The heat treatment of steel castings is based on the Fe-Fe3C phase diagram to control the microstructure of the steel castings to achieve the required performance. Heat treatment is one of the important processes in the production of steel castings. The quality and effect of heat treatment are directly related to the final performance of steel castings.

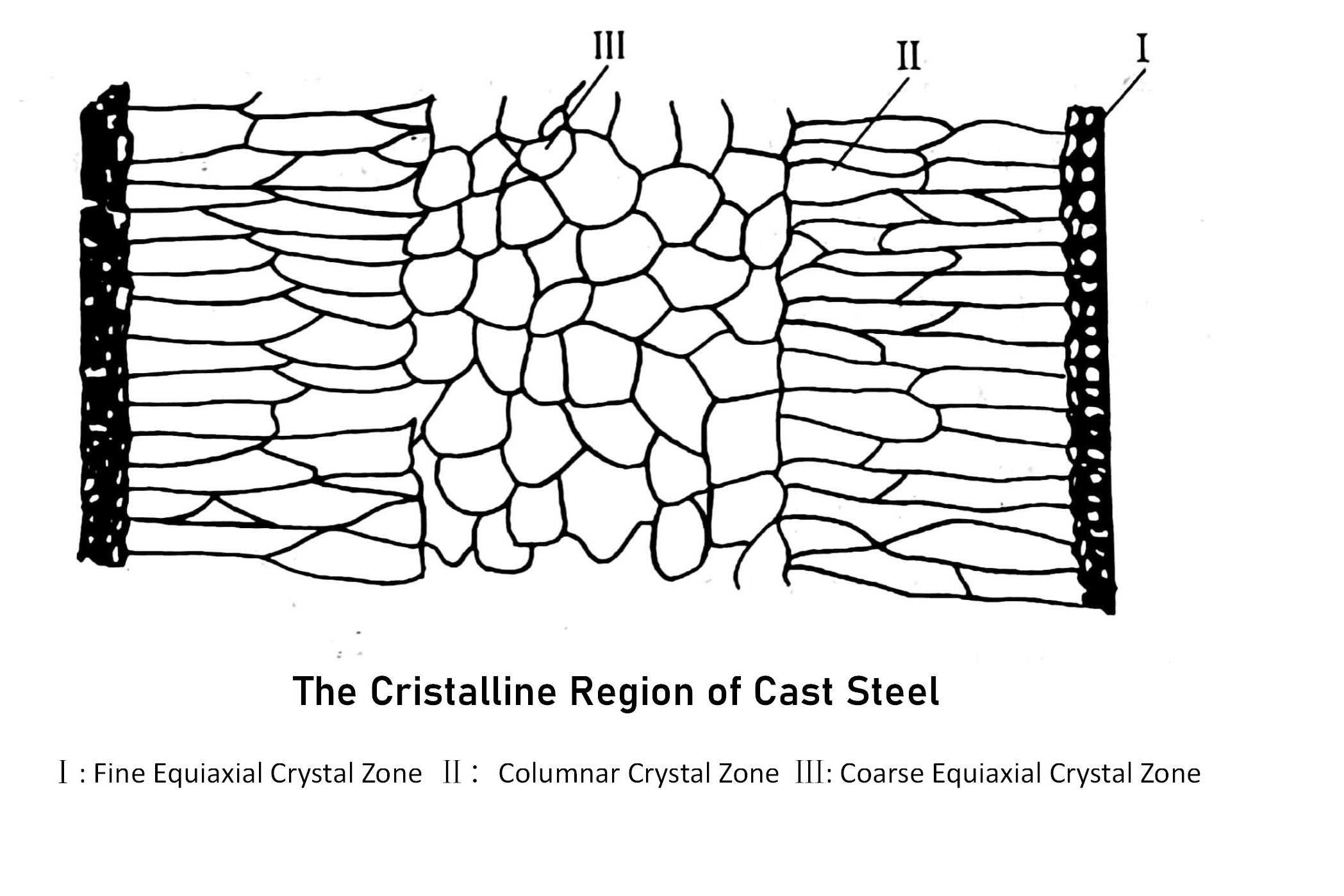

The as-cast structure of steel castings depends on the chemical composition and solidification process. Generally, there are relatively serious dendrite segregation, very uneven structure and coarse grains. Therefore, steel castings generally need to be heat treated to eliminate or reduce the impact of the above problems, so as to improve the mechanical properties of steel castings. In addition, due to the difference in the structure and wall thickness of the steel castings, various parts of the same casting have different organizational forms and generate considerable residual internal stress. Therefore, steel castings (especially alloy steel castings) should generally be delivered in a heat-treated state.

1. The Characteristics of The Heat Treatment of Steel Castings

1) In the as-cast structure of steel castings, there are often coarse dendrites and segregation. During the heat treatment, the heating time should be slightly higher than that of the forging steel parts of the same composition. At the same time, the holding time of austenitization needs to be appropriately extended.

2) Due to the serious segregation of the as-cast structure of some alloy steel castings, in order to eliminate its influence on the final properties of the castings, measures should be taken to homogenize during heat treatment.

3) For steel castings with complex shapes and large wall thickness differences, cross-sectional effects and casting stress factors must be considered during heat treatment.

4) When heat treatment is performed on steel castings, it must be reasonable based on its structural characteristics and try to avoid deformation of the castings.

2. The Main Process Factors of the Heat Treatment of Steel Castings

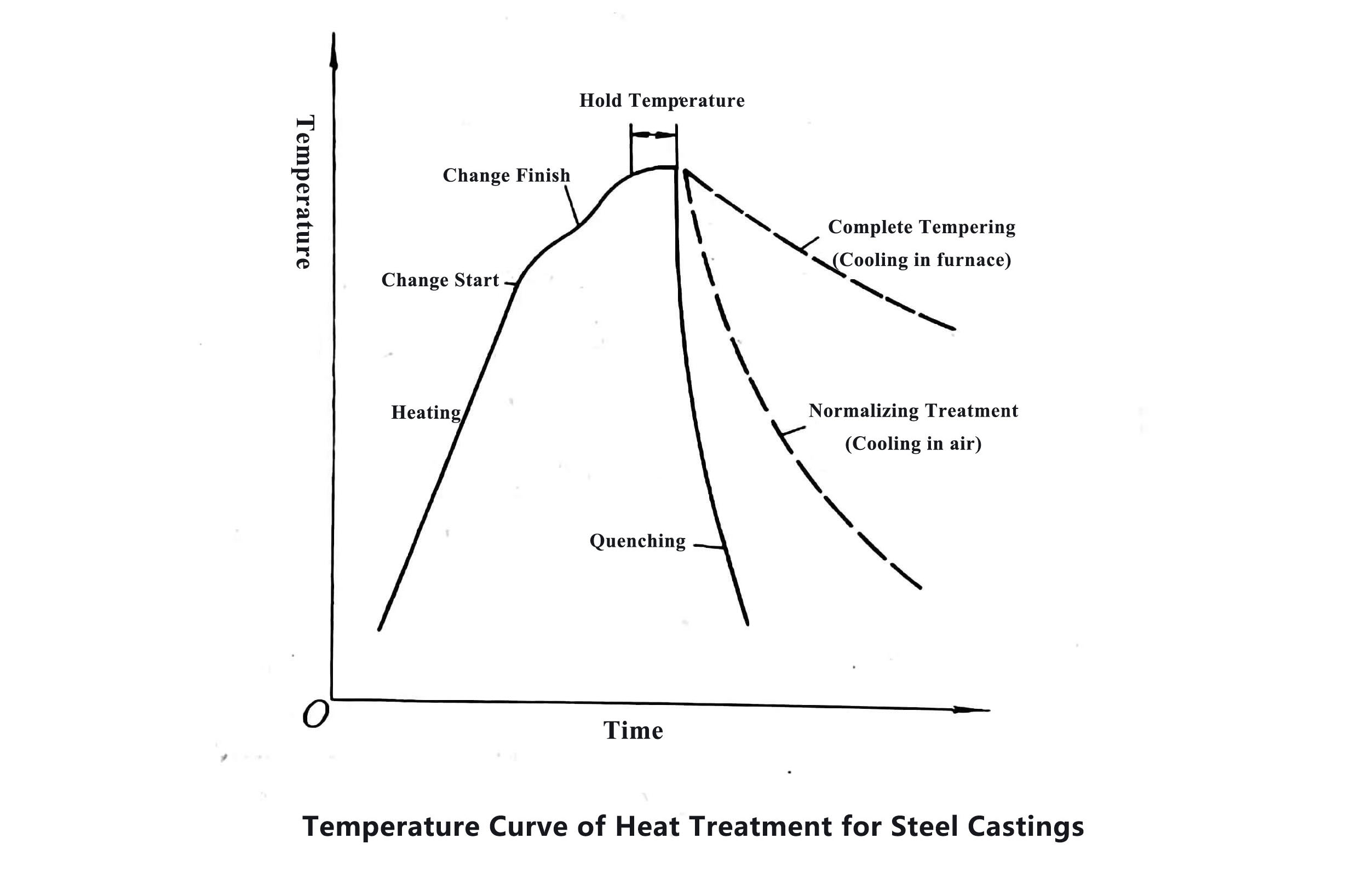

The heat treatment of steel castings consists of three stages: heating, heat preservation, and cooling. The determination of process parameters should be based on the purpose of ensuring product quality and saving costs.

1) Heating

Heating is the most energy-consuming process in the heat treatment process. The main technical parameters of the heating process are to select an appropriate heating method, heating speed and charging method.

(1) Heating method. The heating methods of steel castings mainly include radiant heating, salt bath heating and induction heating. The selection principle of heating method is fast and uniform, easy to control, high efficiency and low cost. When heating, the foundry generally considers the structural size, chemical composition, heat treatment process and quality requirements of the casting.

(2) Heating speed. For general steel castings, the heating speed may not be limited, and the maximum power of the furnace is used for heating. The use of hot furnace charging can greatly shorten the heating time and production cycle. In fact, under the condition of rapid heating, there is no obvious temperature hysteresis between the surface of the casting and the core. Slow heating will result in reduced production efficiency, increased energy consumption, and serious oxidation and decarburization on the surface of the casting. However, for some castings with complex shapes and structures, large wall thicknesses, and large thermal stresses during the heating process, the heating speed should be controlled. Generally, low temperature and slow heating (below 600 °C) or staying at low or medium temperature can be used, and then rapid heating can be used in high temperature areas.

(3) Loading method. The principle that steel castings should be placed in the furnace is to make full use of the effective space, ensure uniform heating and place the castings to deform.

2) Insulation

The holding temperature for austenitization of steel castings should be selected according to the chemical composition of the cast steel and the required properties. The holding temperature is generally slightly higher (about 20 °C) than forging steel parts of the same composition. For eutectoid steel castings, it should be ensured that carbides can be quickly incorporated into austenite, and that the austenite can maintain fine grains.

Two factors should be considered for the heat preservation time of steel castings: the first factor is to make the temperature of the casting surface and the core uniform, and the second factor is to ensure the uniformity of the structure. Therefore, the holding time mainly depends on the thermal conductivity of the casting, the wall thickness of the section and the alloy elements. Generally speaking, alloy steel castings require longer holding time than carbon steel castings. The wall thickness of the casting is usually the main basis for calculating the holding time. For the holding time of tempering treatment and aging treatment, factors such as the purpose of heat treatment, holding temperature and element diffusion rate should be considered.

3) Cooling

The steel castings can be cooled at different speeds after heat preservation, in order to complete the metallographic transformation, obtain the required metallographic structure and achieve the specified performance indicators. Generally speaking, increasing the cooling rate can help to obtain a good structure and refine the grains, thereby improving the mechanical properties of the casting. However, if the cooling rate is too fast, it is easy to cause greater stress in the casting. This may cause deformation or cracking of castings with complex structures.

The cooling medium for the heat treatment of steel castings generally includes air, oil, water, salt water and molten salt.

3. Heat Treatment Method of Steel Castings

According to different heating methods, holding time and cooling conditions, the heat treatment methods of steel castings mainly include annealing, normalizing, quenching, tempering, solution treatment, precipitation hardening, stress relief treatment and hydrogen removal treatment.

1) Annealing.

Annealing is to heat the steel whose structure deviates from the equilibrium state to a certain temperature predetermined by the process, and then slowly cool it after heat preservation (usually cooling with the furnace or burying in lime) to obtain a heat treatment process close to the equilibrium state of the structure. According to the composition of the steel and the purpose and requirements of annealing, annealing can be divided into complete annealing, isothermal annealing, spheroidizing annealing, recrystallization annealing, stress relief annealing and so on.

(1) Complete Annealing. The general process of complete annealing is: heating the steel casting to 20 °C-30 °C above Ac3, holding it for a period of time, so that the structure in the steel is completely transformed into austenite, and then slowly cooling (usually cooling with the furnace) at 500 ℃- 600 ℃, and finally cooled down in the air. The so-called complete means that a complete austenite structure is obtained when heated.

The purpose of complete annealing mainly includes: the first is to improve the coarse and uneven structure caused by hot working; the second is to reduce the hardness of carbon steel and alloy steel castings above medium carbon, thereby improving their cutting performance (in general, When the hardness of the workpiece is between 170 HBW-230 HBW, it is easy to cut. When the hardness is higher or lower than this range, it will make cutting difficult); the third is to eliminate the internal stress of the steel casting.

The use range of complete annealing. Full annealing is mainly suitable for carbon steel and alloy steel castings with hypoeutectoid composition with carbon content ranging from 0.25% to 0.77%. Hypereutectoid steel should not be fully annealed, because when the hypereutectoid steel is heated to above Accm and slowly cooled, the secondary cementite will precipitate along the austenite grain boundary in a network shape, which makes the strength, plasticity and impact toughness of the steel significant decline.

(2) Isothermal Annealing. Isothermal annealing refers to heating steel castings to 20 °C - 30 °C above Ac3 (or Ac1), after holding for a period of time, quickly cooling to the peak temperature of the subcooled austenite isothermal transformation curve, and then holding for a period of time ( Pearlite transformation zone). After the austenite is transformed into pearlite, it cools down slowly.

(3) Spheroidizing Annealing. Spheroidizing annealing is to heat the steel castings to a temperature slightly higher than Ac1, and then after a long time of heat preservation, the secondary cementite in the steel spontaneously transforms into granular (or spherical) cementite, and then at a slow speed Heat treatment process to cool to room temperature.

The purpose of spheroidizing annealing includes: reducing the hardness; making the metallographic structure uniform; improving the cutting performance and preparing for quenching.

Spheroidizing annealing is mainly applicable to eutectoid steels and hypereutectoid steels (carbon content greater than 0.77%) such as carbon tool steel, alloy spring steel, rolling bearing steel and alloy tool steel.

(4) Stress relief annealing and recrystallization annealing. Stress relief annealing is also called low temperature annealing. It is a process in which steel castings are heated to below Ac1 temperature (400 °C - 500 °C), then kept for a period of time, and then slowly cooled to room temperature. The purpose of stress relief annealing is to eliminate the internal stress of the casting. The metallographic structure of the steel will not change during the stress relief annealing process. Recrystallization annealing is mainly used to eliminate the distorted structure caused by cold deformation processing and eliminate work hardening. The heating temperature for recrystallization annealing is 150 °C - 250 °C above the recrystallization temperature. Recrystallization annealing can re-form the elongated crystal grains into uniform equiaxed crystals after cold deformation, thereby eliminating the effect of work hardening.

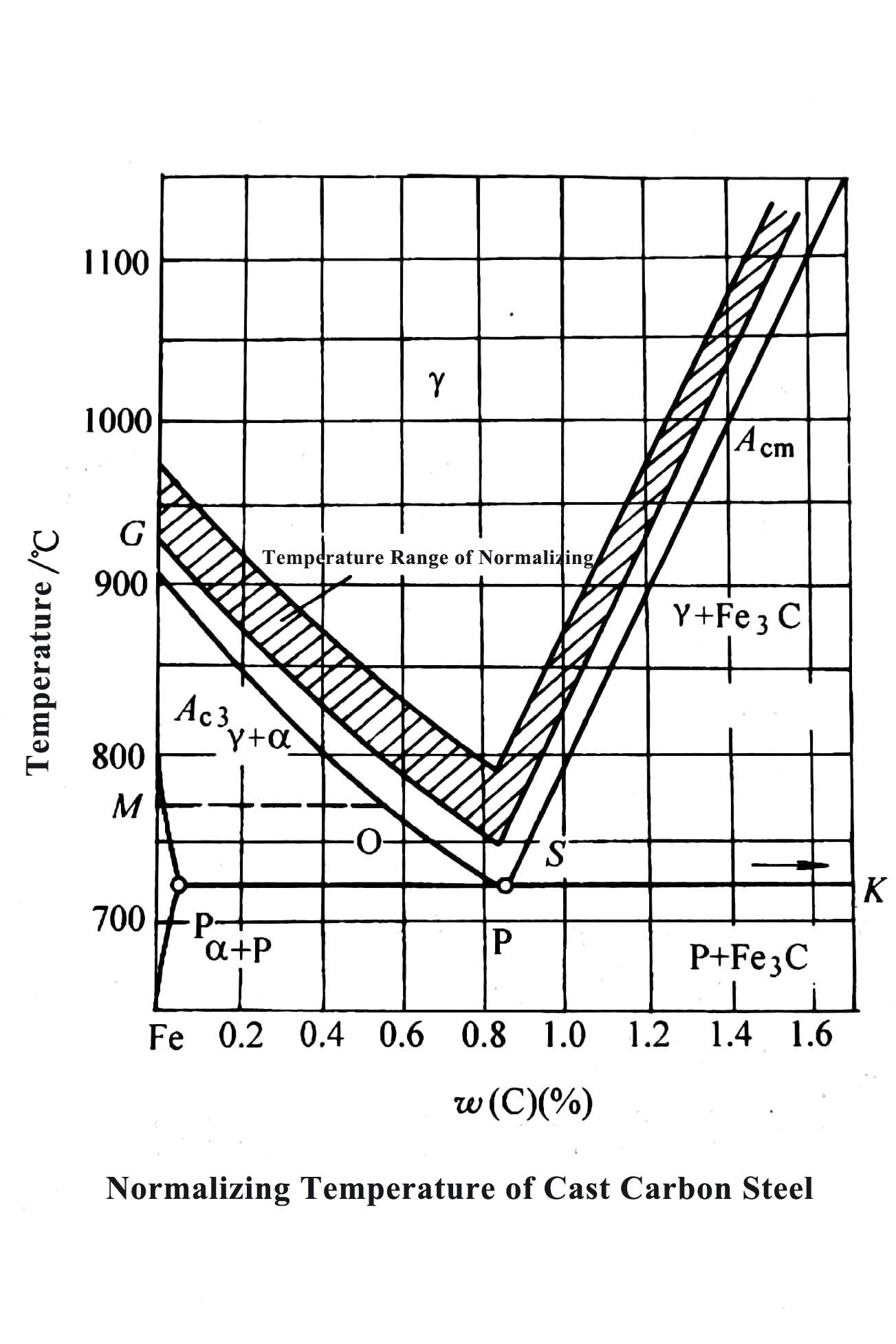

2) Normalizing

Normalizing is a heat treatment in which the steel is heated to 30 °C - 50 °C above Ac3 (hypoeutectoid steel) and Acm (hypereutectoid steel), and after a period of heat preservation, it is cooled to room temperature in air or in forced air. method. Normalizing has a faster cooling rate than annealing, so the normalized structure is finer than the annealed structure, and its strength and hardness are also higher than that of the annealed structure. Due to the short production cycle and high equipment utilization of normalizing, normalizing is widely used in various steel castings.

The purpose of normalizing is divided into the following three categories:

(1) Normalizing as the final heat treatment

For metal castings with low strength requirements, normalizing can be used as the final heat treatment. Normalizing can refine the grains, homogenize the structure, reduce the ferrite content in the hypoeutectoid steel, increase and refine the pearlite content, thereby improving the strength, hardness and toughness of the steel.

(2) Normalizing as a pre-heat treatment

For steel castings with larger sections, normalizing before quenching or quenching and tempering (quenching and high temperature tempering) can eliminate Widmanstatten structure and banded structure, and obtain a fine and uniform structure. For the network cementite present in carbon steels and alloy tool steels with a carbon content greater than 0.77%, normalizing can reduce the content of secondary cementite and prevent it from forming a continuous network, preparing the organization for spheroidizing annealing .

(3) Improve cutting performance

Normalizing can improve the cutting performance of low carbon steel. The hardness of low carbon steel castings is too low after annealing, and it is easy to stick to the knife during cutting, resulting in excessive surface roughness. Through normalizing heat treatment, the hardness of low carbon steel castings can be increased to 140 HBW - 190 HBW, which is close to the optimal cutting hardness, thereby improving the cutting performance.

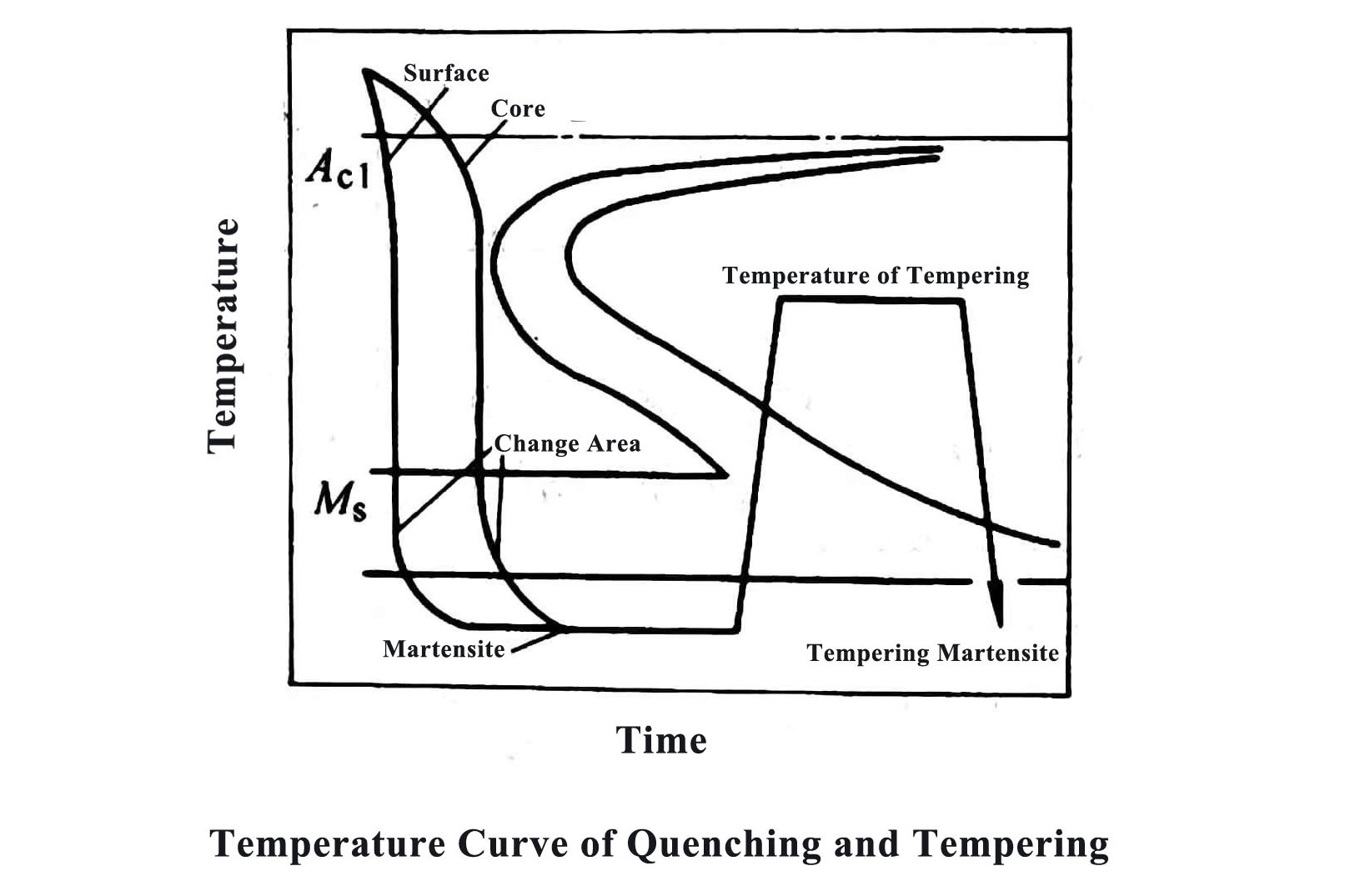

3) Quenching

Quenching is a heat treatment process in which steel castings are heated to a temperature above Ac3 or Ac1, and then rapidly cooled after holding for a period of time to obtain a complete martensitic structure. The steel castings should be tempered in time after the hottest to eliminate the quenching stress and obtain the required comprehensive mechanical properties.

(1) Quenching temperature

The quenching heating temperature of hypoeutectoid steel is 30℃-50℃ above Ac3; the quenching heating temperature of eutectoid steel and hypereutectoid steel is 30℃-50℃ above Ac1. Hypoeutectoid carbon steel is heated at the above-mentioned quenching temperature in order to obtain fine grained austenite, and fine martensite structure can be obtained after quenching. The eutectoid steel and hypereutectoid steel have been spheroidized and annealed before the quenching and heating, so after heating to 30℃-50℃ above Ac1 and incompletely austenitized, the structure is austenite and partially undissolved fine-grained infiltration Carbon body particles. After quenching, austenite is transformed into martensite, and undissolved cementite particles are retained. Due to the high hardness of cementite, it not only does not reduce the hardness of steel, but also improves its wear resistance. The normal quenched structure of hypereutectoid steel is fine flaky martensite, and fine granular cementite and a small amount of retained austenite are evenly distributed on the matrix. This structure has high strength and wear resistance, but also has a certain degree of toughness.

(2) Cooling medium for quenching heat treatment process

The purpose of quenching is to obtain complete martensite. Therefore, the cooling rate of the cast steel during quenching must be greater than the critical cooling rate of the cast steel, otherwise the martensite structure and corresponding properties cannot be obtained. However, too high a cooling rate can easily lead to deformation or cracking of the casting. In order to meet the above requirements at the same time, the appropriate cooling medium should be selected according to the material of the casting, or the method of staged cooling should be adopted. In the temperature range of 650℃-400℃, the isothermal transformation rate of supercooled austenite of steel is the largest. Therefore, when the casting is quenched, rapid cooling should be ensured in this temperature range. Below the Ms point, the cooling rate should be slower to prevent deformation or cracking. Quenching medium usually adopts water, aqueous solution or oil. In the stage quenching or austempering, the commonly used media include hot oil, molten metal, molten salt or molten alkali.

The cooling capacity of water in the high temperature zone of 650℃-550℃ is strong, and the cooling capacity of water in the low temperature zone of 300℃-200℃ is very strong. Water is more suitable for quenching and cooling of carbon steel castings with simple shapes and large cross-sections. When used for quenching and cooling, the water temperature is generally not higher than 30°C. Therefore, it is generally adopted to strengthen the water circulation to keep the water temperature within a reasonable range. In addition, heating salt (NaCl) or alkali (NaOH) in water will greatly increase the cooling capacity of the solution.

The main advantage of oil as a cooling medium is that the cooling rate in the low temperature zone of 300℃-200℃ is much lower than that of water, which can greatly reduce the internal stress of the quenched workpiece and reduce the possibility of deformation and cracking of the casting. At the same time, the cooling capacity of oil in the high temperature range of 650℃-550℃ is relatively low, which is also the main disadvantage of oil as a quenching medium. The temperature of quenching oil is generally controlled at 60℃-80℃. Oil is mainly used for the quenching of alloy steel castings with complex shapes and the quenching of carbon steel castings with small cross-sections and complex shapes.

In addition, molten salt is also commonly used as a quenching medium, which becomes a salt bath at this time. The salt bath is characterized by a high boiling point and its cooling capacity is between water and oil. Salt bath is often used for austempering and stage quenching, as well as for the treatment of castings with complex shapes, small dimensions and strict deformation requirements.

4) Tempering

Tempering refers to a heat treatment process in which the quenched or normalized steel castings are heated to a selected temperature lower than the critical point Ac1, and after holding for a period of time, they are cooled at an appropriate rate. Tempering heat treatment can transform the unstable structure obtained after quenching or normalizing into a stable structure to eliminate stress and improve the plasticity and toughness of steel castings. Generally, the heat treatment process of quenching and high temperature tempering treatment is called quenching and tempering treatment. The quenched steel castings must be tempered in time, and the normalized steel castings should be tempered when necessary. The performance of steel castings after tempering depends on the tempering temperature, time and number of times. The increase of tempering temperature and the extension of holding time at any time can not only relieve the quenching stress of steel castings, but also transform unstable quenched martensite into tempered martensite, troostite or sorbite. The strength and hardness of steel castings are reduced, and the plasticity is significantly improved. For some medium alloy steels with alloying elements that strongly form carbides (such as chromium, molybdenum, vanadium and tungsten, etc.), the hardness increases and toughness decreases when tempering at 400℃-500℃. This phenomenon is called secondary hardening, that is, the hardness of the cast steel in the tempered state reaches the maximum. In actual production, medium alloy cast steel with secondary hardening characteristics needs to be tempered many times.

(1) Low temperature tempering

The temperature range of low temperature tempering is 150℃-250℃. Low temperature tempering can obtain tempered martensite structure, which is mainly used for quenching high carbon steel and quenching high alloy steel. Tempered martensite refers to the structure of cryptocrystalline martensite plus fine granular carbides. The structure of hypoeutectoid steel after low temperature tempering is tempered martensite; the structure of hypereutectoid steel after low temperature tempering is tempered martensite + carbides + retained austenite. The purpose of low temperature tempering is to appropriately improve the toughness of quenched steel while maintaining high hardness (58HRC-64HRC), high strength and wear resistance, while significantly reducing the quenching stress and brittleness of steel castings.

(2) Medium temperature tempering

The tempering temperature of medium temperature is generally between 350℃-500℃. The structure after tempering at medium temperature is a large amount of fine-grained cementite dispersed and distributed on the ferrite matrix, that is, the tempered troostite structure. The ferrite in the tempered troostite structure still retains the shape of martensite. The internal stress of steel castings after tempering is basically eliminated, and they have higher elastic limit and yield limit, higher strength and hardness, and good plasticity and toughness.

(3) High temperature tempering

The high temperature tempering temperature is generally 500°C-650°C, and the heat treatment process that combines quenching and subsequent high temperature tempering is usually called quenching and tempering treatment. The structure after high temperature tempering is tempered sorbite, that is, fine-grained cementite and ferrite. The ferrite in the tempered sorbite is polygonal ferrite that undergoes recrystallization. Steel castings after high temperature tempering have good comprehensive mechanical properties in terms of strength, plasticity and toughness. High temperature tempering is widely used in medium carbon steel, low alloy steel, and various important structural parts with complex forces.

5) Solid SolutionTtreatment

The main purpose of solution treatment is to dissolve carbides or other precipitated phases in solid solution to obtain a supersaturated single-phase structure. Castings of austenitic stainless steel, austenitic manganese steel and precipitation hardening stainless steel should generally be solid solution treated. The choice of solution temperature depends on the chemical composition and phase diagram of the cast steel. The temperature of austenitic manganese steel castings is generally 1000 ℃ - 1100 ℃; the temperature of austenitic chromium-nickel stainless steel castings is generally 1000℃-1250℃.

The higher the carbon content in cast steel and the more insoluble alloying elements, the higher its solid solution temperature should be. For precipitation hardening steel castings containing copper, the hardness of the steel castings increases due to the precipitation of hard copper-rich phases in the as-cast state during cooling. In order to soften the structure and improve the processing performance, the steel castings need to be solid solution treated. Its solid solution temperature is 900℃-950℃.

6) Precipitation Hardening Treatment

Precipitation hardening treatment is a dispersion strengthening treatment carried out within the tempering temperature range, also known as artificial aging. The essence of precipitation hardening treatment is that at higher temperatures, carbides, nitrides, intermetallic compounds and other unstable intermediate phases are precipitated from supersaturated solid solution and dispersed in the matrix, thus making the cast steel comprehensive Improved mechanical properties and hardness.

The temperature of aging treatment directly affects the final performance of steel castings. If the aging temperature is too low, the precipitation hardening phase will precipitate slowly; if the aging temperature is too high, the accumulation of the precipitated phase will cause overaging, and the best performance will not be obtained. Therefore, the foundry should select the appropriate aging temperature according to the cast steel grade and the specified performance of the steel casting. The aging temperature of austenitic heat-resistant cast steel is generally 550℃-850℃; the aging temperature of high-strength precipitation hardening cast steel is generally 500℃.

7) Stress Relief Treatment

The purpose of stress relief heat treatment is to eliminate casting stress, quenching stress and stress formed by machining, so as to stabilize the size of the casting. The stress relief heat treatment is generally heated to 100°C-200°C below Ac1, then kept for a period of time, and finally cooled with the furnace. The structure of the steel casting did not change during the stress relief process. Carbon steel castings, low-alloy steel castings and high-alloy steel castings can all be subjected to stress relief treatment.

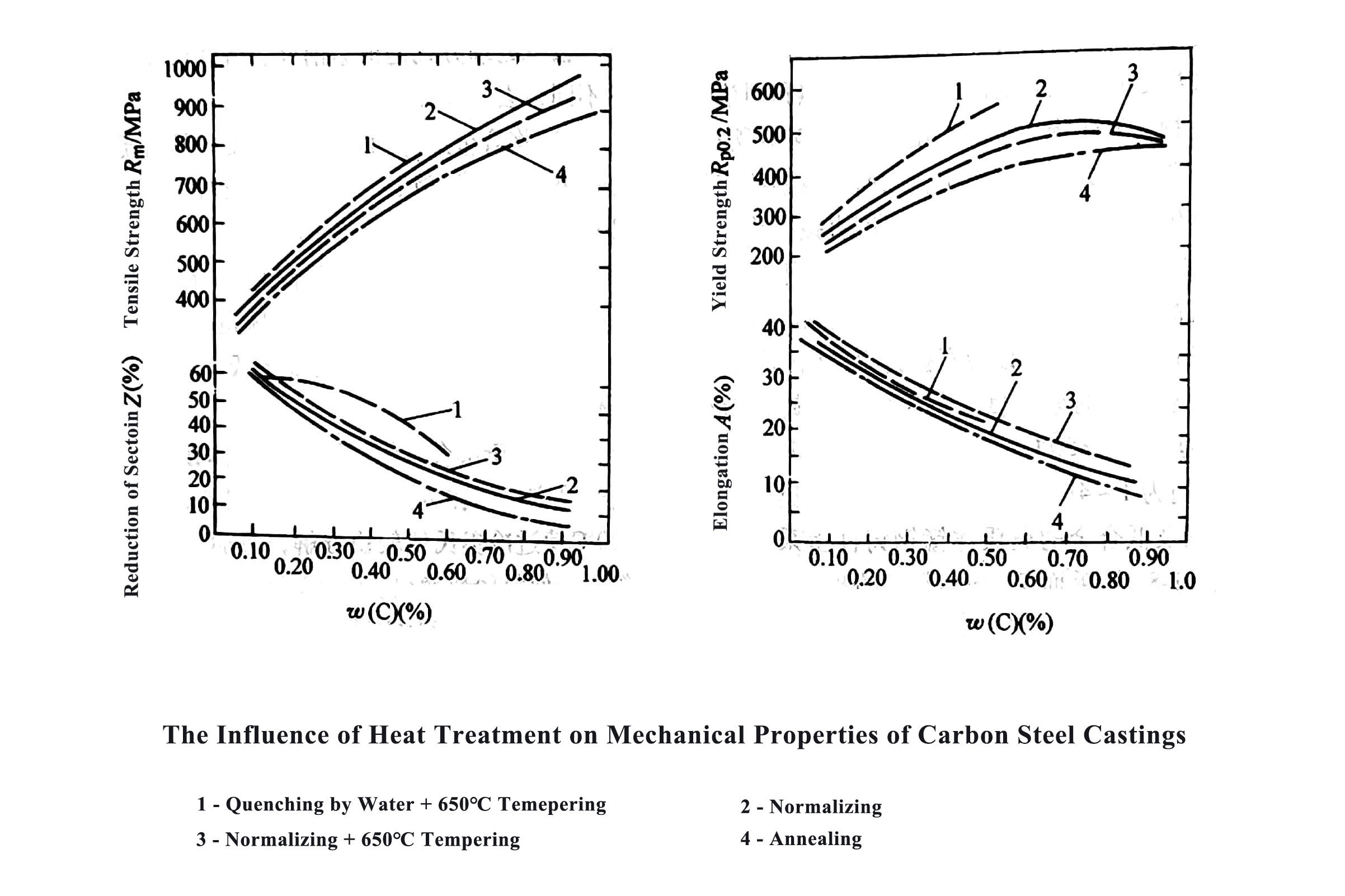

4. The Effect of Heat Treatment on the Properties of Steel Castings

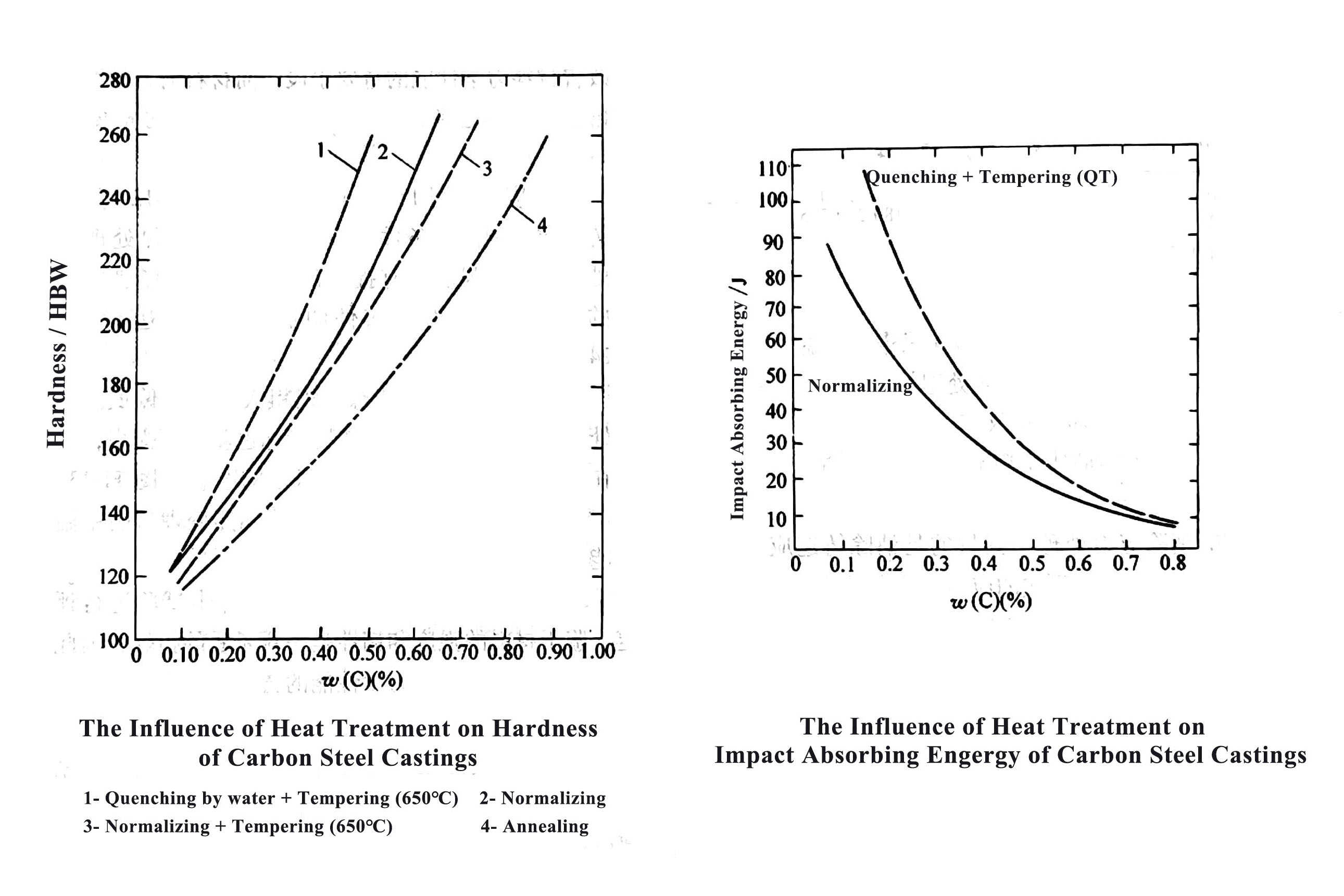

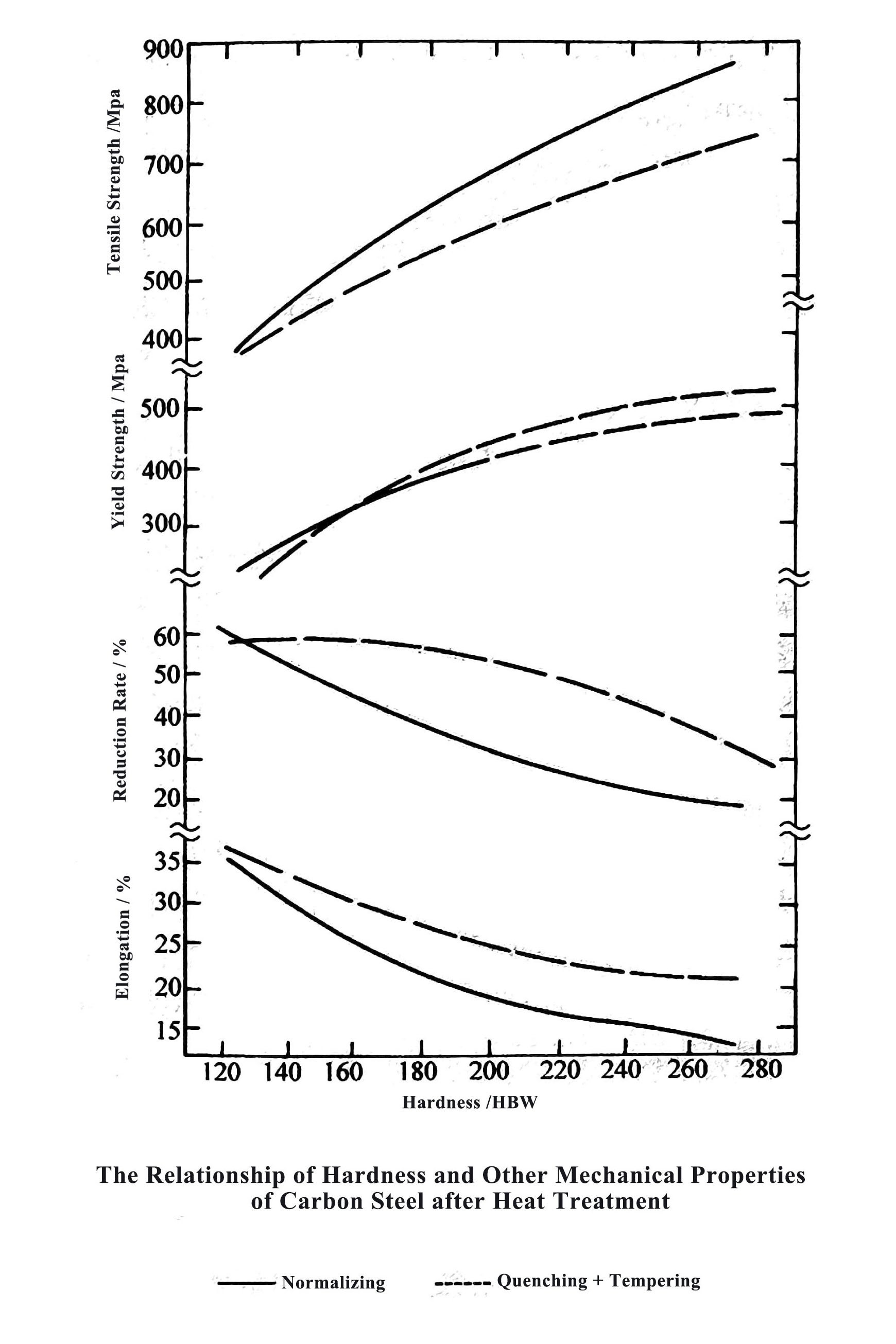

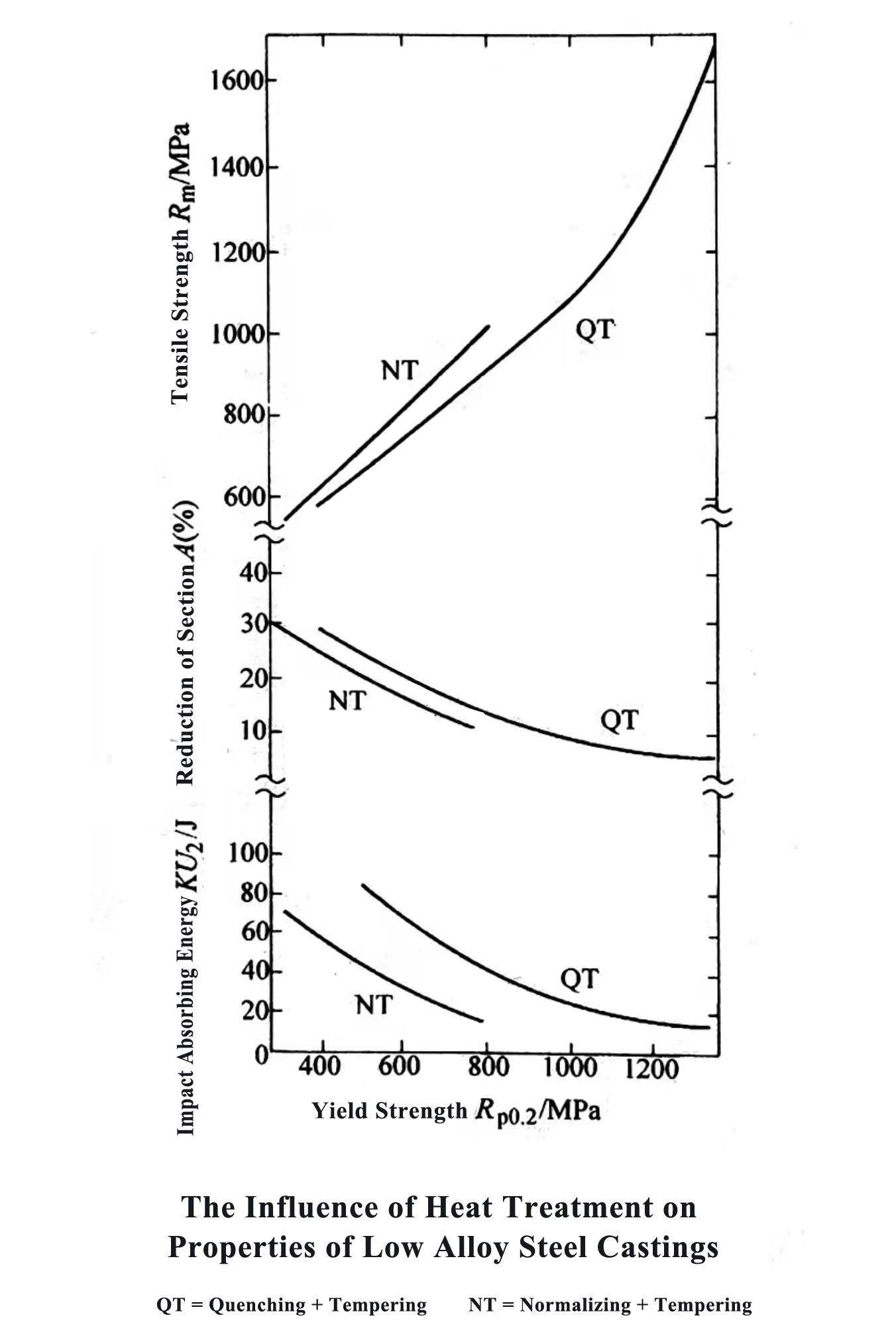

In addition to the performance of steel castings depending on the chemical composition and casting process, different heat treatment methods can also be used to make it have excellent comprehensive mechanical properties. The general purpose of the heat treatment process is to improve the quality of the castings, reduce the weight of the castings, extend the service life and reduce costs. Heat treatment is an important means to improve the mechanical properties of castings; the mechanical properties of castings are an important indicator for judging the effect of heat treatment. In addition to the following properties, the foundry must also consider factors such as processing procedures, cutting performance and the use requirements of the castings when heat-treating steel castings.

1) The Influence of Heat Treatment on the Strength of Castings

Under the condition of the same cast steel composition, the strength of steel castings after different heat treatment processes has a tendency to increase. Generally speaking, the tensile strength of carbon steel castings and low alloy steel castings can reach 414 Mpa-1724 MPa after heat treatment.

2) The Effect of Heat Treatment on the Plasticity of Steel Castings

The as-cast structure of the steel castings is coarse and the plasticity is low. After heat treatment, its microstructure and plasticity will be improved accordingly. Especially the plasticity of steel castings after quenching and tempering treatment (quenching + high temperature tempering) will be significantly improved.

3) Toughness of Steel Castings

The toughness index of steel castings is often evaluated by impact tests. Since the strength and toughness of steel castings are a pair of contradictory indicators, the foundry must make comprehensive considerations to select a suitable heat treatment process in order to achieve the comprehensive mechanical properties required by customers.

4) The Effect of Heat Treatment on the Hardness of Castings

When the hardenability of the cast steel is the same, the hardness of the cast steel after heat treatment can roughly reflect the strength of the cast steel. Therefore, the hardness can be used as an intuitive index to estimate the performance of cast steel after heat treatment. Generally speaking, the hardness of carbon steel castings can reach 120 HBW - 280 HBW after heat treatment.

Post time: Jul-12-2021