Cast iron, which mainly covers gray cast iron, ductile cast iron, cast mealleable iron and other high alloy cast iron, is widely used in RMC Casting Foundry. The cast iron castings play an important role in modern industries. To select the right and suitable casting processes made by cast iron will help you to get the iron castings at a lower costs and short leadtime.

Here in the following we propose some principles or factors when we choose suitable casting processes for cast iron materials. Generally speaking, the most widely used iron casting process is sand casting, followed by special casting methods, such as metal mold casting, investment casting, shell moulding casting, lost foam casting and vacuum casting.

1- Sand Casting Should be the First Choice

Mainly due to low cost and simple production of sand casting process, sand casting has taken about 60% to 70% of the total casting production, and about 70% of which is green sand casting. When the green sand can not meet the requirements and then you could consider the use of dry sand or other sand. The weight range of green sand casting is from several kilograms to hundreds of kilograms, while the production of dry clay casting can weigh several tons.

The sand casting process uses kinds of sand for making casting mold. It can also be divided into three types:

1) Green Sand Casting, which use the wet (green) sand to form the mold.

2) Resin Coated Sand Casting and No-bake Sand Mold Casting (Self-hardening Resin Sand Casting), which use chemical bonded materials to help to form the molding systems.

3) Dry Sand Casting, which mainly use the dry without chemical mateials for molding. The dry sand casting process mainly refers to lost foam casting and vacuum casting.

Generally speaking, for medium and large iron castings, self-hardening resin sand casting would be the good option. But regarding the alloy steel and carbon steel materials, we could choose the water glass sand. This can get accurate dimensions, smooth surface of the castings, while with a lower costs than silica sol investment casting process.

The accuracy, surface finish, material density and microstructure, mechanical properties may not reach the strict requriemenets if you have special and high expectations. In this case, other casting methods such as silica sol or water glass investment casting, die casting, low pressure casting, lost foam casting and vacuum casting should be taken into our eyes.

2- Think About The Annual Demand

If your annual demand is high, the automatic molding line should be the best choice because of its big production capacity and steady quality. And this method could reach a low average costs only if the required quantity is big enough. While, molding by hand will save your costs if your quantity is not so big, or your desired castings are medium-sized or large-sized.

However, the resin sand mould (shell moulding) casting process is also suitable for iron castings of large size. Moreover, the shell casting have better finish and higher quality then green sand casting processes.

The other processes such as low pressure die casting, die casting, centrifugal casting is only suitable for mass production with big quantity because of expensive equipment and toolings.

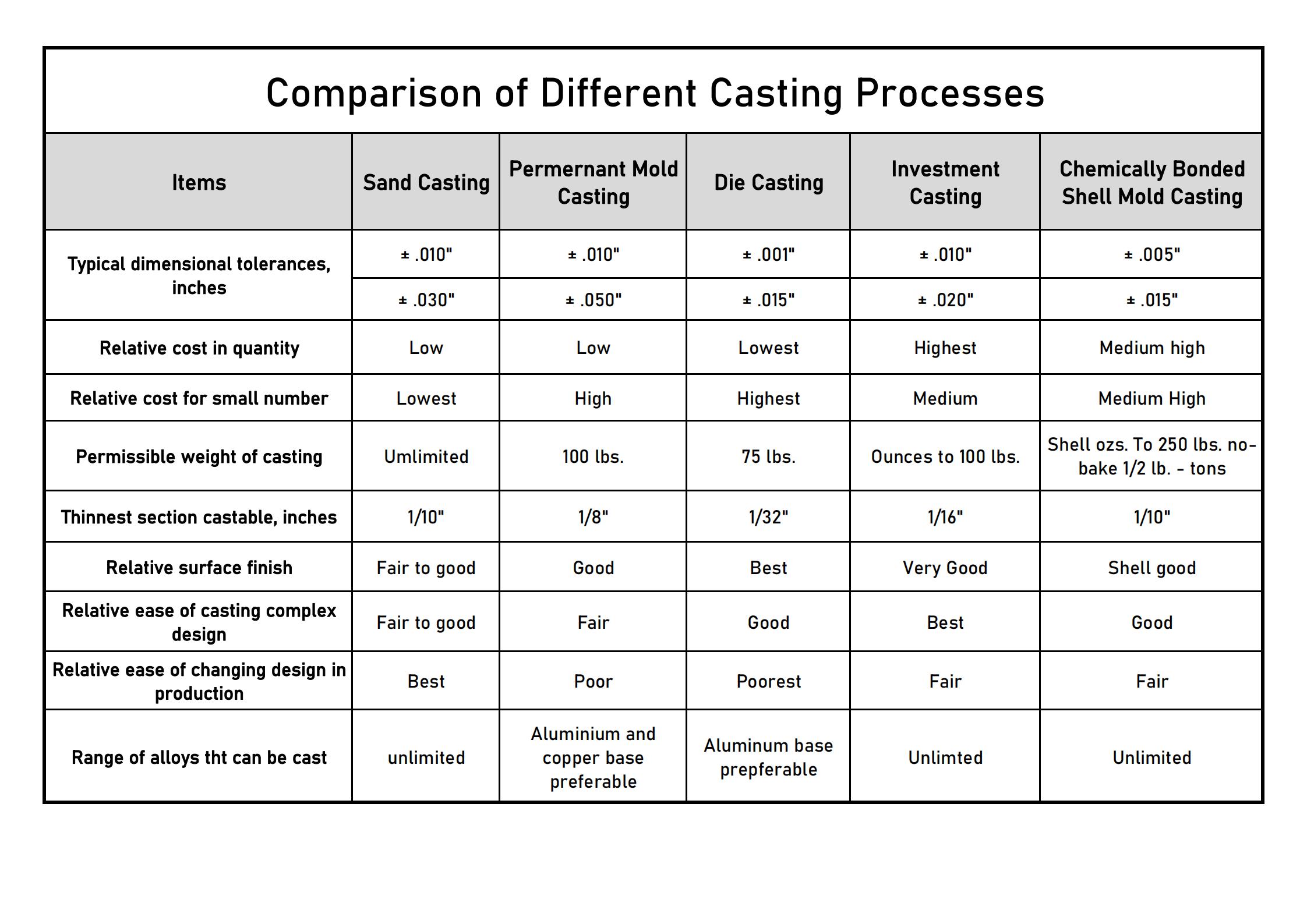

3- Dimensional Tolerances and Surface Quality Count

In the process of selecting the casting process for the cast iron material, dimensional accuracy and surface quality are also critical. Choosing a precision casting process will reduce the need for machining, even without machining. This requires a comprehensive consideration of the balance between the increase in casting costs and the reduction in machining. Based on our many years of experience, our company’s engineers can select the most suitable and economical casting process for you.

Post time: Jan-28-2021