

|

Eutectoid Steel |

4 |

|

White Cast Iron |

2 ~ 4 |

|

Aluminum |

0.4 |

1.jpg)

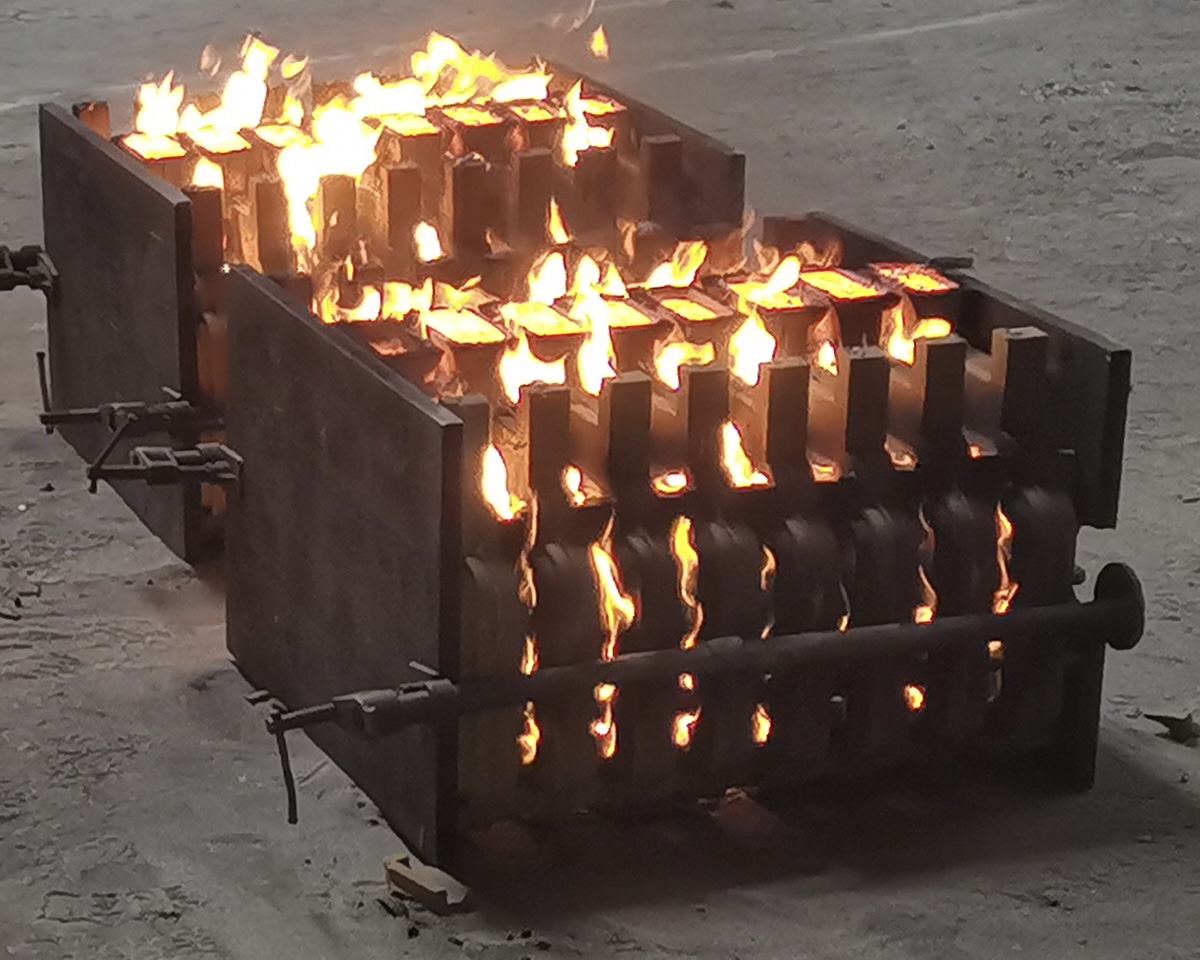

Thermal Fatigue Resistance

When cast iron is repeatedly heated and cooled, different thermal expansions and strains occur in different areas due to temperature gradients, generating thermal stresses. Repeated heating may also cause pearlite decomposition, resulting in volume changes and localized oxidation. These factors, together with the component' s original load, can produce total stresses exceeding the material' s strength and eventually cause cracking. This is a complex process that cannot be represented by any single property of the material; rather, it is related to strength, thermal conductivity, coefficient of thermal expansion, elastic modulus, and so on.

Oxidation and Growth Resistance

When cast iron is exposed to high temperatures or repeatedly heated and cooled, it can experience irreversible expansion, known as "growth". This depends on the decomposition of carbides and pearlite in the matrix, as well as inward-progressing surface oxidation. Both phenomena affect the dimensional stability of the iron in service. Excessive deformation can lead to component failure.

Six years of testing have shown that ordinary gray cast iron hardly oxidizes or grows at temperatures below 350°C in air. Under 700°C, its oxidation is slight but some growth occurs, resulting in dimensional changes. Above 700°C, both oxidation and growth increase dramatically.

Post time: Jun-26-2025