Core Boxes

In foundry production, except for a few simple castings that do not require cores to form the internal cavities or holes, most castings use cores to form their inner structures. A core box is the necessary mold for manufacturing cores. Its dimensional accuracy and structural reasonableness greatly influence both the quality of the cores and the efficiency of core-making.

1. Calculation of Core Box Cavity Dimensions

The cavity dimension of a core box, i.e., the core dimension, should be calculated based on the casting process drawing.

The formula is:

Core box cavity dimension = (part dimensions ± process allowance) × (1 ± casting shrinkage rate)

Explanation of the “±” usage:

“+” is applied when the process allowance increases the core size.

“–” is applied when the process allowance decreases the core size.

2. Structural Forms of Core Boxes

Core boxes generally have three structural forms: integral, split, and collapsible.

• Integral core box: All four walls of the box are fixed and cannot be dismantled. It usually has an open sand-filling surface, and the core can be released by turning the box upside down, aided by a draft angle in the ejection direction. This type is simple, easy to operate, and suitable for producing simple, shallow cores.

• Split core box: Made of two or more parts with positioning and clamping devices. The box is locked before filling, and after ramming, the box is dismantled to remove the core. Depending on the parting surface, it can be horizontal or vertical.

• Collapsible core box: Widely used in practice, it consists of an inner and outer wall. The inner wall forms the shape and size of the core, while the outer wall acts as a frame to fix the inner wall. After the core is made, the box is turned over to remove the outer frame, and then the inner sections are separated from the core from different directions. This structure is suitable for complex cores, though its accuracy is relatively lower.

3. Types of Core Boxes

Various types of core boxes are used in production, classified by the material used:

• Wooden core boxes: Made of wood, mainly used for hand core-making or self-setting sand cores in single-piece and small-batch production.

• Metal core boxes: Typically made of aluminum alloy or gray cast iron, used for mass production of cores or when special requirements are placed on the process. They improve both accuracy and durability.

• Plastic core boxes: Share similar advantages with plastic patterns and are suitable for manufacturing geometrically complex cores with intricate parting surfaces.

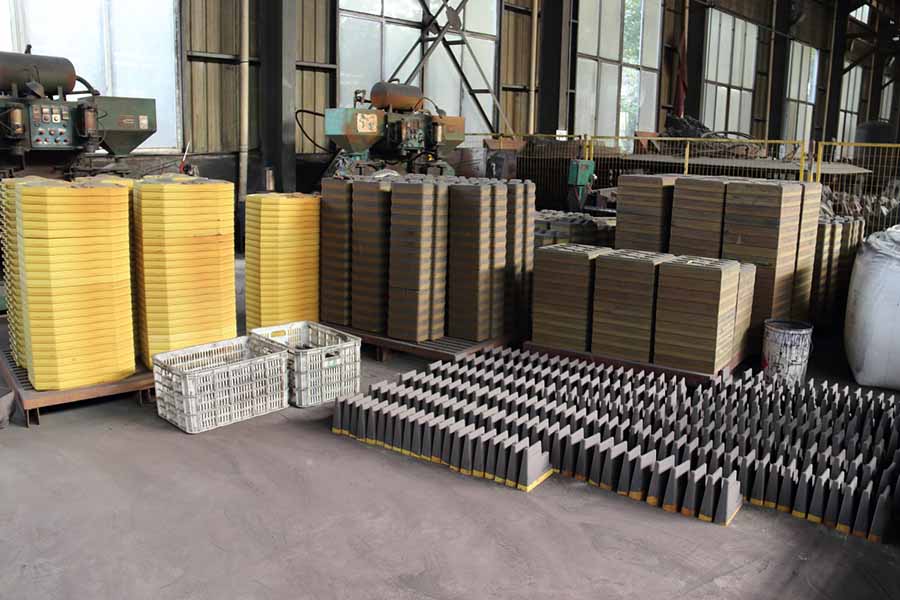

Flasks

A flask is a component of the mold and is used for making and transporting the sand mold.

As essential process equipment in foundry workshops, flask structures must meet both molding process requirements and workshop handling/transport conditions. Proper selection and design of flask structures are critical for ensuring casting quality, improving efficiency, reducing labor intensity, lowering costs, and ensuring safe production.

1. Classification of Flasks

Flasks can be classified in different ways:

By material:

Wooden flasks: Used in hand molding with flask-stripping methods for single-piece or small-batch production.

Aluminum alloy flasks: Unsuitable for pouring due to their low melting point; generally used for flask-stripping molding machines.

Gray cast iron flasks: Strong, easy to manufacture, low-cost, and widely used in production.

Ductile iron flasks: Commonly used on molding lines.

Steel flasks: Higher cost, mostly used in large foundries, especially steel foundries and molding lines.

By structural form:

Ordinary flasks: General-purpose flasks, usually square or rectangular, most widely used.

Special flasks: Designed for specific castings, such as round flasks, which can save molding materials and time.

2. Basic Requirements for Flasks

Although flasks come in various types and sizes, their structures share common characteristics, generally being frame-shaped.

Basic requirements include:

• Inner frame dimensions must ensure adequate molding sand thickness between flask wall and pattern.

• Walls, bands, and ribs should provide sufficient strength and stiffness, while facilitating sand adhesion, riser/gate placement, casting shrinkage, shakeout, and casting removal.

• For venting during drying and pouring, medium and large flasks should have vent holes in the walls.

• Accurate positioning during molding and closing requires structures for installing dowels or bushings.

• For handling: small flasks should have handles, medium and large ones should have lifting shafts or rings, with sufficient strength to ensure safety.

• To prevent lifting or shifting during pouring, flasks should have clamping or locking mechanisms.

• Structures should be simple, lightweight, easy to manufacture, while meeting process and safety requirements.

• Flasks should be standardized, serialized, and generalized as much as possible to reduce variety, lower cost, and facilitate use and management.

Post time: Sep-25-2025