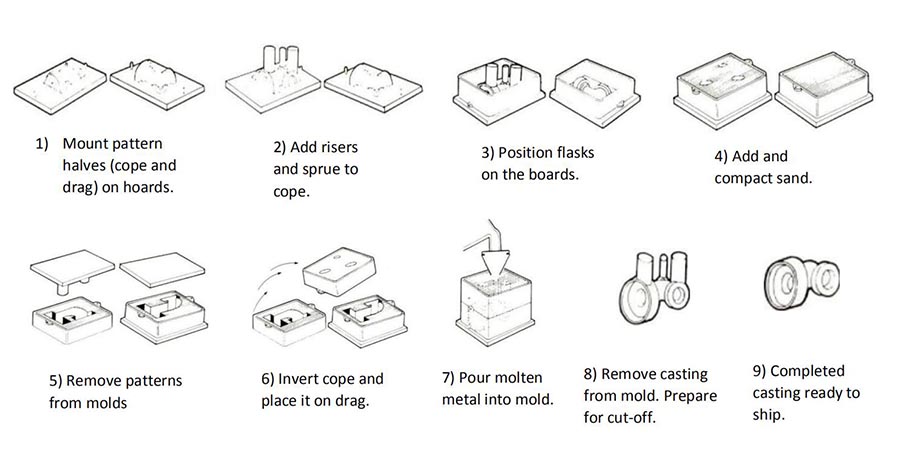

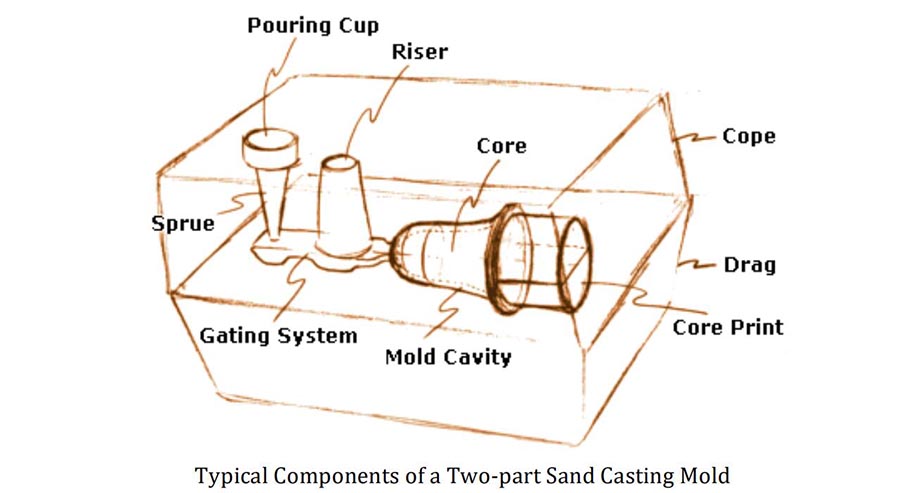

Sand casting process requires the foundry have a strong ability of R&D to design the patterns and molding systems. The ingates, risers and spures are all very important for the success of the finished sand castings. The metal components required for industrial use today are formed using many divergent technologies, such as casting, forging, and machining. Here at Rinborn Machinery Co., we make iron, steel, stainless steel and high alloy castings by pouring molten metal into pre-formed molds, using both the sand casting and investment casting processes. Here is an explanation of how we make castings by sand casting process.

The sand and binder mixture is packed around halves of a pattern constructed from wood, metal or plastic. When the pattern is removed from the sand, an impression or mold of the desired casting remains. Cores may be installed to form internal passages, and then the two mold halves are assembled. Molten metal is then poured into the mold cavity. After solidification, the sand is shaken away from the sand mold castings.

Post time: Jan-06-2021